Airflow sorting machine and multi-product material sorting method

An air separation, multi-product technology, applied in chemical instruments and methods, solid separation, pneumatic shakers, etc., can solve the problems of unsuitable raw coal materials with low gangue content, unable to separate gangue, etc., and achieve the content of gangue. Improve the effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

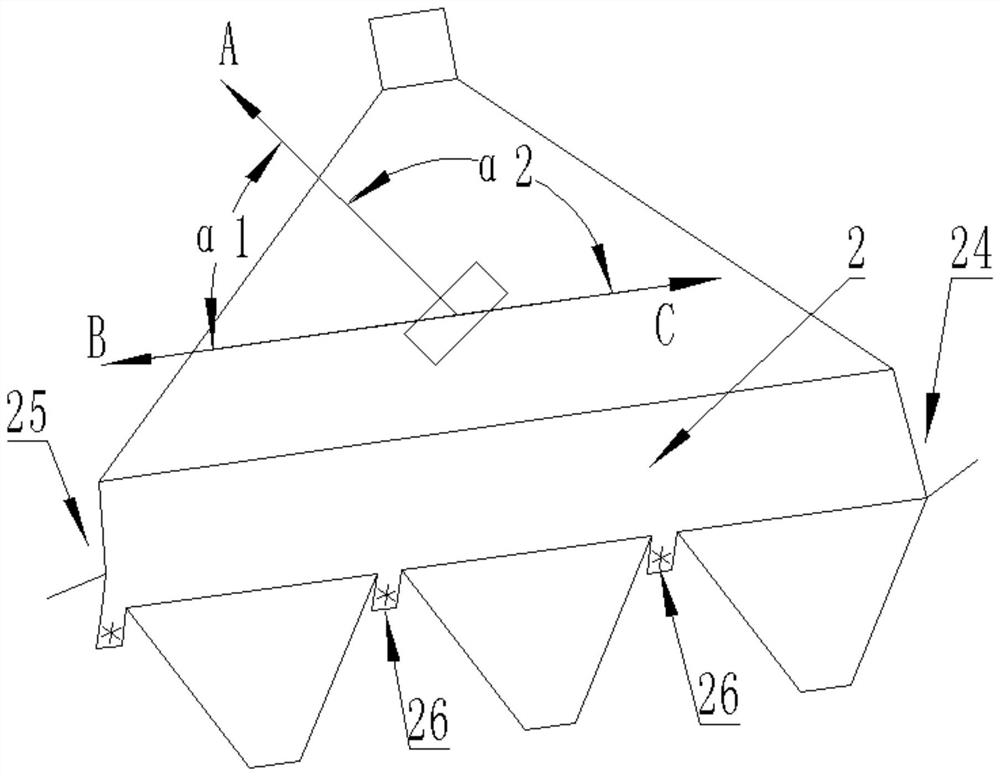

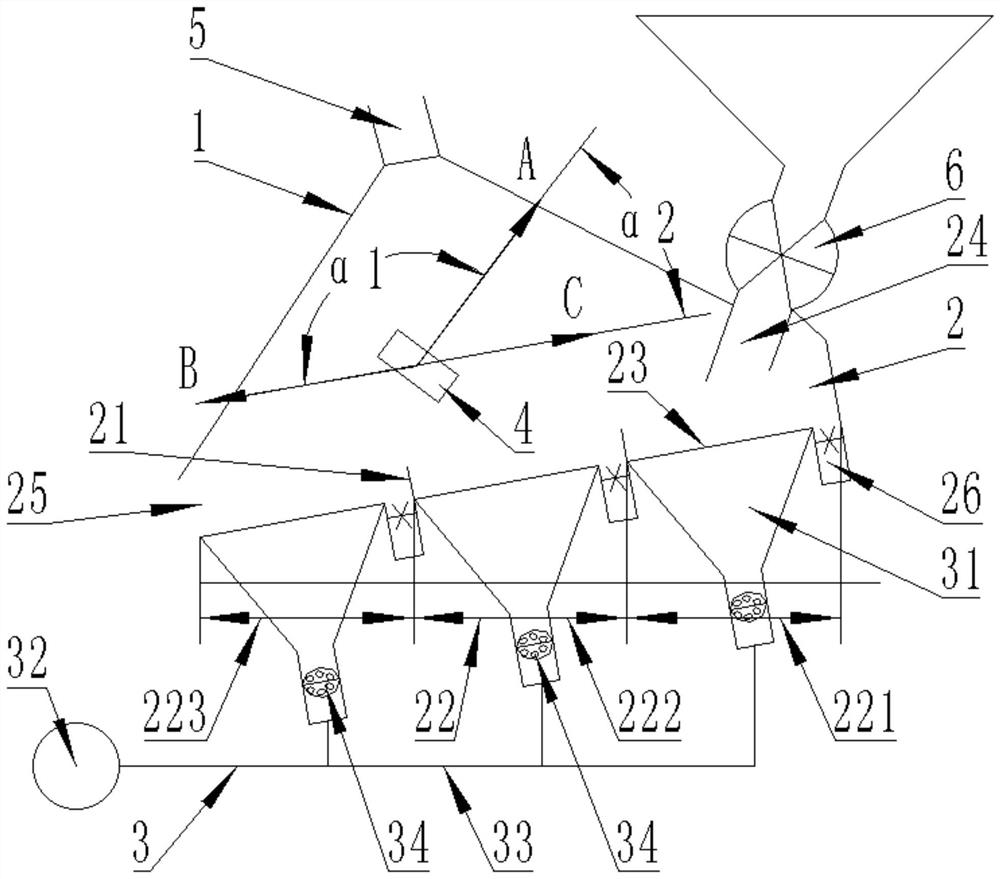

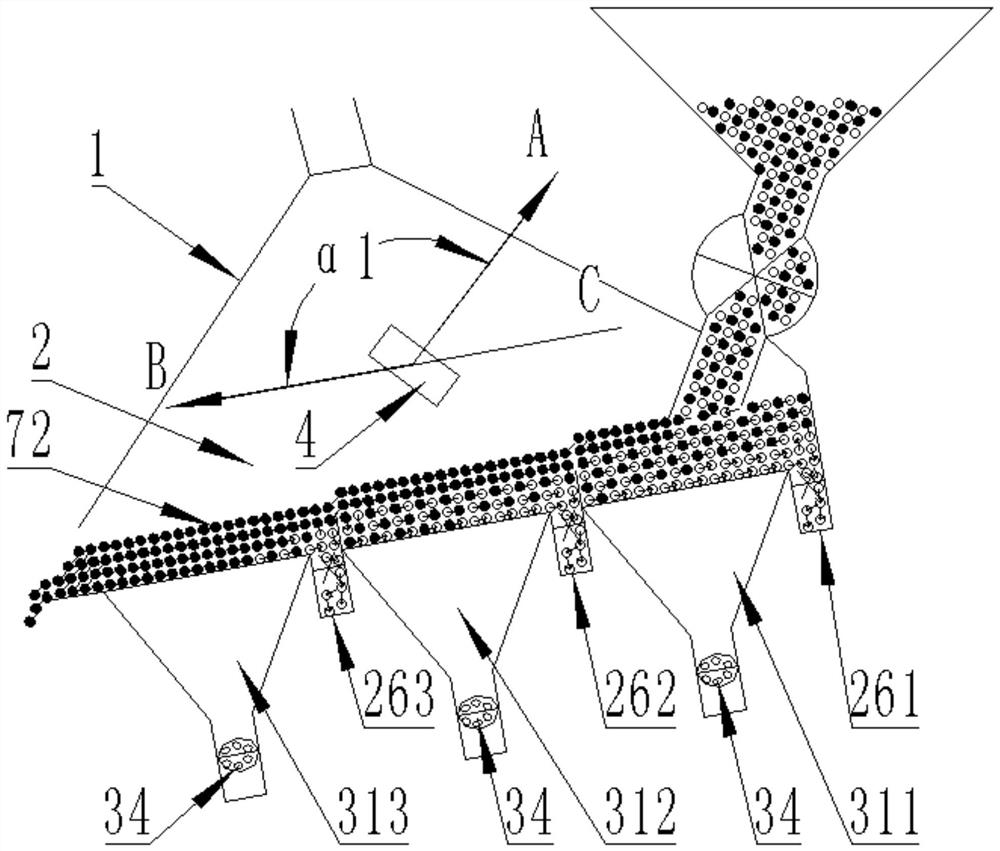

[0036] A kind of airflow separator, described airflow separator comprises sorting bed 2, air supply mechanism 3, vibrating mechanism 4, and one end of sorting bed 2 is provided with feed inlet 24, and the other end of sorting bed 2 is provided with There is a light material discharge port 25, and the bottom of the sorting bed 2 near the end of the direction of the feed port 24 is provided with a gangue discharge port 26, and the sorting bed 2 is inclined downward along the feeding direction, and the inside of the sorting bed 2 The upper layer of light-density materials can slide downwards along the sorting bed 2 under the action of gravity and be discharged from the light material discharge por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com