Plastic spraying equipment capable of preventing paint from caking for tubular electromechanical parts

A part and tubular technology, applied in the field of spraying equipment for preventing coating agglomeration, can solve the problems of long spraying time, uneven coating thickness, insufficient adsorption force, etc., saving spraying time, improving spraying efficiency, saving The effect of energy and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with drawings and embodiments.

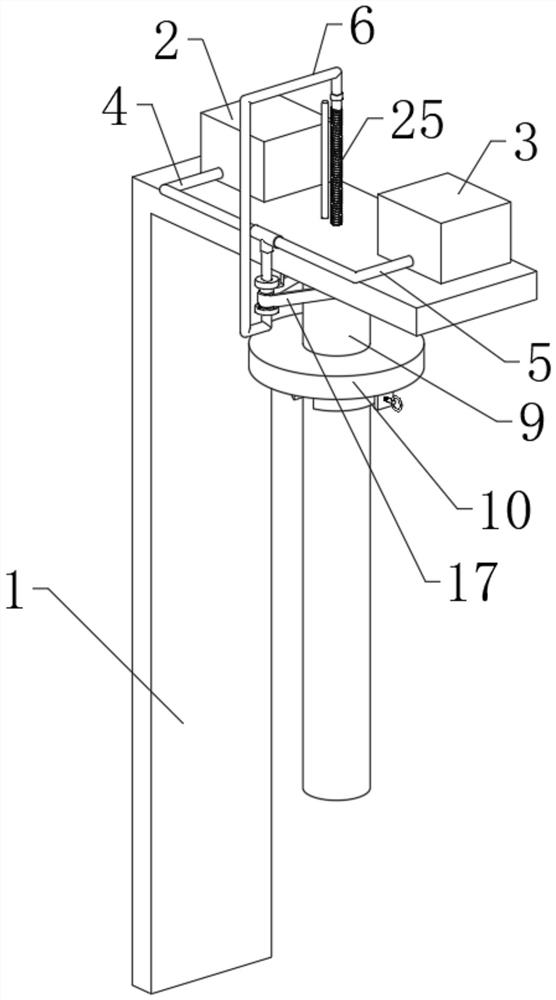

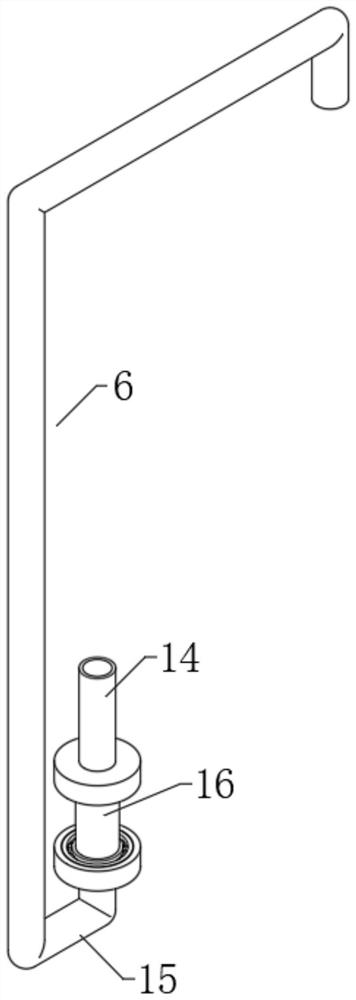

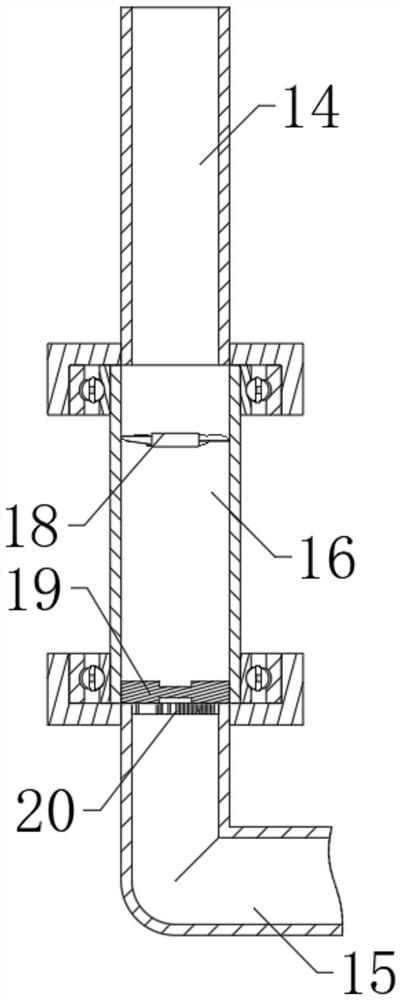

[0051] Such as Figure 1 to Figure 11 Shown, a kind of anti-paint agglomeration spray equipment of tubular electromechanical parts, it includes L-shaped support frame 1, powder feeder 2 and air supply equipment 3, and described powder feeder 2 and air supply equipment 3 are solid Connected to the upper end surface of the L-shaped support frame 1, the discharge port of the powder supply device 2 is connected to the feed port of the first air pipe 4, and the air outlet of the air supply device 3 is connected to the air inlet of the second air pipe 5. The outlet of the first air pipe 4, the air outlet of the second air pipe 5 and the inlet of the third air pipe 6 are communicated by a three-way joint, and the outlet of the third air pipe 6 communicates with the feed port of the spraying unit; The three air pipes 6 are provided with a rotatable crushing unit, and the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com