Flexible cooling equipment for light diffusion plate

A technology of cooling equipment and light diffusion plate, applied in the field of mechanical equipment, can solve the problems of light diffusion plate temperature drop, internal structure damage, product quality decline, etc., and achieve the effects of improving product quality, convenient protection, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

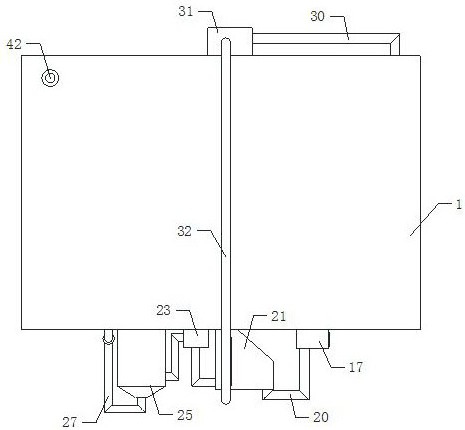

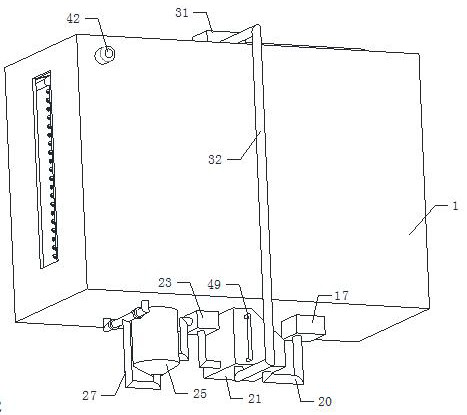

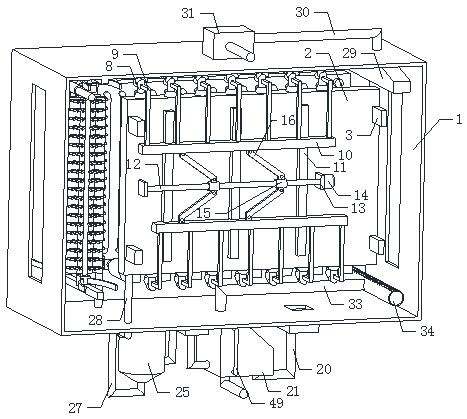

[0022] Such as Figure 1 to Figure 7 As shown, a light diffusion plate flexible cooling device of the present invention, when it is working, the light diffusion plate extruded at high temperature from the outside extends into the working chamber 1 through the material opening on the right side of the working chamber 1, and the air cooling mechanism diffuses the light The plate is blown to cool down, so that its temperature is initially lowered. The light diffusion plate that has been air-cooled moves to the left between the two groups of water-cooling mechanisms, and the refrigeration mechanism is opened. The refrigeration mechanism discharges the cooled water into the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com