Movable pressing frame type laminating machine and rubber plate pressing type laminating method

A laminator and frame-pressing technology, applied in the directions of lamination, lamination device, lamination auxiliary operation, etc., can solve the problems affecting the service life of the rubber sheet, the expansion of the rubber sheet, and the wear of the rubber sheet, so as to save the air. The effect of time, prolong the service life, save the consumption of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiment:

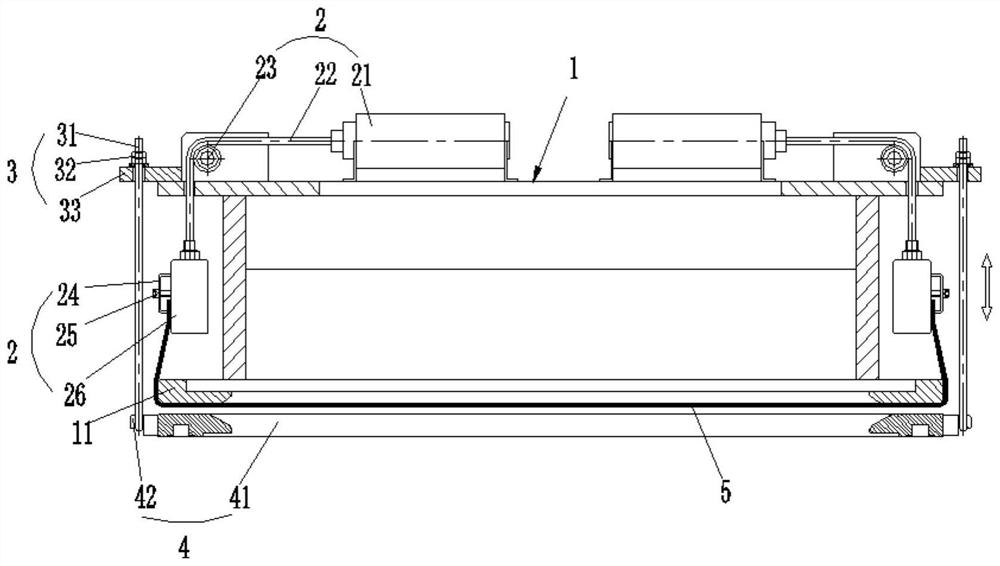

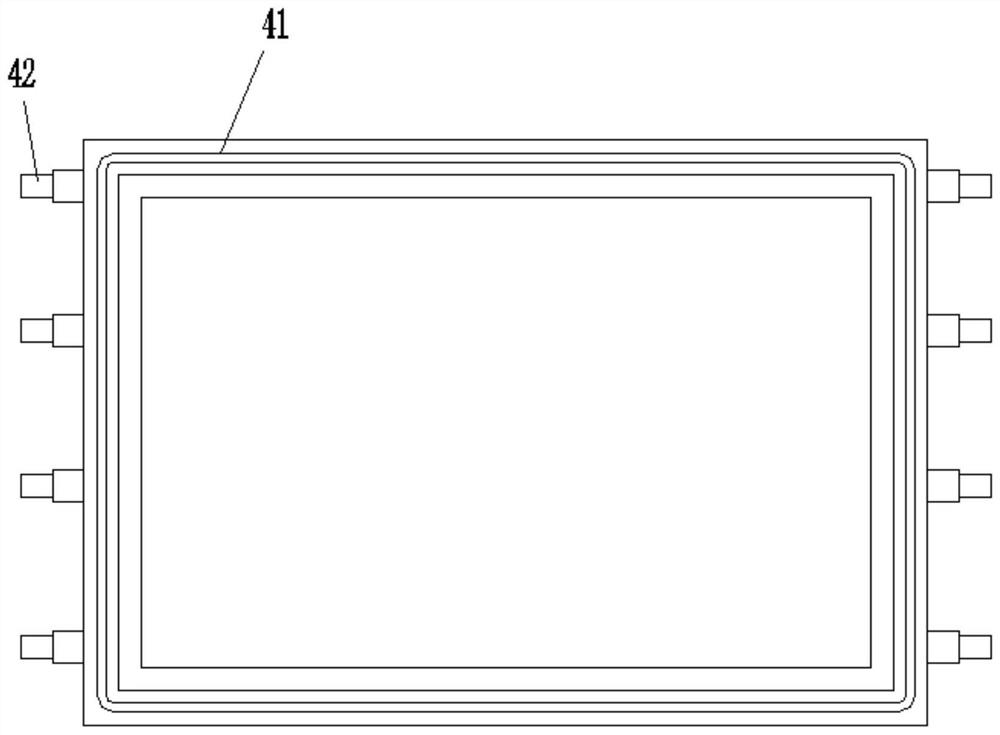

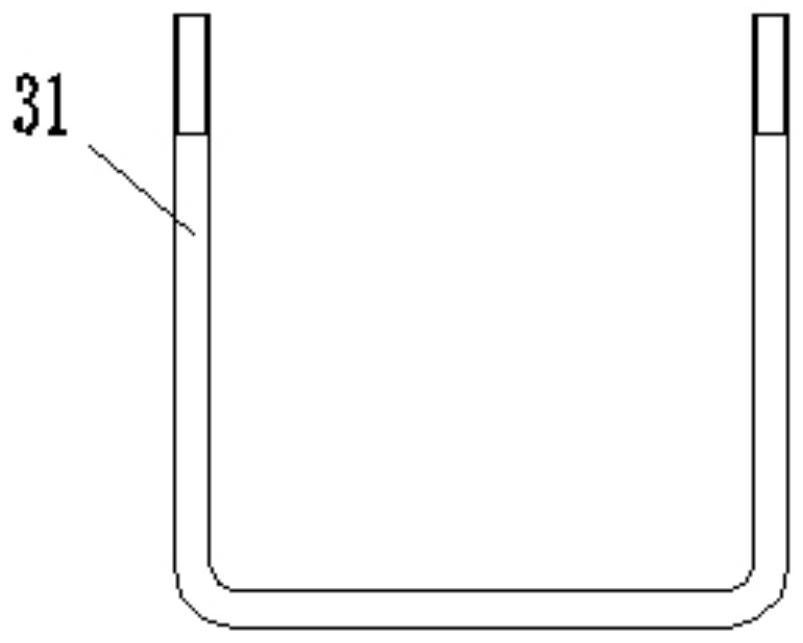

[0024] Such as Figure 1-Figure 3 As shown, the present invention provides a movable press frame type laminator, including a laminator upper cover 1, a lower press frame 4, a rubber plate 5, a press frame connecting device 3 and a tensioning device 2, and the lower press frame 4 is correspondingly arranged Under the upper cover 1 of the laminator, an adhesive sheet 5 is arranged between the upper cover 1 of the laminator and the lower pressing frame 4 . The press frame connecting device 3 can be arranged on four sides of the upper cover 1 of the laminator, and can also be arranged on two opposite sides of the upper cover 1 of the laminator. Pressing frame connecting device 3 comprises telescoping rod 31, connecting plate 33 and limiter, and telescoping rod 31 is arranged vertically, and telescoping rod can be straight-line or U-shaped, and a plurality of telescoping rods ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap