Prefabricated green building system and construction method

A green building and prefabricated technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of cumbersome operation and low work efficiency, and achieve the effect of simple operation, high work efficiency and enhanced connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

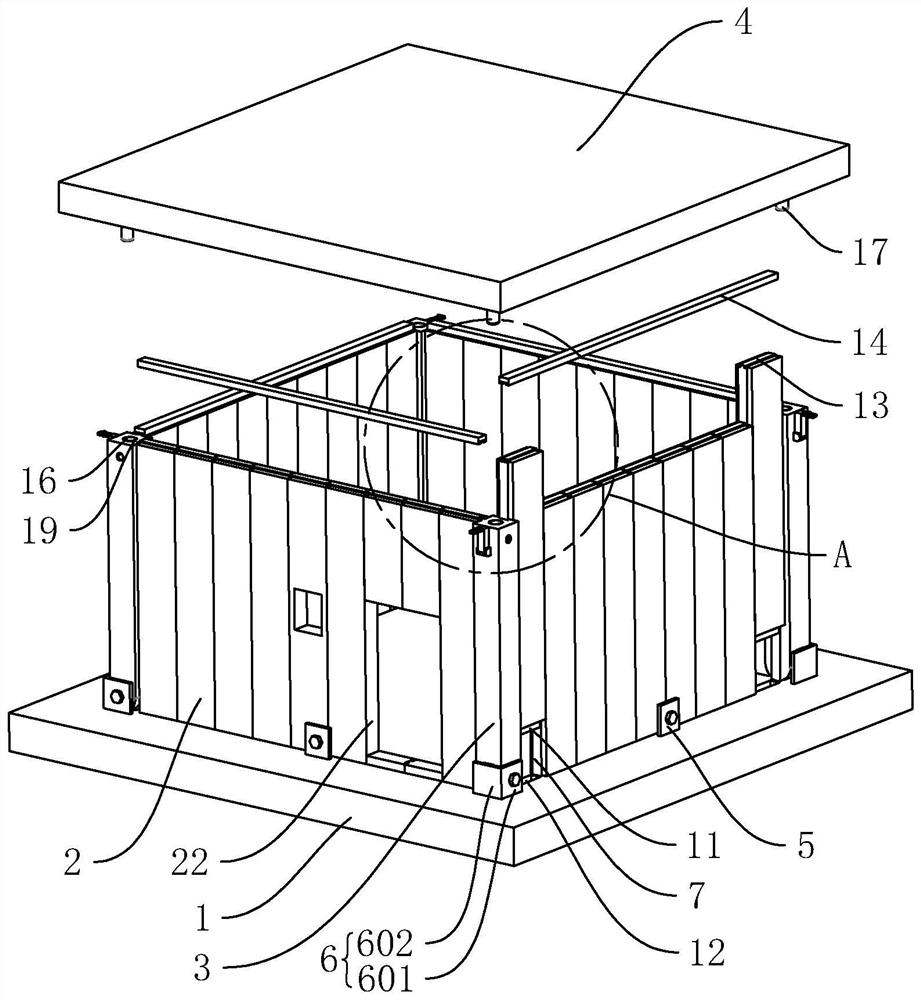

[0043] The following is attached Figure 1-5 The application is described in further detail.

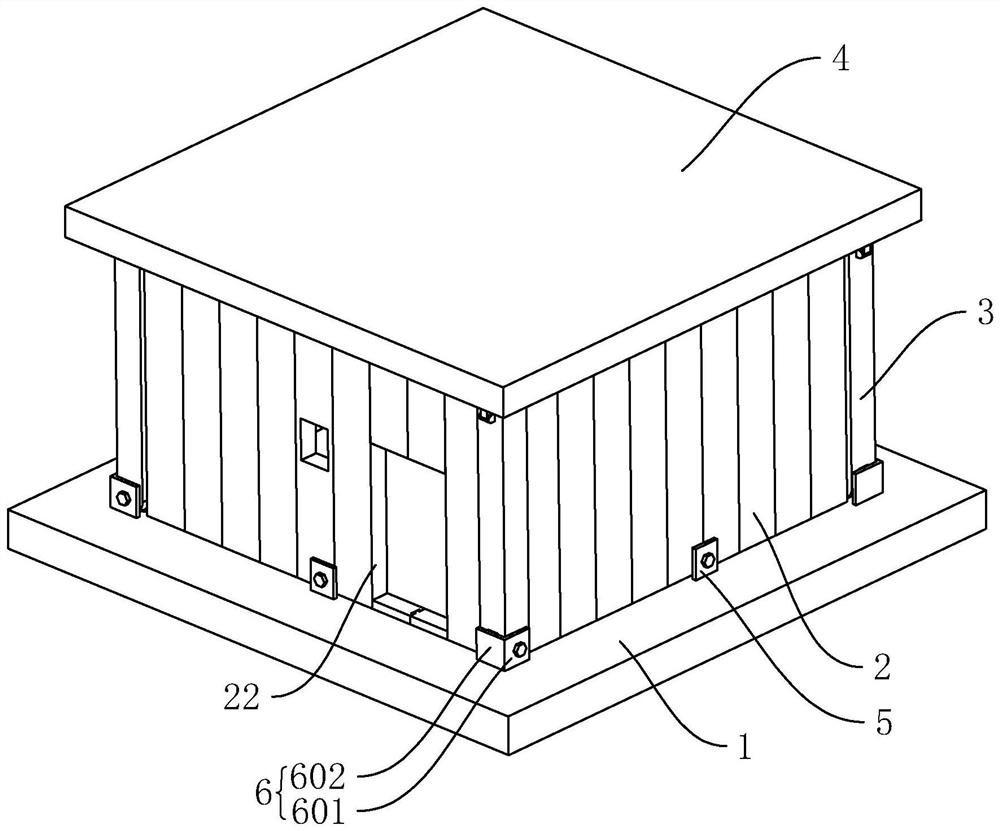

[0044] The embodiment of the present application discloses a prefabricated green building system. refer to figure 1 and figure 2 , the prefabricated green building system includes a base plate 1, a side plate 2, a column 3 and a top plate 4, the base plate 1 is roughly in the shape of a rectangular plate, four columns 3 are provided, the columns 3 are roughly in the shape of a square rod and each column 3 is hinged Installed on the top of the base plate 1, four uprights 3 are arranged near the four corners of the base plate 1 respectively. When each upright 3 is rotated to fit the base plate 1, the top view of the four uprights 3 is roughly square.

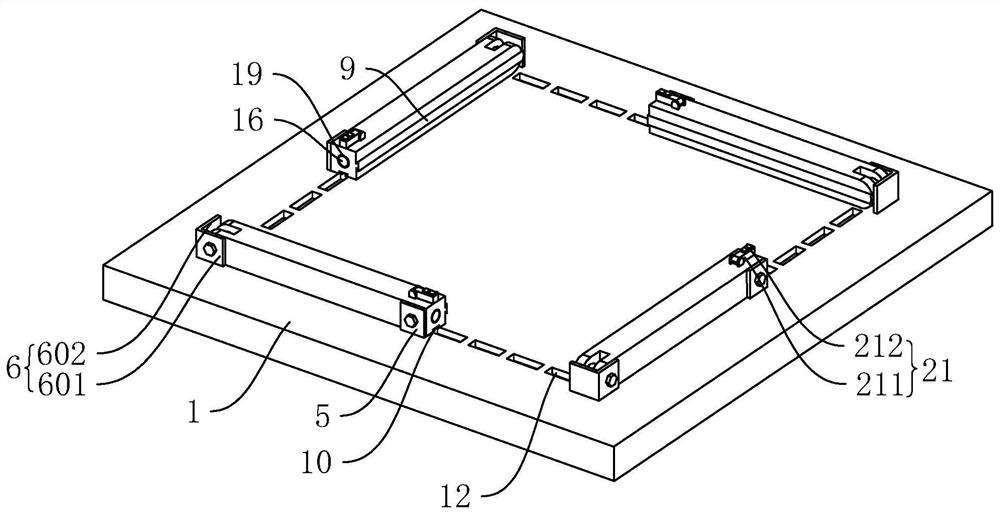

[0045] refer to figure 2, the top of the bottom plate 1 is fixedly connected with four fixed plates 5, and the four fixed plates 5 are set in one-to-one correspondence with the positions of the columns 3. When each column 3 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com