Embedded steel bar anchoring method for tying wall top of infilled wall and beam or plate

An anchoring method and wall filling technology, which is applied in the processing of walls, building materials, building components, etc., can solve problems such as easy confusion in construction, lack of earthquake resistance, and insufficient rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but are not intended to limit the protection scope of the present invention.

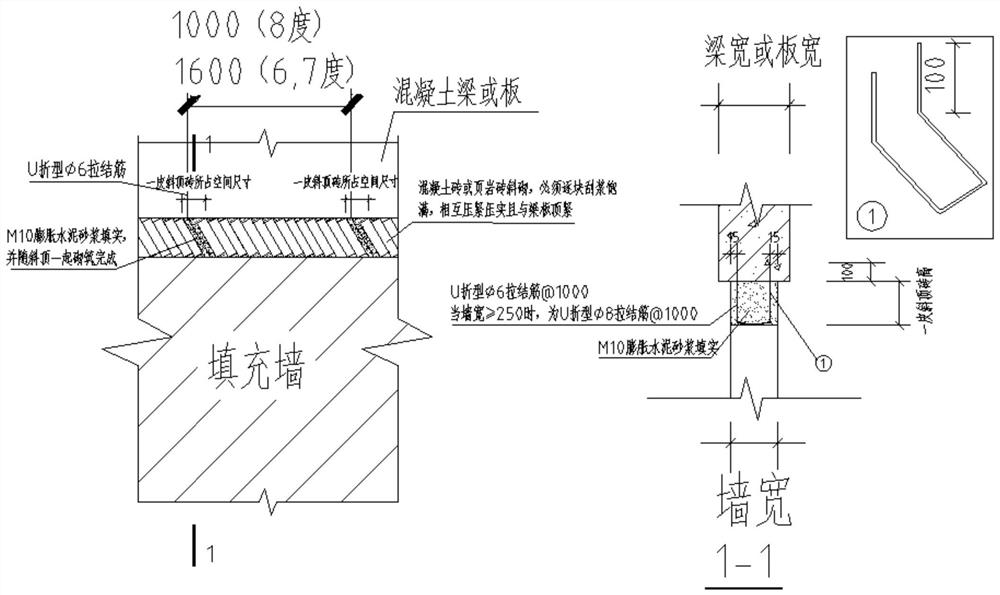

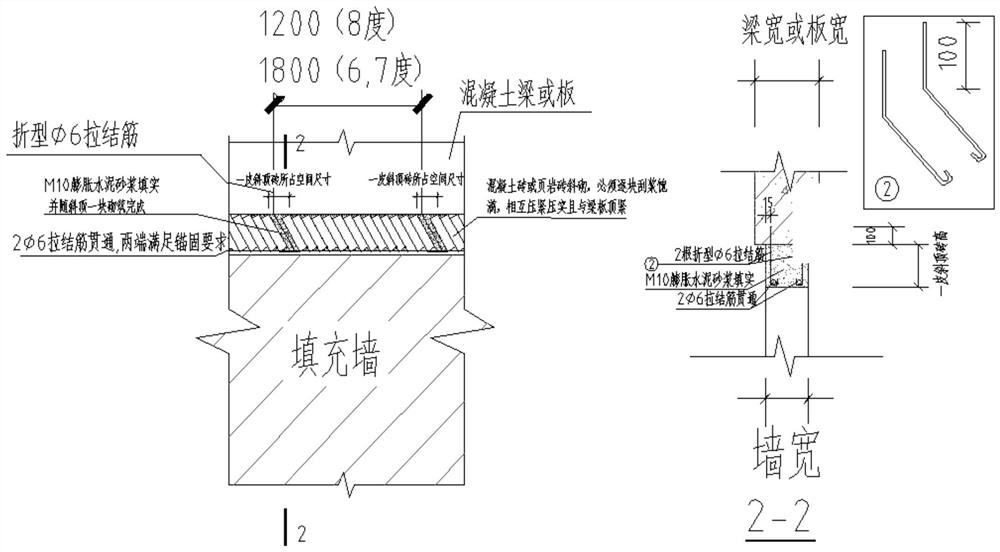

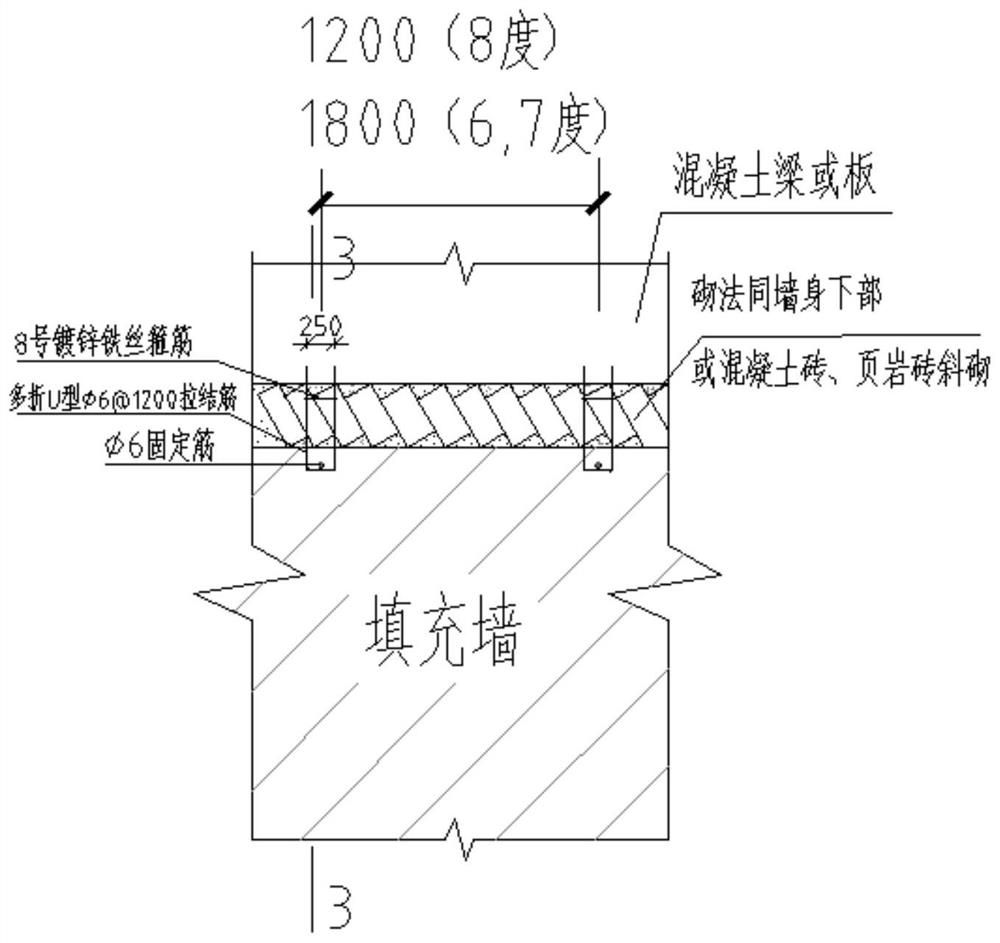

[0052] A reinforcement anchoring method for filling the top of the wall and a beam or slab in this embodiment, including the first reinforcement method, the second reinforcement method, the first remedial measure, the second remedial measure and the third remedial measure measure.

[0053] Among them, in the first reinforcement method and the second reinforcement method, the anchor reinforcement planted on the beam or slab is built together with the inclined roof bricks, and the scraped grout is fully compacted and compacted in the mortar to form a whole to form a new building together. The top of the wall, so that the tie can meet the seismic construction requirements of the top of the wall when the wall length is greater than 5m; the first remedial measure, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com