Calibration system and method applied to ultrasonic gas meter

A technology for calibrating systems and gas meters, applied in testing/calibrating devices, measuring devices, instruments, etc., can solve problems such as time-consuming, easily lost pulses, high cost, etc., to improve accuracy, reduce time-consuming, and avoid lost errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

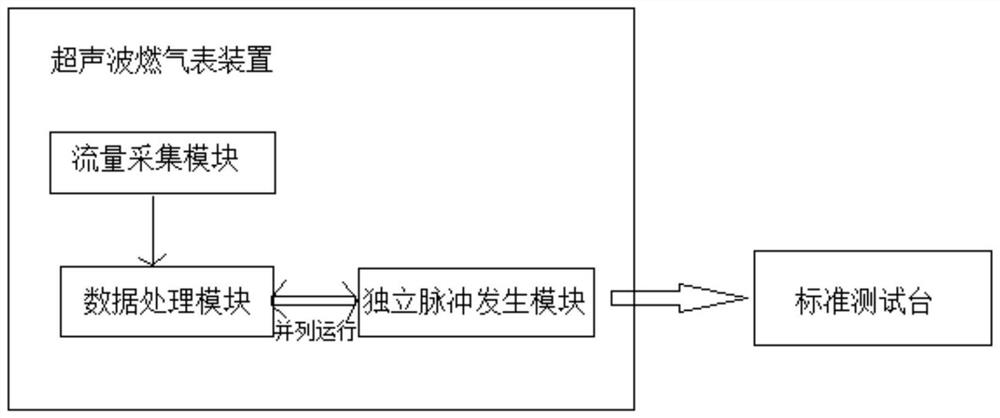

[0050] This embodiment provides a calibration system applied to an ultrasonic gas meter, including a standard test bench and an ultrasonic gas meter device. The ultrasonic gas meter device includes: a flow acquisition module, a data processing module and an independent pulse generation module;

[0051] The flow collection module collects gas flow rate data in the metering pipeline every t seconds;

[0052] The data processing module formulates a pulse sending strategy according to the current gas flow rate data and the current gas flow level, and at the same time, the independent pulse generating module sends pulses to the standard test bench according to the pulse sending strategy, and the independent pulse generating module and the data processing module run in parallel;

[0053] The standard test bench calculates the measured flow data based on all pulses received during the calibration measurement time. The standard test bench compares the measured flow data with the standa...

Embodiment 2

[0072] A calibration method applied to an ultrasonic gas meter is applied to a calibration system applied to an ultrasonic gas meter in Embodiment 1, comprising the following steps;

[0073] During the calibration measurement time, the gas flow rate data in the metering pipeline is collected every t seconds;

[0074] According to the current gas flow rate data and the current gas flow level, the pulse sending strategy is formulated, and the pulse is sent to the standard test bench according to the pulse sending strategy;

[0075] Calculate the measured flow data based on all pulses received within the calibration measurement time, compare the measured flow data with the standard flow data to obtain the error value of the ultrasonic gas meter, and calibrate the ultrasonic gas meter.

[0076] The standard test bench judges whether the error value of the ultrasonic gas meter is within the preset range,

[0077] If not, send the corresponding standard flow data to the ultrasonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com