Power cable with good heat dissipation performance

A technology for power cables and heat dissipation performance, applied in the field of power cables, can solve the problems of reducing cable service life, cable failure, cable damage, etc., to ensure stable operation and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

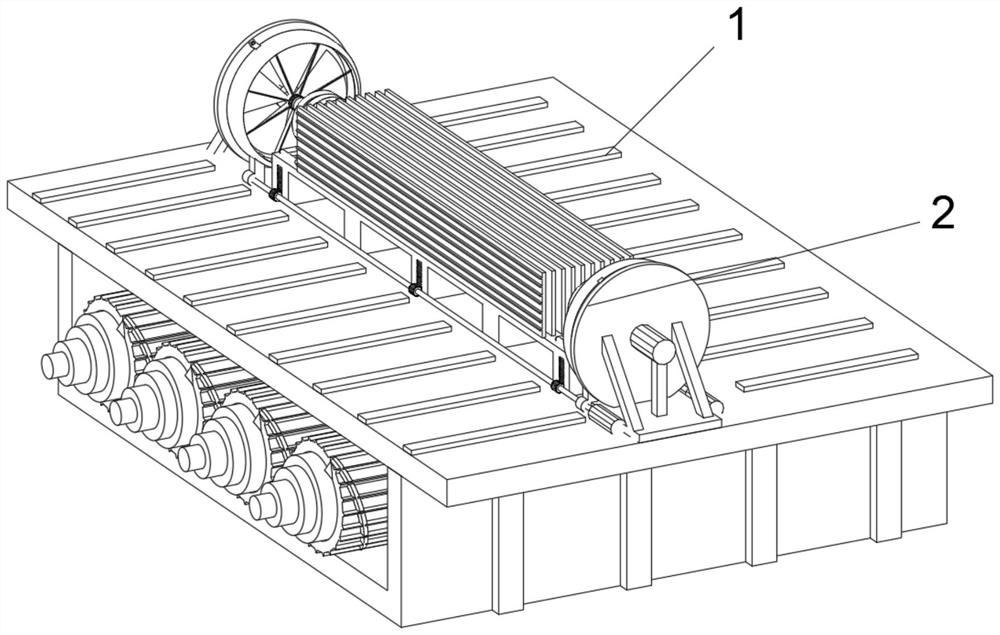

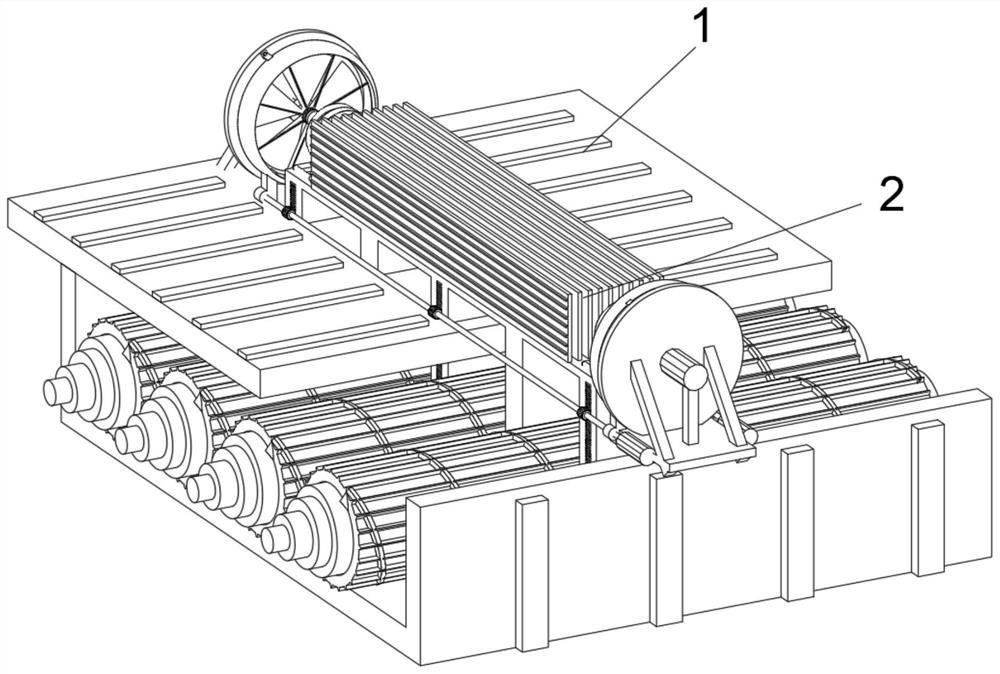

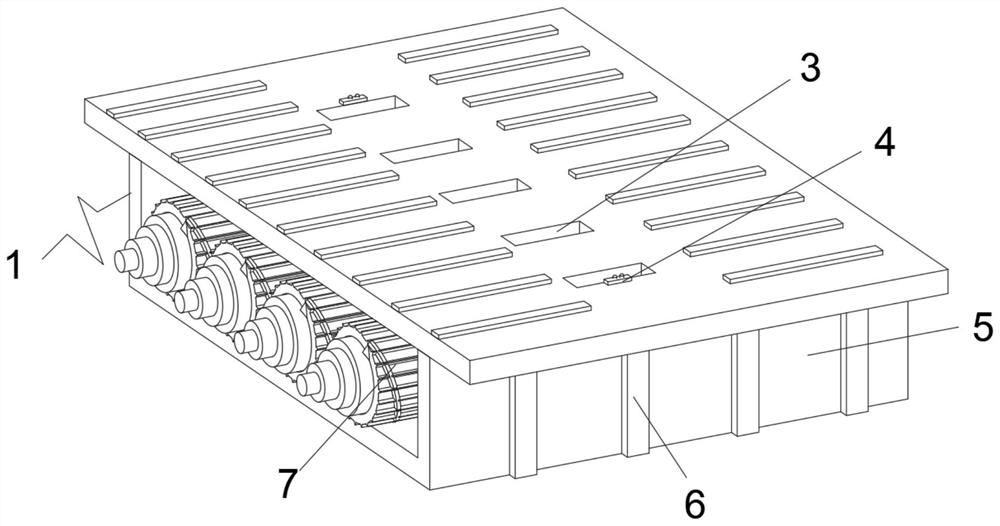

[0029] see Figure 1-3 , an embodiment provided by the present invention: a power cable with good heat dissipation performance, including a power cable main body 1 and a heat dissipation device 2, the heat dissipation device 2 is slidably inserted on the top surface of the power cable main body 1, and the inside of the power cable main body 1 A bridge frame 5 is fixedly installed, and the outer peripheral surface of the bridge frame 5 is evenly fixedly connected with a heat dissipation plate 6, and the inside of the power cable main body 1 is evenly connected with a cable 7, and the top surface of the bridge frame 5 is uniformly provided with an insertion slot 3, and the top surface of the bridge frame 5 Control buttons 4 are fixedly installed on both sides of the surface and on the side edges of the insertion slot 3;

[0030] see Figure 4 , the interior of the cable 7 is fixedly installed with a metal wire 10, the outer surface of the metal wire 10 is fixedly sleeved with a...

Embodiment 2

[0047] On the basis of Example 1, such as Figure 10 As shown, the sides of the heat dissipation assembly 24 are evenly fixedly connected with heat dissipation tooth plates 30, the bottom surface of the heat dissipation assembly 24 is uniformly provided with heat dissipation grooves 32, the two ends of the heat dissipation assembly 24 are fixedly connected with sealing plates 31, and the top surface of the heat dissipation assembly 24 is evenly opened. There is a storage tank 33, and the inside of the storage tank 33 is filled with condensate.

[0048] When this embodiment is implemented, the storage tank 33 can collect the condensate, so that the fan blade 15 can run to purge and dissipate heat from the cooling assembly 24. When the condensate is blown by the wind, it will quickly cool down, and the condensate will The heat dissipation assembly 24 is absorbed inside the storage tank 33, thereby increasing the cooling speed of the heat dissipation assembly 24. When the heat di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com