Feeding trough capable of being cleaned in turnover mode for animal husbandry

A flipping, animal husbandry technology, applied in the field of feeding tanks, can solve the problems of low practicability and difficult cleaning, and achieve the effect of reducing labor intensity and realizing automatic opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

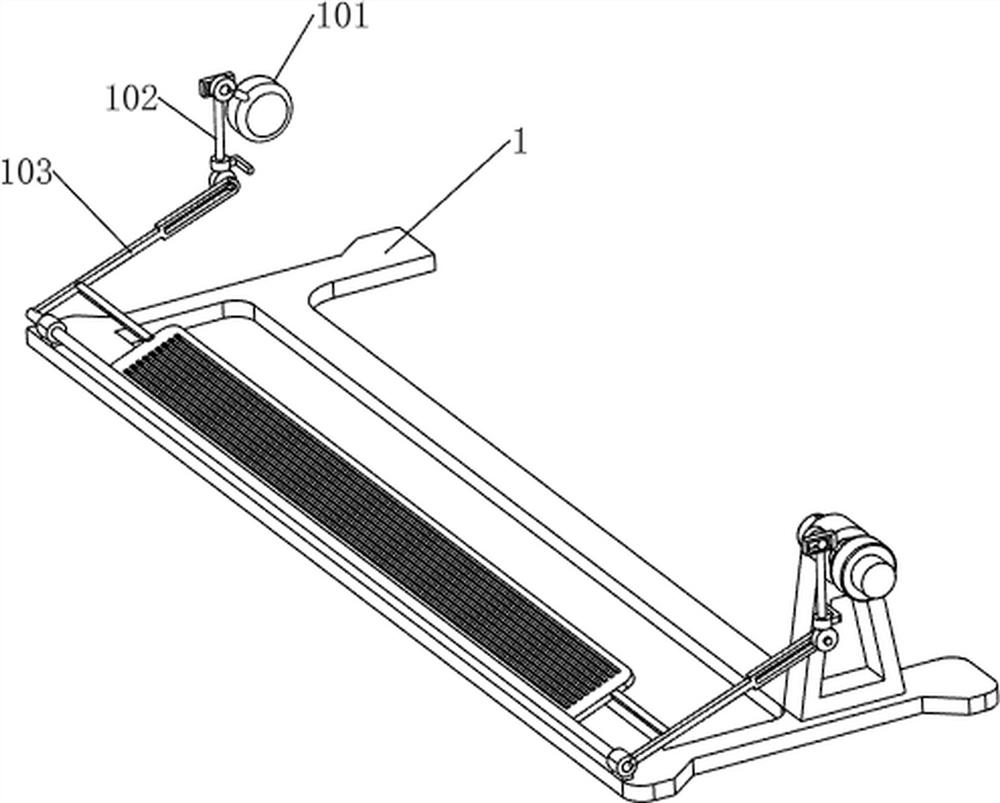

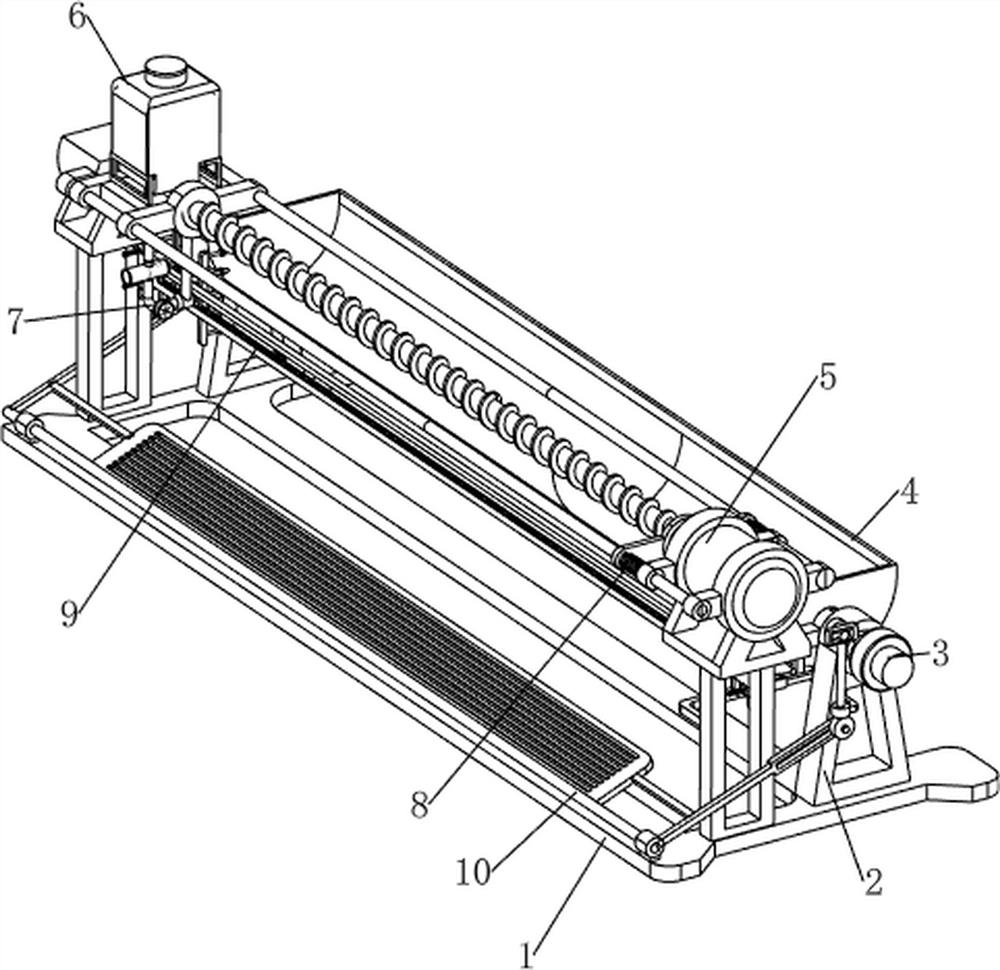

[0059] A feeding tank that can be flipped and cleaned in animal husbandry, such as Figure 1-5 As shown, it includes a base 1, a supporting platform 2, a rotating shaft 3, a breeding tank 4, a rotating mechanism 5, a storage mechanism 6 and a cleaning mechanism 7. The right side of the base 1 is symmetrically provided with a supporting platform 2, and the upper part of the supporting platform 2 is of a rotating type. A rotating shaft 3 is connected, and a rectangular hole is opened on the rotating shaft 3 on the front side. A breeding tank 4 is connected between the inner sides of the rotating shaft 3. A rotating mechanism 5 is provided on the left side of the base 1, and a storage mechanism 6 is arranged on the rotating mechanism 5 parts. , The storage mechanism 6 is provided with a cleaning mechanism 7.

[0060] When people need to feed livestock, they can use this device. People manually feed the feed in the feeding tank 4 for the livestock to eat. After eating, people put ...

Embodiment 2

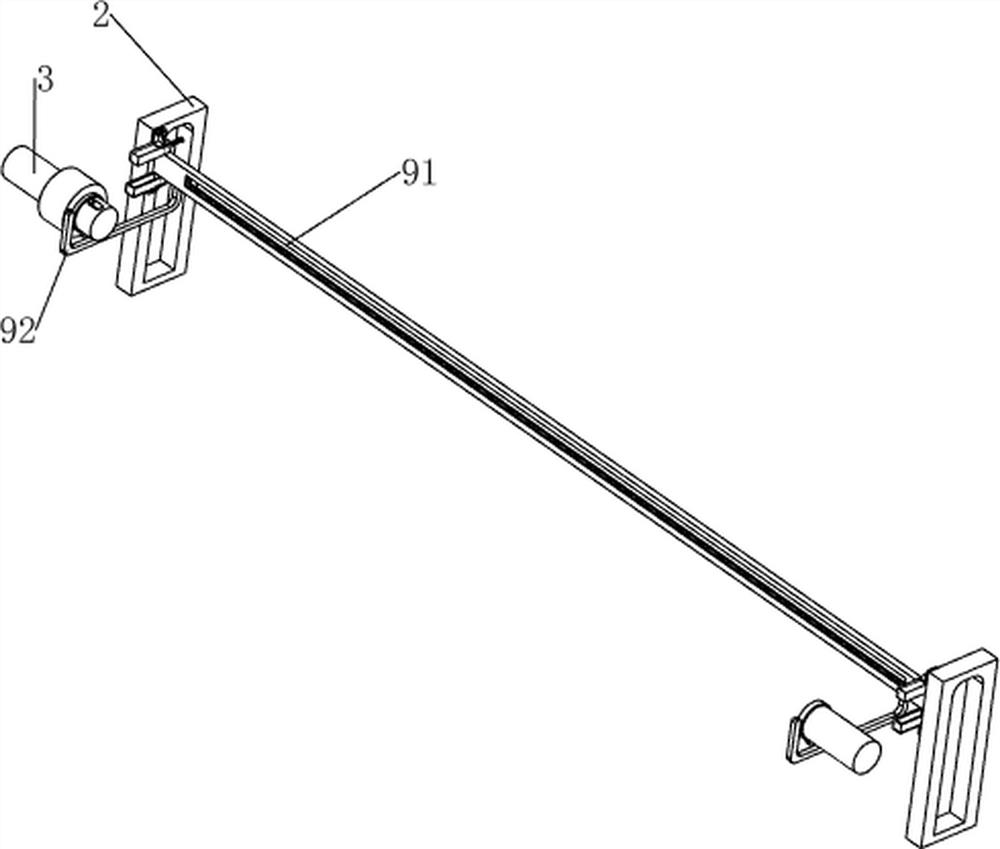

[0066] On the basis of Example 1, such as Figure 6-10 As shown, a clamping mechanism 8 is also included, and the clamping mechanism 8 includes a second bracket 81, a fixed frame 82, a first compression spring 83, a clamp rod 84 and a second compression spring 85, and the first bracket 51 on the front side is left A second bracket 81 is provided on the side, and a fixed frame 82 is provided on the upper right side of the second bracket 81. A toggle block is slidably connected between the front sides of the slide bar 54, and a toggle block is connected with the first bracket 51 on the front side. 2 first compression springs 83, the fixed frame 82 is slidingly connected with a clamping rod 84, the clamping rod 84 is in contact with the rotating shaft 3 on the front side, and the second compression spring is connected between the right side of the clamping rod 84 and the left side of the fixed frame 82 Spring 85.

[0067] People manually rotate the rotating shaft 3, and when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com