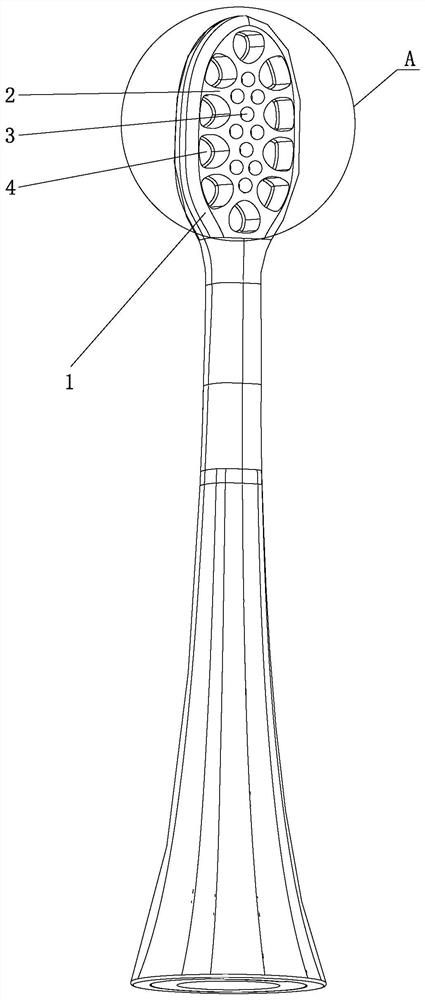

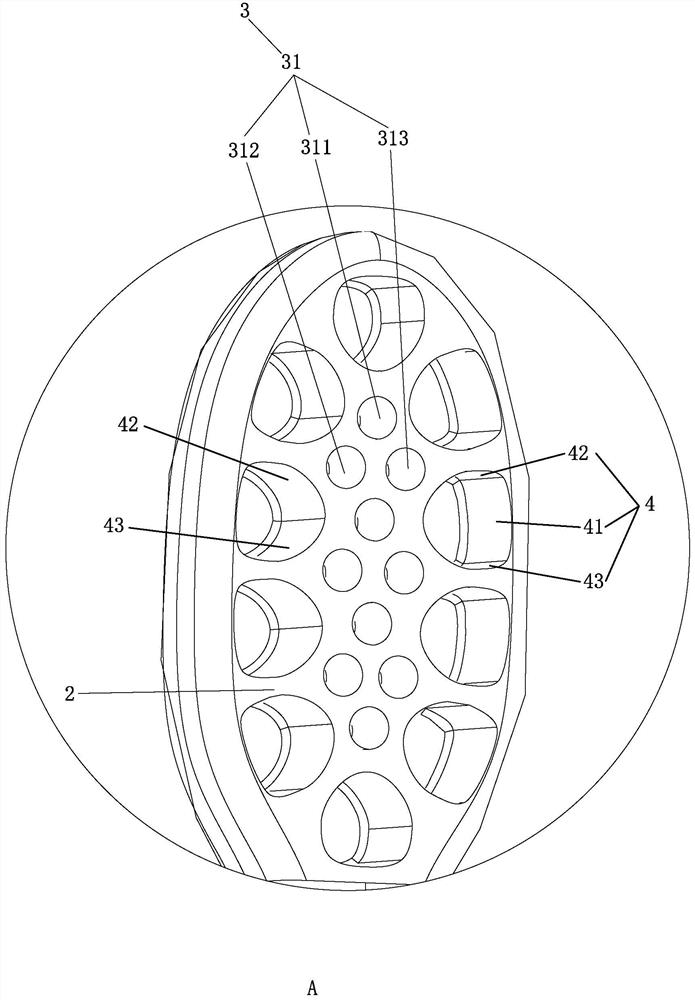

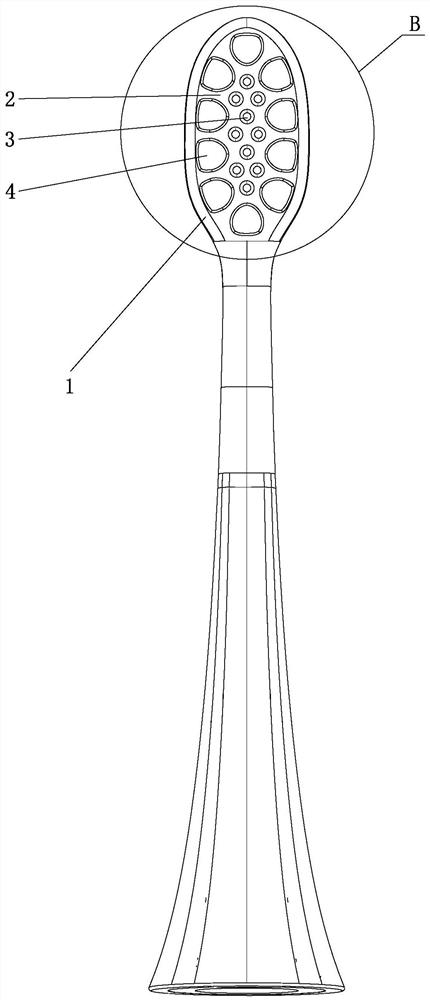

Electric toothbrush head and manufacturing method thereof

An electric toothbrush and its production method are applied in the fields of dentistry, cleaning teeth, medical science, etc., and can solve problems such as sensitivity, hard bristles, and consumers' resistance to using electric toothbrushes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0063] Implementation case: Plastic injection bristles are injection molded on the peripheral hair planting holes. The rubber injection hairs have a double peak structure, the length of the single peak is 10mm, and the length of the bristles is 11mm. .

[0064] Comparison case 1-electric toothbrush heads with nylon round bristles common in the market;

[0065] Comparative case 2 - large-hole beam electric toothbrush heads with AFT technology on the market;

[0066] Comparison method: 10 people were randomly selected to evaluate the interdental cleaning power and gum pain in the above-mentioned implementation cases; the evaluation method of interdental cleaning power was in the form of scoring, and the difference between the scores of each grade was 5 points, and the total score was 100 points. The final results are calculated by means of average scores; the pain of the gums when brushing teeth is evaluated by the pain level, and the evaluation method is scored. The difference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com