Gas-liquid separation device based on chemical production

A gas-liquid separation device, a technology for chemical production, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of polluting the environment and separation effect, unable to achieve automatic discharge, low practicability, etc., and achieve stable use. , improve practicality and flexibility, facilitate the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] as attached figure 1 to attach Figure 7 Shown:

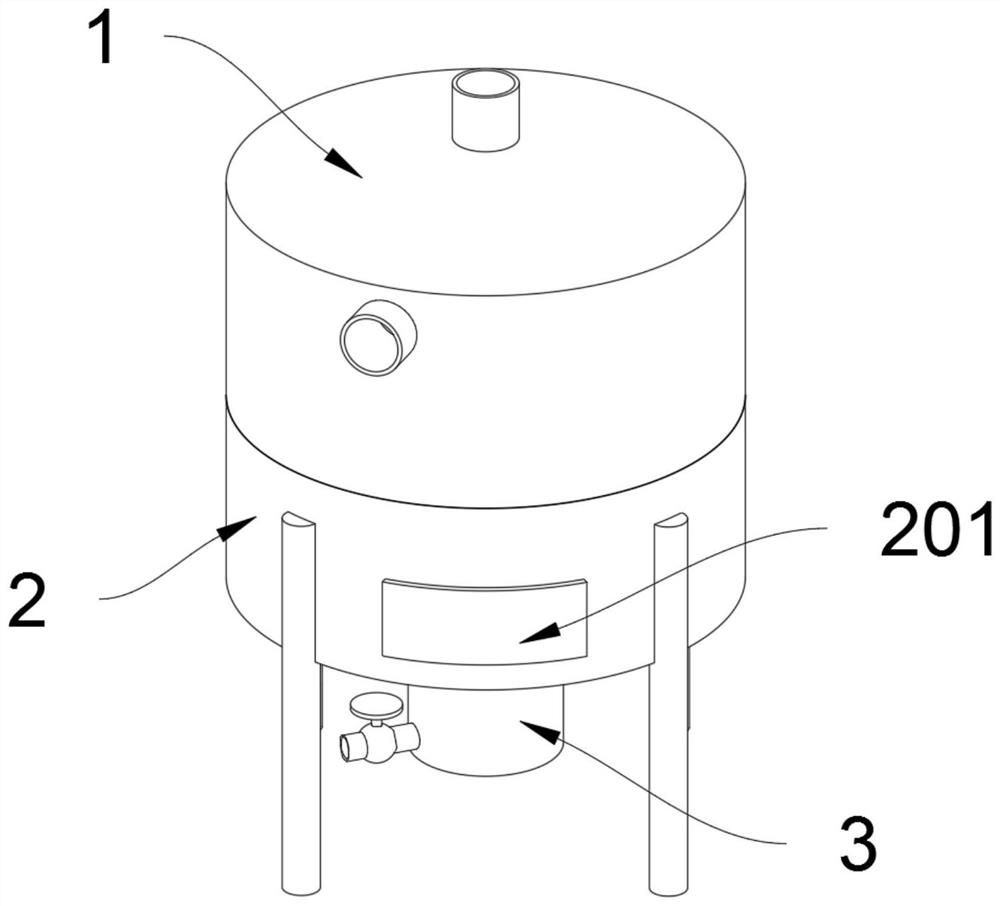

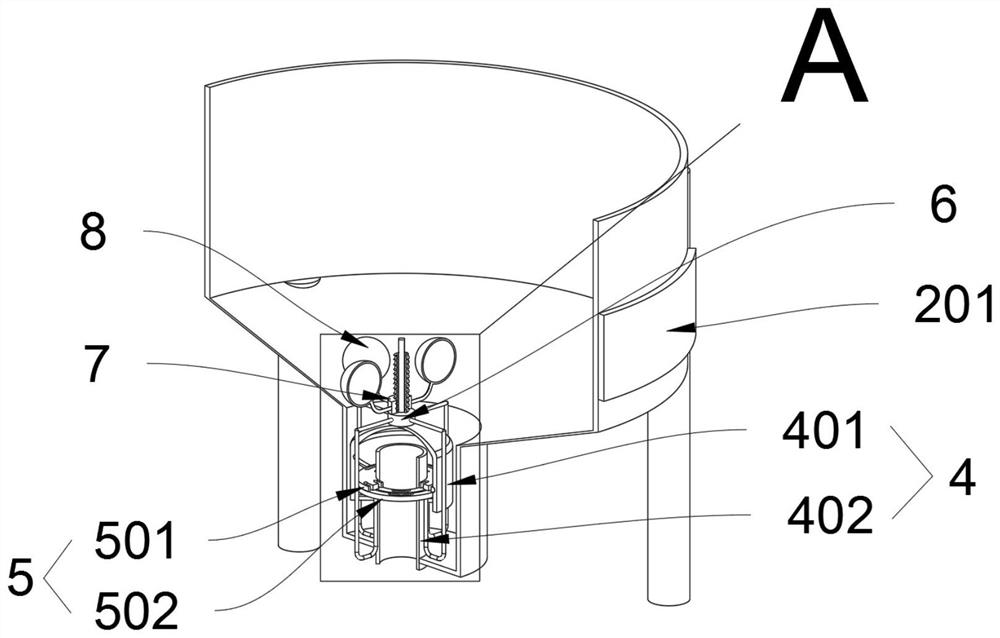

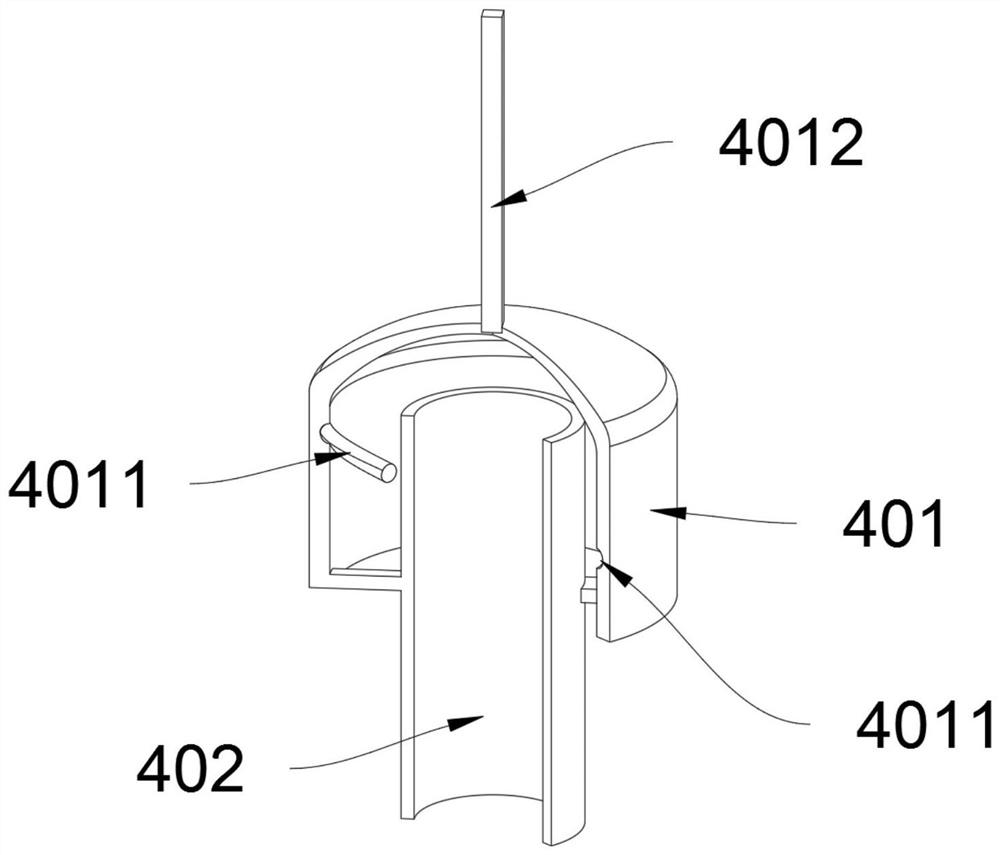

[0034]The present invention provides a gas-liquid separation device based on chemical production, including a gas-liquid separator 1, a drainage cover tube 3, a siphon drainage cover 4, a gas blocking mechanism 5, an installation block 6, a floating ball control block 7 and a hollow floating ball 8. The bottom of the gas-liquid separator 1 is fixedly connected with a liquid collection box 2, and the side and top of the gas-liquid separator 1 are fixedly connected with an intake pipe and an exhaust pipe respectively; the side of the liquid collection box 2 is provided with an inspection sealing door 201 The drain cover pipe 3 is fixedly connected to the bottom of the liquid collection tank 2, and the side of the drain cover pipe 3 is fixedly connected with a main drain valve; the siphon drain cover 4 is composed of a siphon cover 401 and a drain main pipe 402, and the siphon cover 401 is fixedly connected Outside the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com