Technical method for longitudinal dimension amplification of assembling of aluminum alloy chassis frame

A process method, aluminum alloy technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as unreasonable process volume, out-of-tolerance chassis size, etc., to ensure rationality and accuracy, and reasonable data chain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, taking the underframe of a certain aluminum alloy rail vehicle currently used in China as an example.

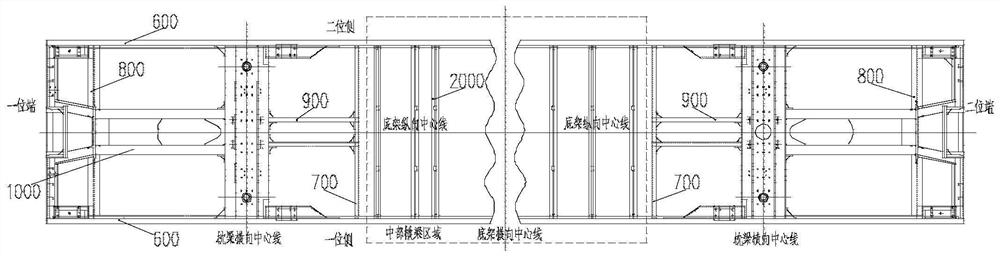

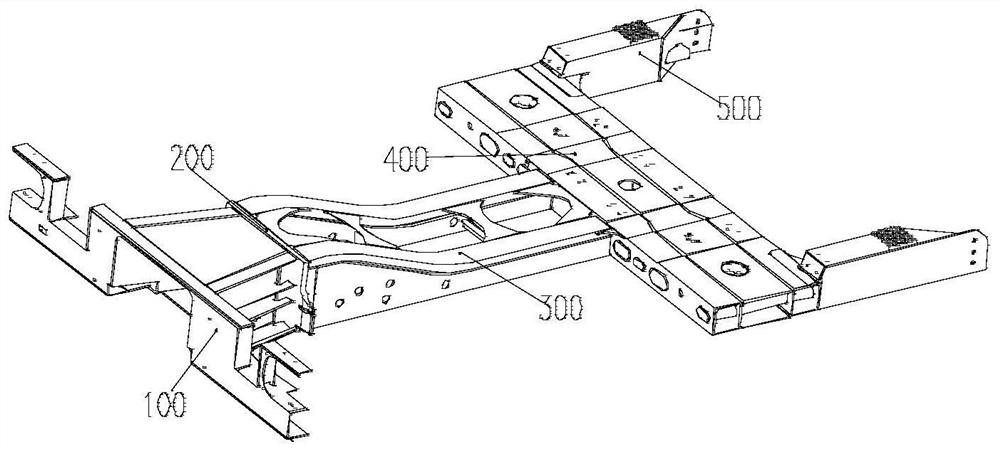

[0027] like figure 1 as shown,

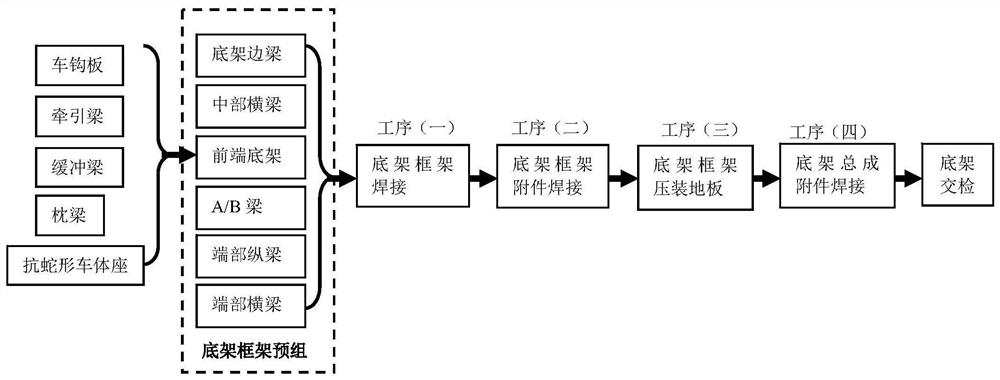

[0028] Generally speaking, the longitudinal dimensions of the front-end underframe 1000, the length of the side beams, the pre-assembled longitudinal dimensions of the underframe frame, the post-process welding shrinkage deformation, the technical conditions of the car body manufacturing, and the welding standards, etc., will all affect or restrict The longitudinal length dimension of the chassis for inspection. However, the large amount of longitudinal dimension during the pre-assembly of the chassis frame plays a pivotal role, which not only affects the smooth assembly of the front chassis, but also directly determines the product inspection after the chassis is completed. The underframe frame is assembled and welded by a variety of profiles and the front end underframe. On the one hand, due to the influence of frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com