Engine oil recycling and cleaning device for numerical control machine tool

A cleaning device, a technology for CNC machine tools, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., to solve problems such as oil waste, inability to recycle, and insufficient oil treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

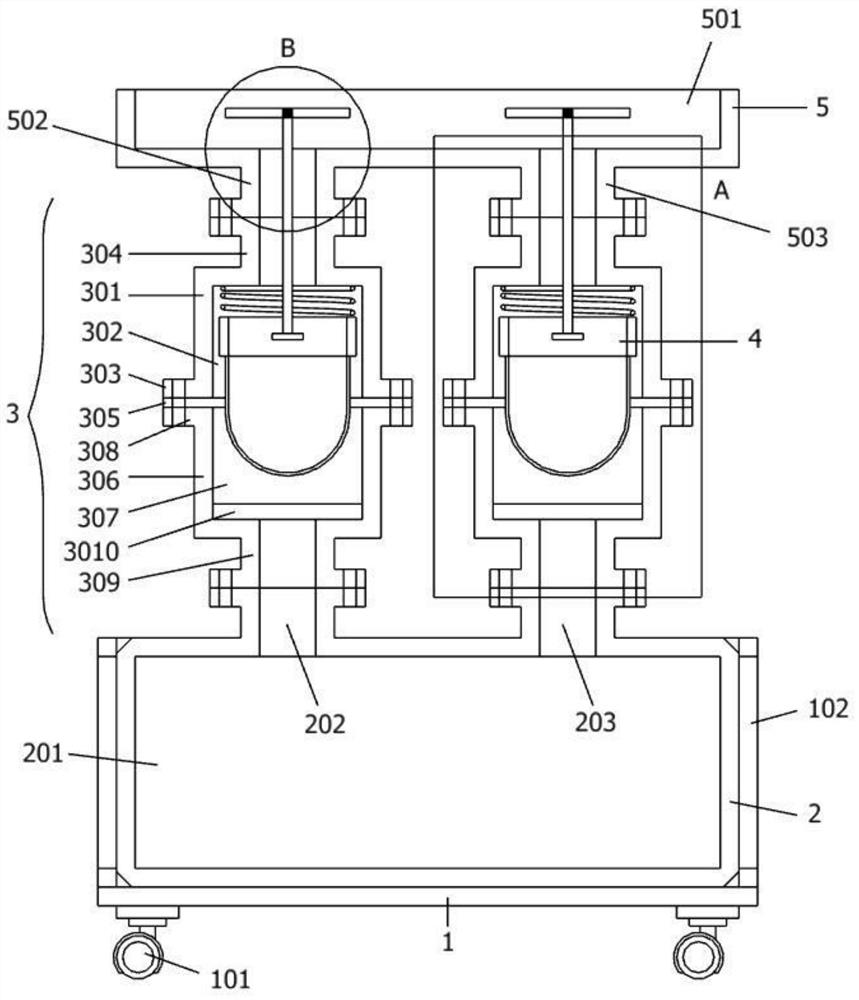

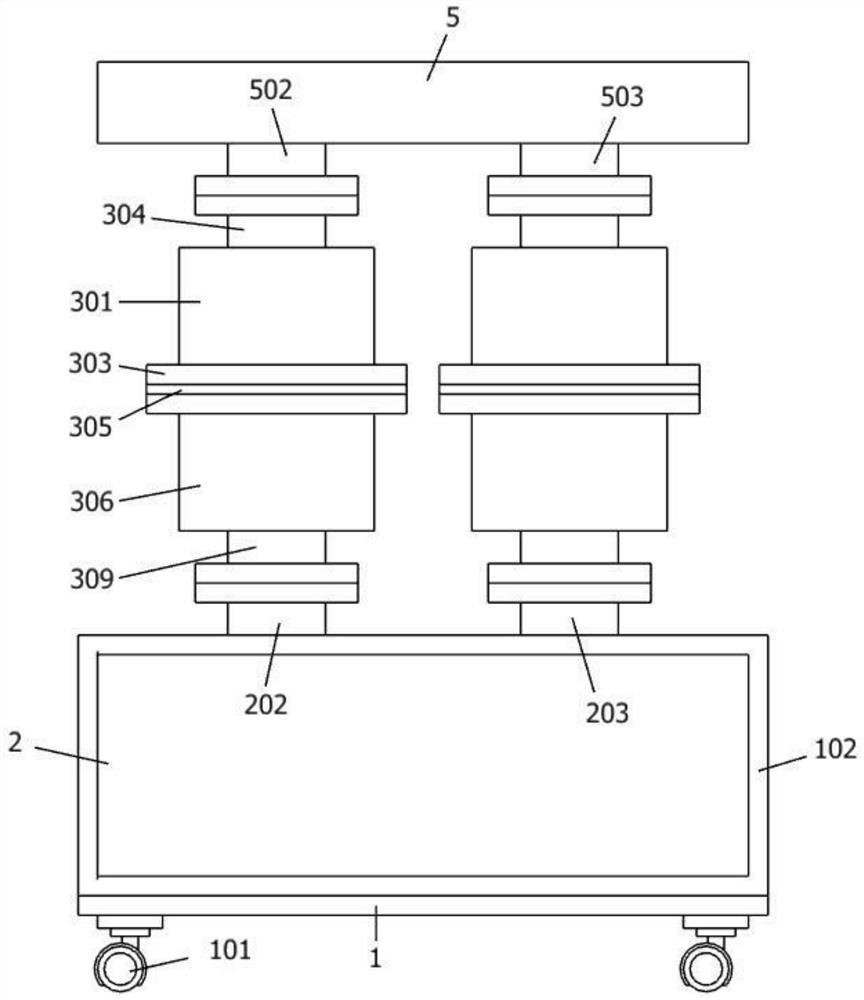

[0031] as attached figure 1 to attach Image 6 Shown:

[0032]The invention provides an engine oil recovery and cleaning device for a numerically controlled machine tool, comprising: a bearing base plate 1, an oil recovery shell 2 is placed on the top surface of the load base plate 1, and two sets of first flanges are sealed and connected to the top of the oil recovery shell 2 Two filter residue mechanisms 3; two sets of second filter residue mechanisms 3 are fixedly installed with a set of first filter residue mechanisms 4, and the tops of the two groups of second filter residue mechanisms 3 are jointly sealed with an oil receiving housing 5; the first filter residue mechanisms 4 include Horizontal welding support plate 402, support column 405, stud 406 and circular block 407, a horizontal welding support plate 402 is welded on the inner peripheral surface of the reciprocating cylinder 401, and a support column is welded at the center of the top surface of the transverse wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com