A single-track adjustable jaw production line

An adjustable, production line technology, applied in the direction of chucks, manufacturing tools, manipulators, etc., can solve the problems of parts scratches and low work efficiency, and achieve the effect of improving work efficiency and increasing the range of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

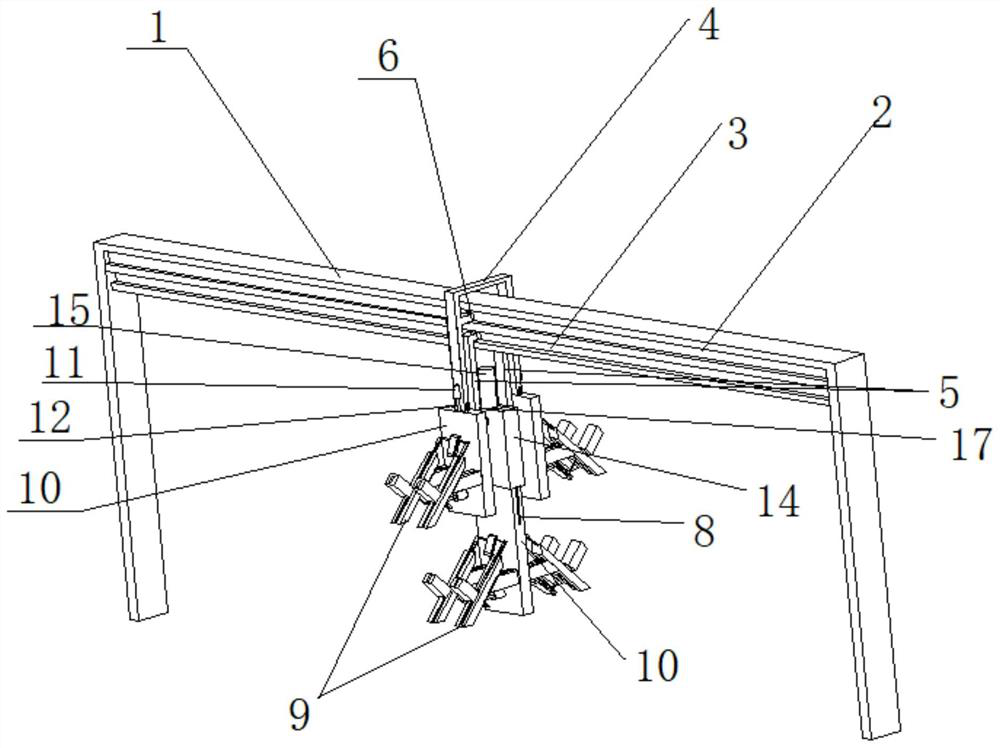

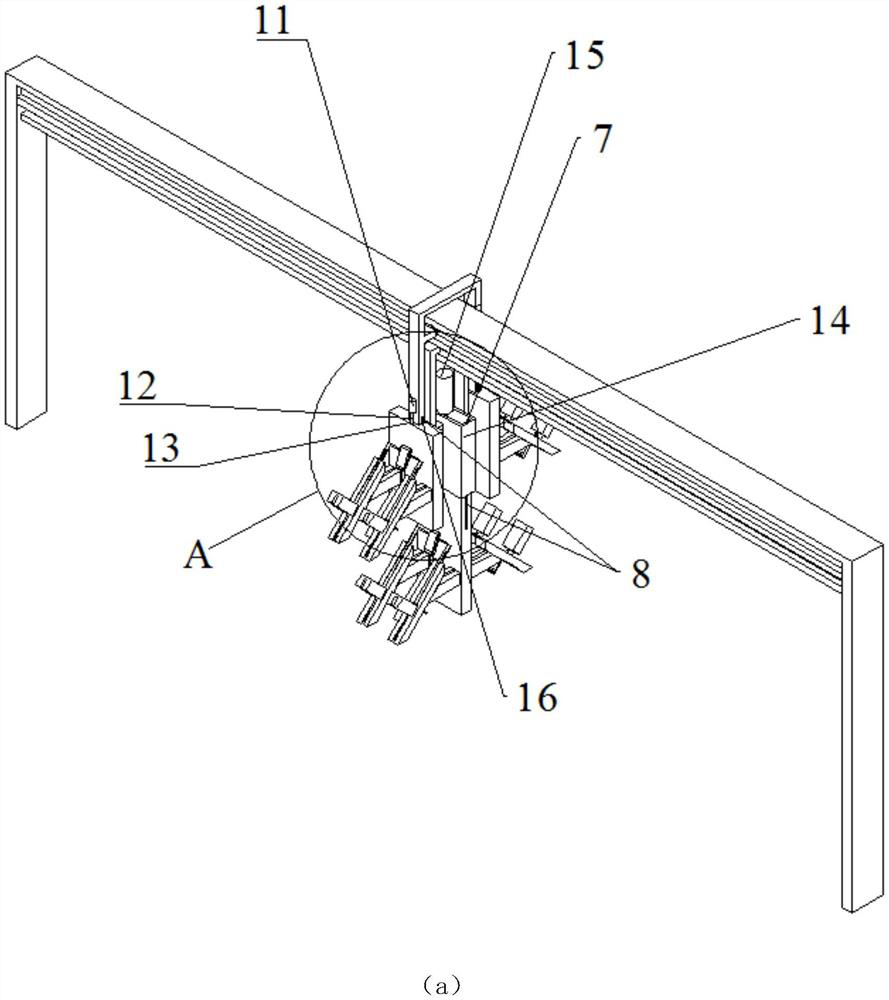

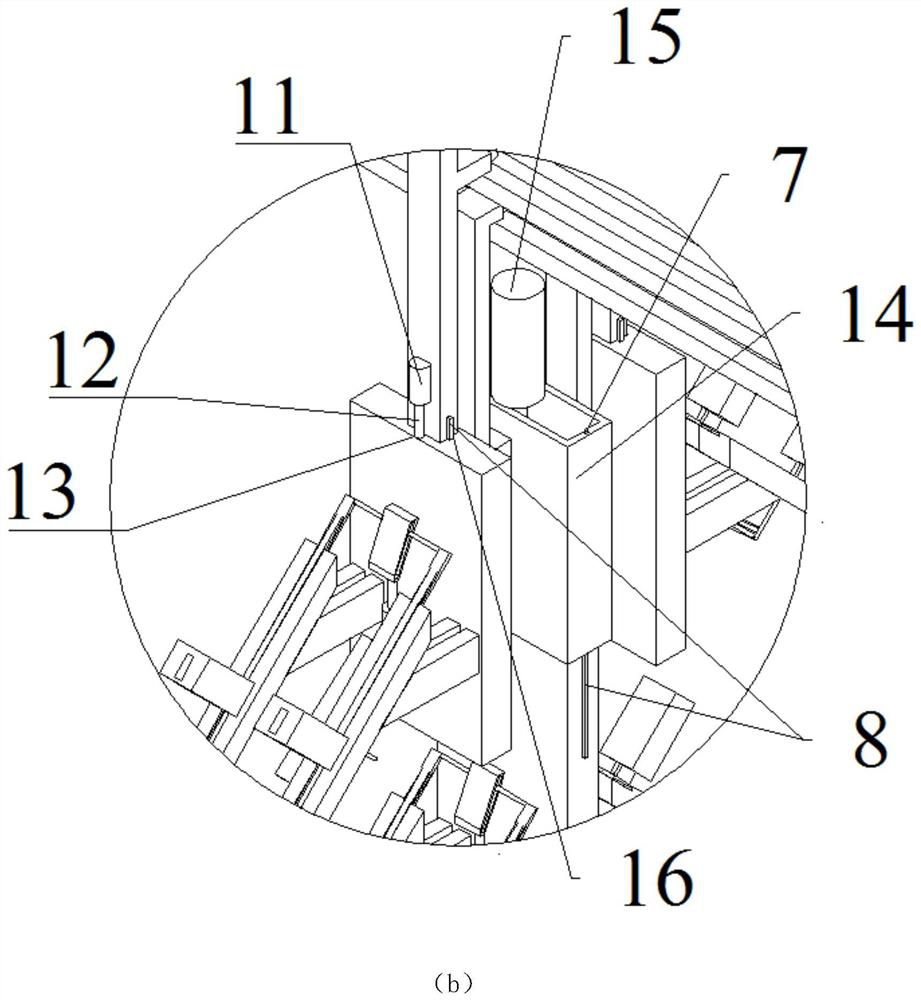

[0035] like Figure 1-5 As shown, a single-track adjustable clamping jaw production line includes a girder 1, and a first slideway 2 and a second slideway 3 are sequentially arranged on the girder 1 from top to bottom, and the first slideway 2 and the second slideway 3 are arranged on The first sliding frame 4 and the second sliding frame 5 are respectively matched with the pulley 6 .

[0036] Vertical guide rails 8 are respectively provided on the two side walls of the front and rear vertical arms of the first sliding frame 4, and the jaw columns 10 of the adjustable jaws 9 are arranged in cooperation with each vertical arm. The guide rail 8 slides with the sliding groove one 16, and each vertical arm is provided with a motor 11. The motor 11 is driven by the lead screw 12 and the lead screw hole 13 located in the adjacent jaw column 10 to drive the corresponding clamp. The jaw post 10 slides vertically relative to the upright arm so as to adjust the height of the adjustable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com