Small-section tunnel slagging-off system

A small-section and tunnel technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of lack of a complete and efficient slag discharge system in small-section tunnels, equipment that cannot perform effective operations, and small slag trucks that cannot turn around. Small footprint, reduced volume, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

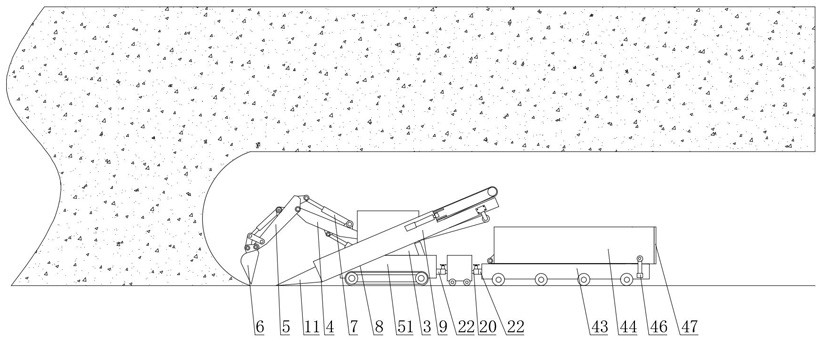

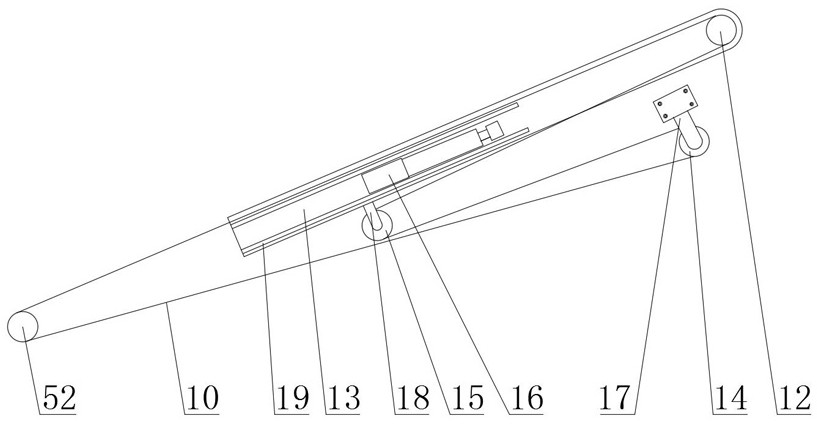

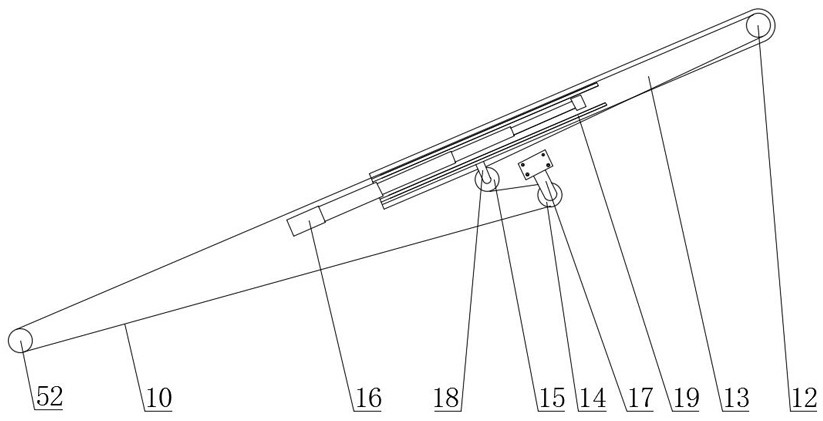

[0025]Referring to the above-mentioned accompanying drawings, the small-section tunnel slag removal system provided by the present invention is characterized in that it includes a slag remover, a long slag loader and a slag truck 1, and the slag remover and the long slag loader A driving car 2 is detachably arranged between them. The slag removal machine includes a car body 51 and a control room 3 arranged on the car body 51. The front end of the car body 51 is movably connected with a first arm 4, and the other end of the first arm 4 is A second arm 5 is movably connected, and the other end of the second arm 5 is movably connected with a slag removing head 6. The first arm 4, the second arm 5 and the slag removing head 6 are all driven by a first hydraulic cylinder 7. A conveying mechanism 8 is movable on the body 51, and the conveying mechanism 8 can rotate on the car body 51 through the second hydraulic cylinder. The conveying mechanism 8 includes a housing 9, a motor, a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com