A sedimentation tank and sedimentation method for mine cinder water

A sedimentation tank and cinder technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of heavy labor load and incomplete cleaning, and achieve the effect of simple installation and layout, simple structure, and avoidance of clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

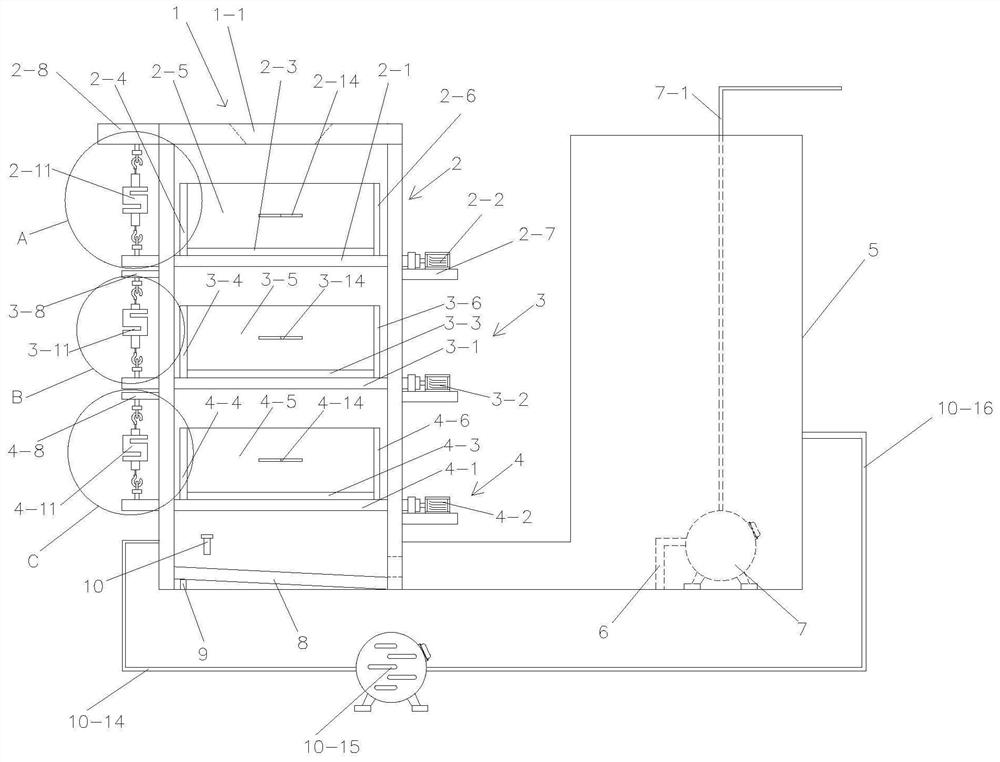

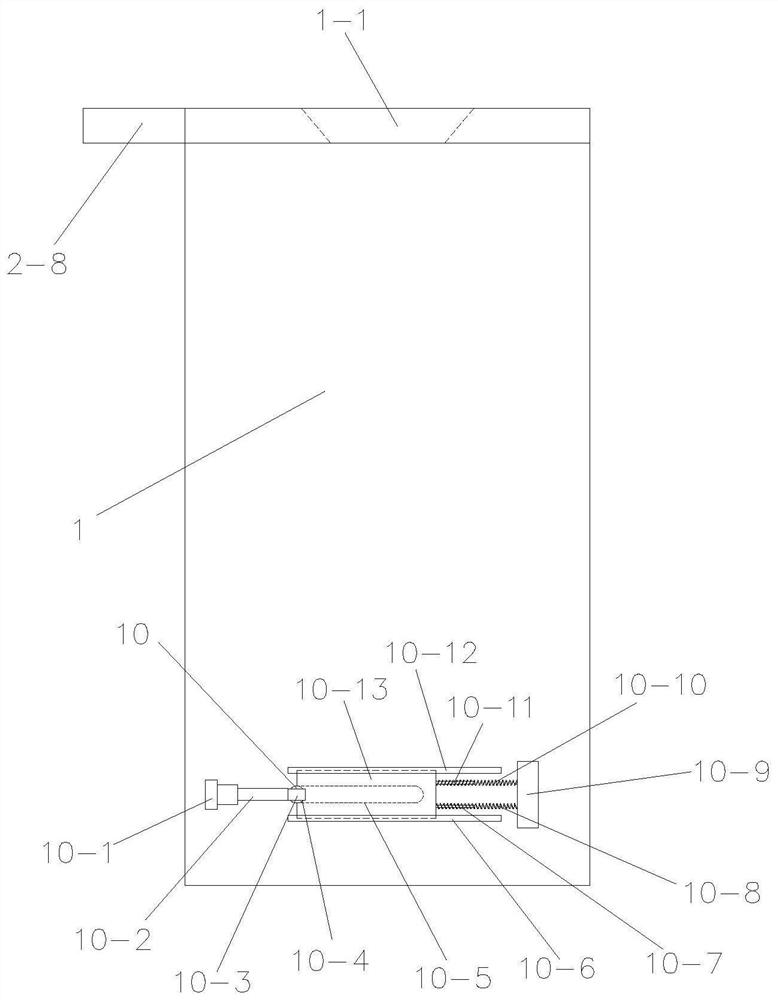

[0097] like figure 1 and figure 2 The sedimentation tank for mine cinder water shown includes a filter box and a drainage mechanism connected with the filter box. The filter box includes a box body 1 and a first set of tanks arranged in the box body 1 and arranged in sequence from top to bottom. A filter mechanism, a second filter mechanism and a third filter mechanism, the bottom of the box 1 is provided with an inclined part;

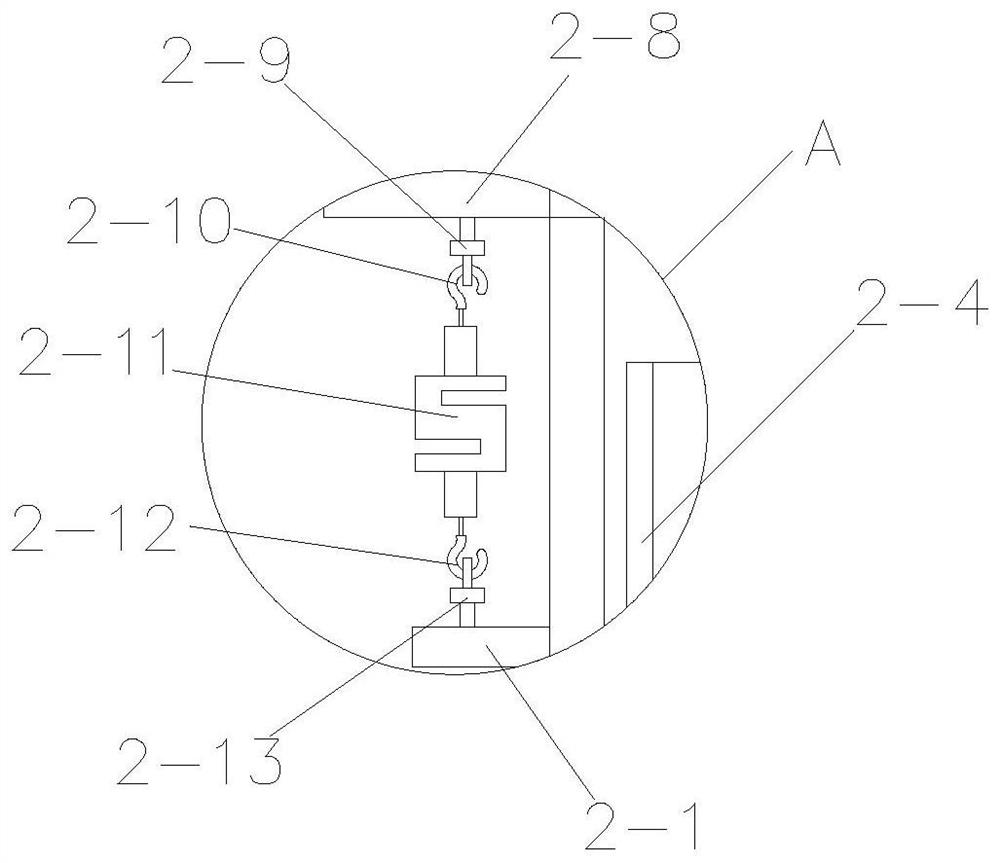

[0098] The first filtering mechanism 2 includes a first rotating shaft 2-1, a first filtering component arranged on the first rotating shaft 2-1, and a first motor 2- 2. The second filtering mechanism 3 includes a second rotating shaft 3-1, a second filtering component arranged on the second rotating shaft 3-1, and a second motor connected to the second rotating shaft 3-1 in transmission 3-2. The third filtering mechanism 4 includes a third rotating shaft 4-1, a third filtering component arranged on the third rotating shaft 4-1, and a first rotatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com