Water circulation cooling device for storage battery colloid production equipment

A technology for water circulation cooling and production equipment, which is applied in cooling fluid circulation devices, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of temperature increase, reduce cooling efficiency, etc., to improve heat exchange efficiency and improve service time. and the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

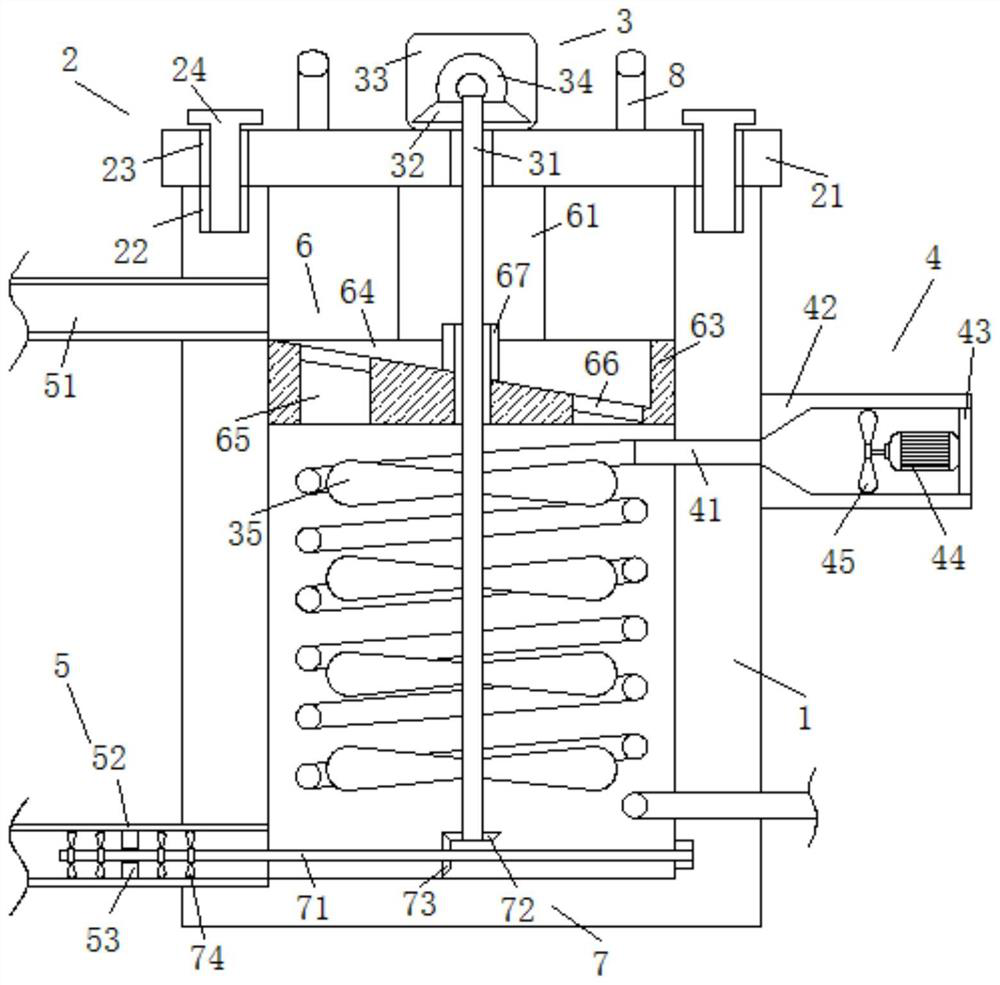

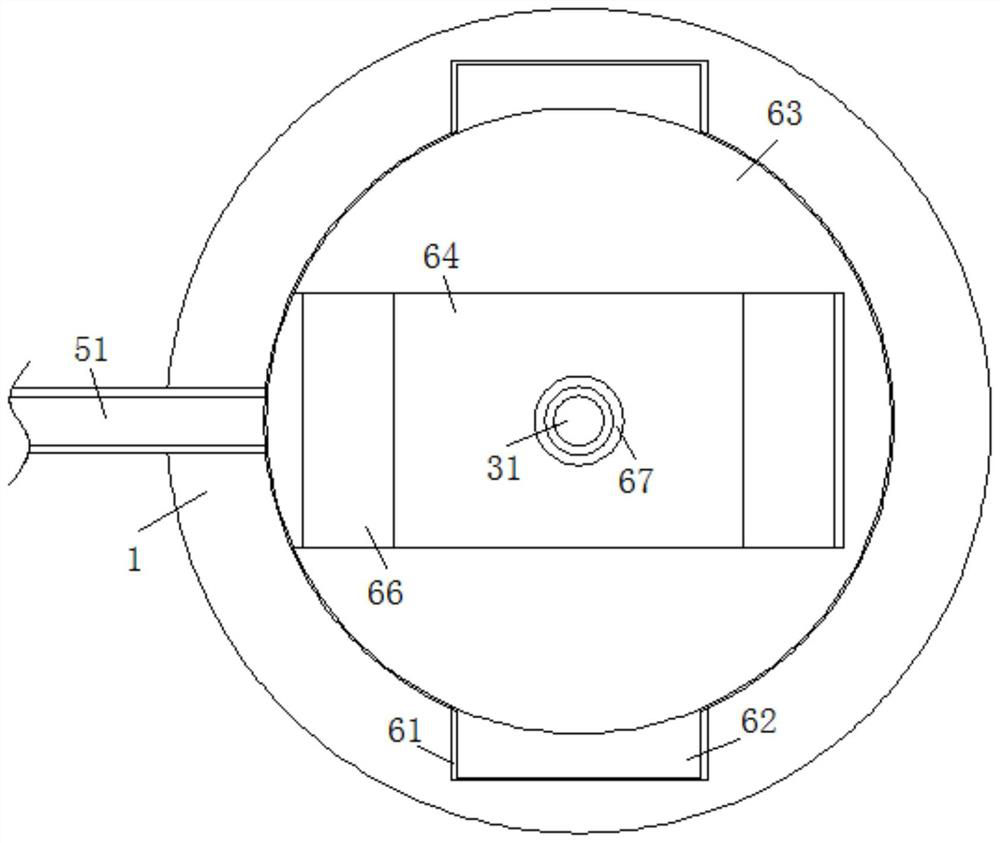

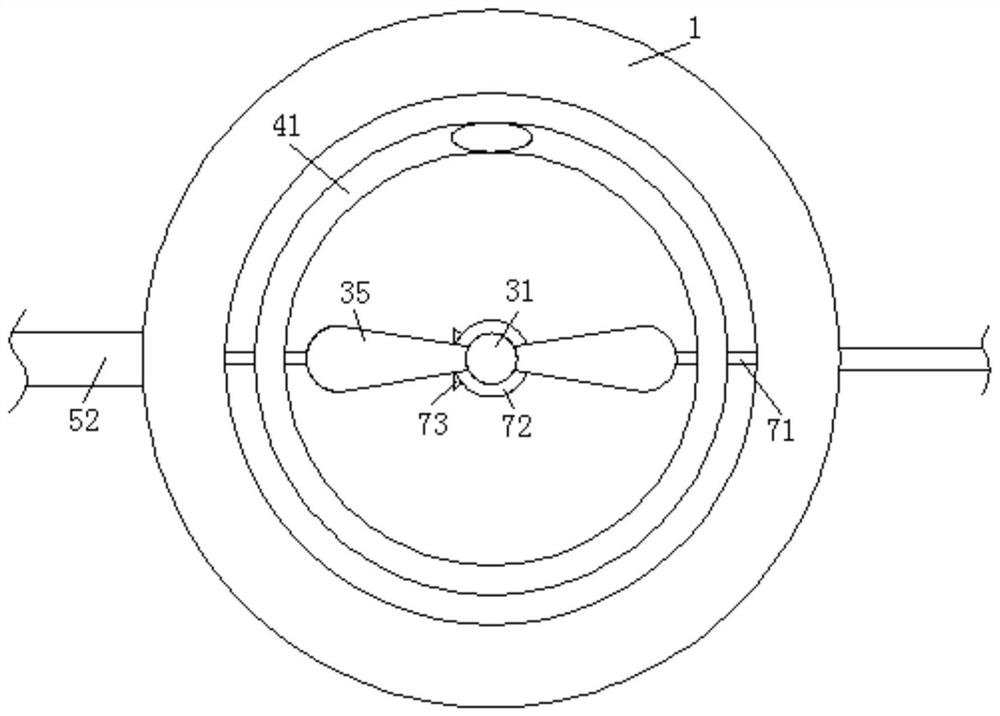

[0025] Example: such as Figure 1-5 As shown, a water circulation cooling device for battery colloid production equipment according to the present invention includes a water tank 1 with an open upper end, a tank cover mechanism 2 is provided on the upper surface of the water tank 1, and a stirring mechanism 3 is provided on the tank cover mechanism 2 , and the lower end of the stirring mechanism 3 extends into the water tank 1, a heat exchange mechanism 4 is arranged on the position corresponding to the stirring mechanism 3 inside the water tank 1, and a water inlet and outlet mechanism 5 is arranged on the side wall of the water tank 1, and the water tank 1 A filtering mechanism 6 is arranged inside the water tank 1 , and a conveying mechanism 7 is arranged inside the water tank 1 , and one end of the conveying mechanism 7 extends into the water inlet and outlet mechanism 5 .

[0026] Wherein, the tank cover mechanism 2 includes a tank cover 21, the tank cover 21 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com