Polarizing material, polarizer and display panel

A display panel and polarizer technology, which is applied in the direction of optics, optical elements, polarizing elements, etc., can solve the problems of poor solubility, poor polarization characteristics, insufficient orientation degree, etc., achieve maximum solubility, maximum polarization degree, and improve light extraction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a polarizing material, comprising: reactive liquid crystal, 80-98%; monochromatic dichroic dye, 1-10%; photoinitiator, 0.1-2%; polymerization inhibitor, 0.05% by mass percentage -0.2%; surfactants, 0.05%-5%; and photoresist additives, 0.1-20%.

[0038] Specifically, in terms of structure, the reactive liquid crystals may include acrylic reactive liquid crystals and alkylene oxide reactive liquid crystals; in terms of liquid crystal phases, the reactive liquid crystals may include nematic reactive liquid crystals, near Crystal phase reactive liquid crystal.

[0039] The monochromatic dichroic dyes include cyan dyes, magenta dyes, yellow dyes and other dyes. When the monochromatic dichroic dye is a cyan dye, it is used to absorb red light. When the monochromatic dichroic dye is a magenta dye, it is used to absorb green light. When the monochromatic dichroic dye is a yellow dye, it is used to absorb blue light.

[0040] The photoinitiator is a ...

Embodiment 2

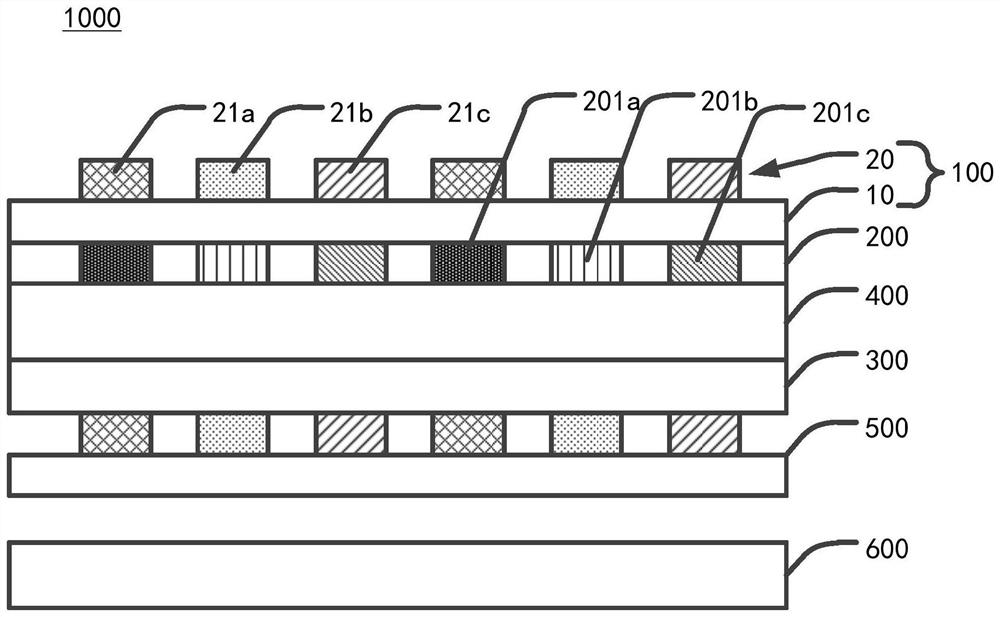

[0076] This embodiment provides a polarizing material, a polarizer and a display panel, which include most of the technical solutions of Embodiment 1, the difference being that the polarizing layer is disposed between the liquid crystal layer and the color filter substrate.

[0077] Such as Figure 5 as shown, Figure 5 It is a schematic structural diagram of the display panel described in Embodiment 2 of the present application.

[0078] This embodiment provides a display panel 2000 , the polarizing layer 100 is disposed between the liquid crystal layer 400 and the color filter substrate 200 .

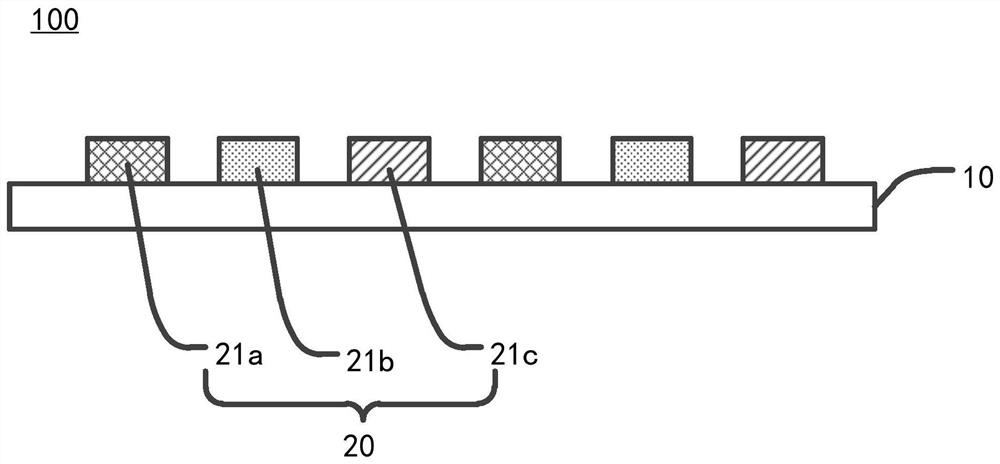

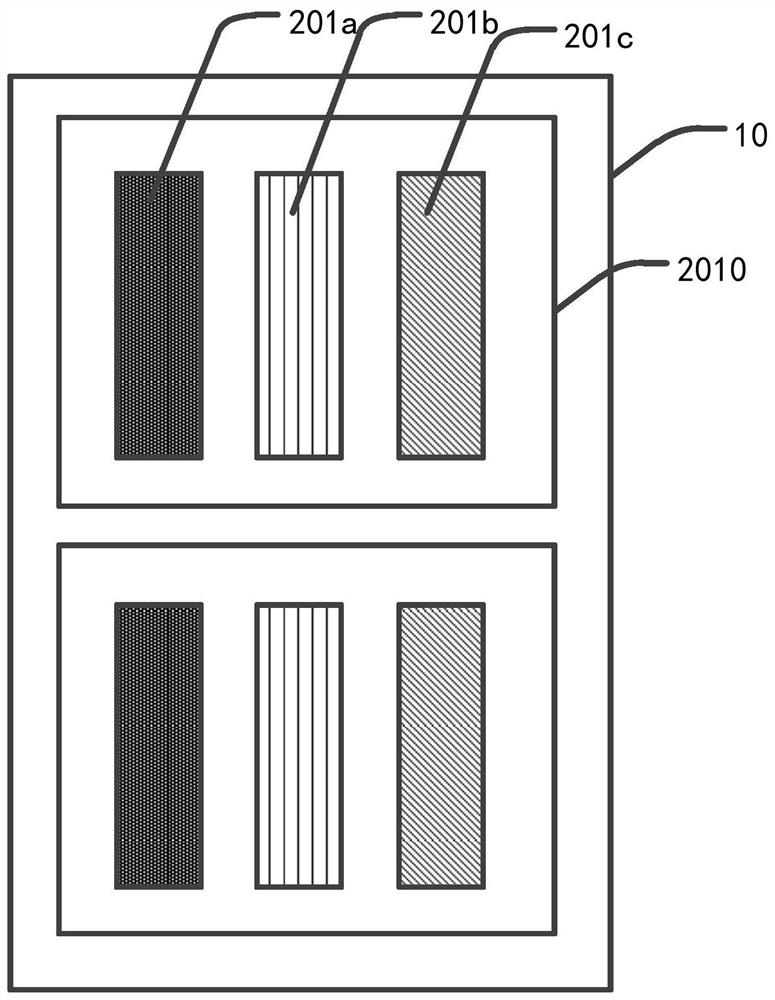

[0079] The color filter substrate 200 includes a red color-resist unit 201a, a green color-resist unit 201b, and a blue color-resist unit 201c. In the polarizing layer 20, the polarizing unit 21 includes a cyan polarizing unit 21a, a magenta polarizing unit 21b, Yellow polarizing unit 21c. Wherein, the cyan polarizing unit 21a corresponds to the red color resist unit 201a, and is u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap