Positive electrode active material, production method thereof and non-aqueous electrolyte secondary battery

A positive electrode active material and non-aqueous electrolyte technology, applied in the field of non-aqueous electrolyte secondary batteries, can solve problems such as poor capacity and poor overcharge cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

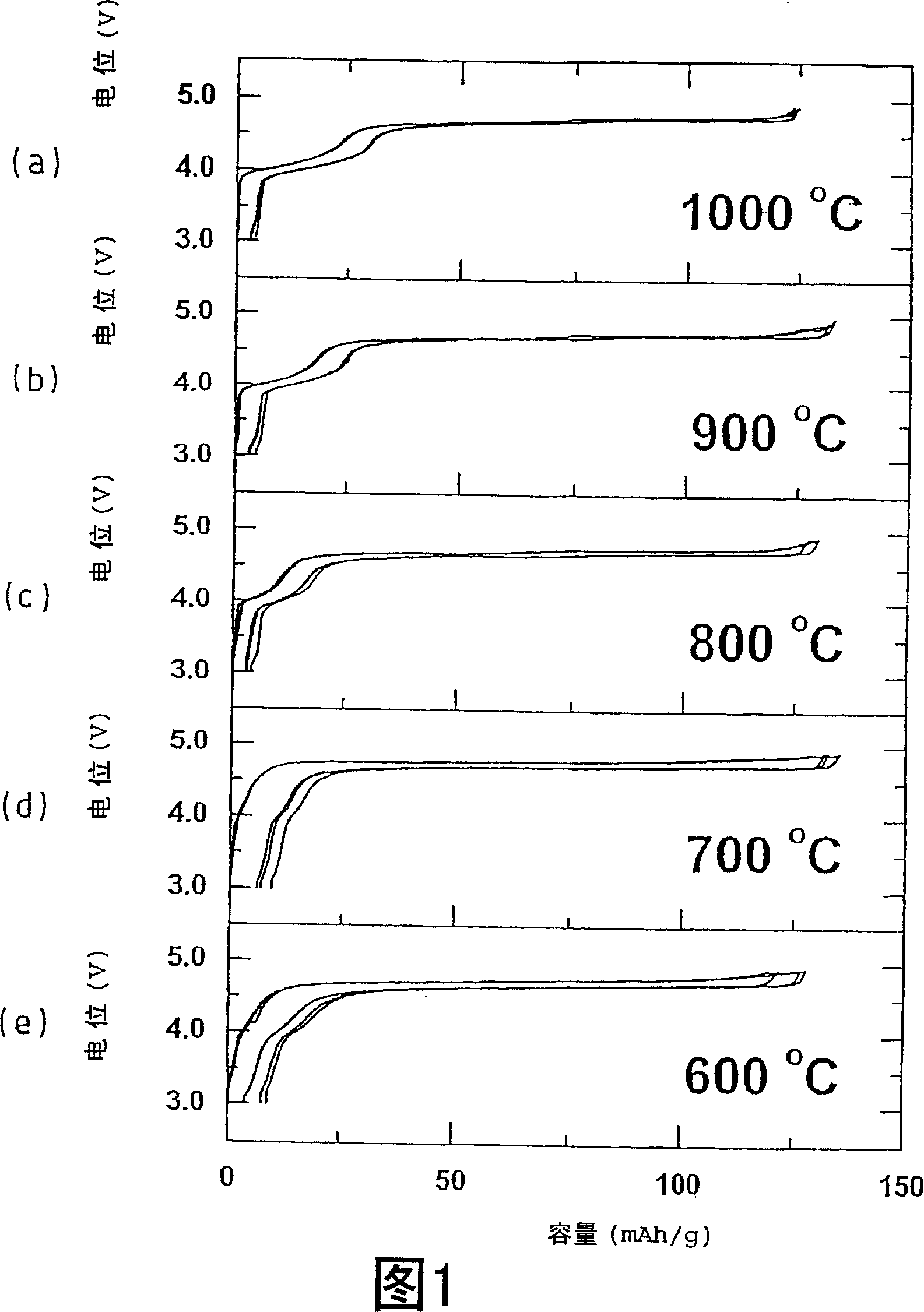

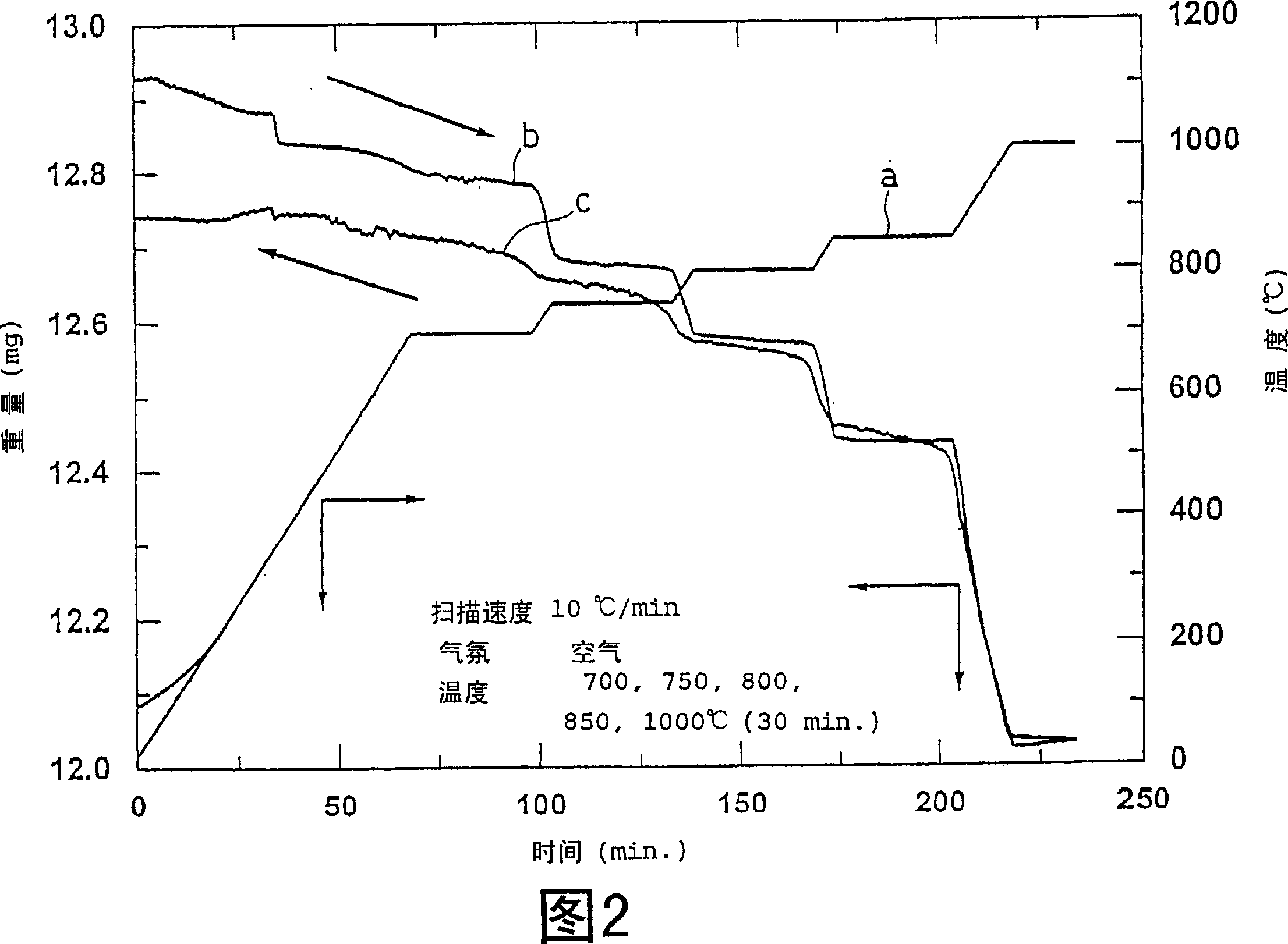

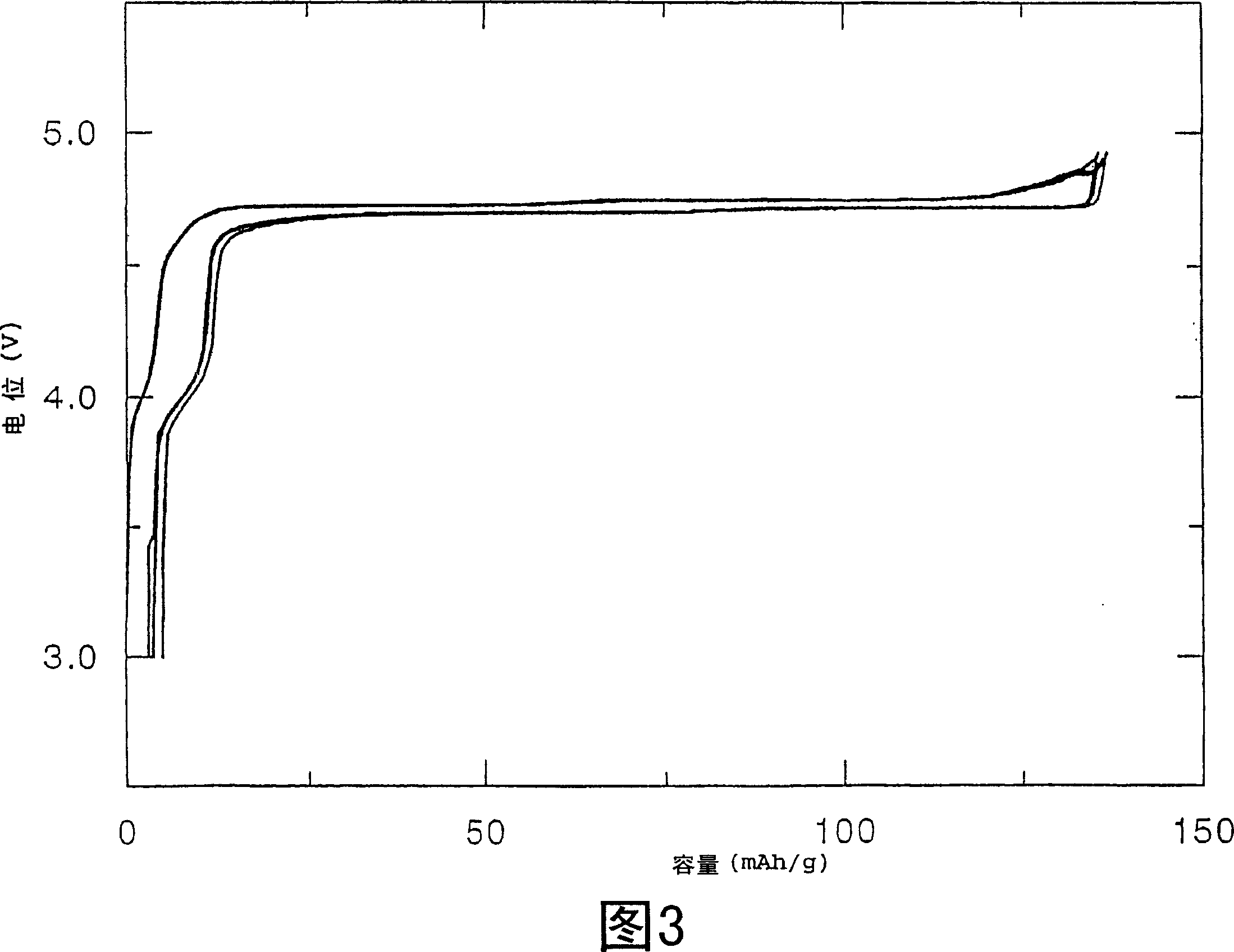

[0270] Three different types of cathode active material samples were prepared under the synthesis conditions shown in section (3) above. The [Ni 1 / 4 mn 3 / 4 ](OH) 2 and LiOH·H 2 O Thoroughly mix the resulting mixture to form particles, which are then fired to obtain a positive electrode active material. Therefore, the composition of the resulting cathode active material is Li[Ni 1 / 2 mn 3 / 2 ]O 4 . Oxygen content varies according to synthesis conditions. The electrochemical analysis of the obtained cathode active material was performed in the manner shown in the above section (1).

preparation Embodiment 1

[0272] The ambient temperature was increased from room temperature to 1000°C in approximately 3 hours, maintained at 1000°C for 12 hours, and then decreased from 1000°C to room temperature in 2 hours.

preparation Embodiment 2

[0274] Increase ambient temperature from room temperature to 1000°C in approximately 3 hours, maintain at 1000°C for 12 hours, decrease from 1000°C to 700°C in 30 minutes, maintain at 700°C for 48 hours, then increase from 700°C in 1.5 hours °C was lowered to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com