Production equipment and preparation method of efficient COD remover

A technology of production equipment and remover, applied in the direction of chemical instruments and methods, dissolving, mixing machines, etc., can solve the problems of insufficient efficiency of production equipment and poor use of production equipment, so as to improve safety and use effect, and facilitate cleaning work, easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

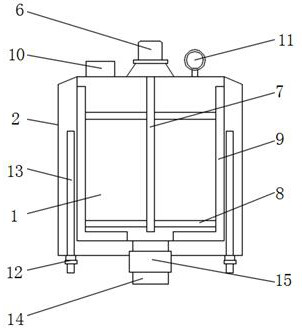

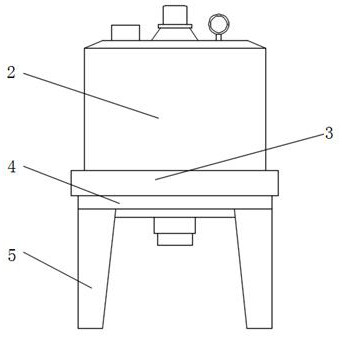

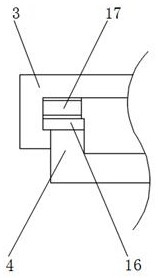

[0031] refer to Figure 1-6 , a high-efficiency COD remover production equipment and preparation method thereof, comprising a tank body 1, characterized in that the outer surface of the tank body 1 is provided with a jacket 2, and the outer surface of the jacket 2 is provided with a fixing frame 3, The lower end of the fixed frame 3 is fixedly mounted with a mounting frame 4, the outer surface of the lower end of the mounting frame 4 is fixedly mounted with a support leg 5, and the middle of the upper end of the tank body 1 is fixedly mounted with a motor 6, and the output end of the motor 6 is fixedly connected with a rotating shaft 7, and the rotating shaft The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com