Slicing equipment for special-shaped materials with adjustable thickness

A special-shaped material and slicing technology, applied in metal processing and other directions, can solve the problems affecting the quality of traditional Chinese medicinal materials, uneven slice thickness, loss of effective components, etc., and achieve the effect of improving slicing efficiency, adjustable slice thickness, and uniform slice thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

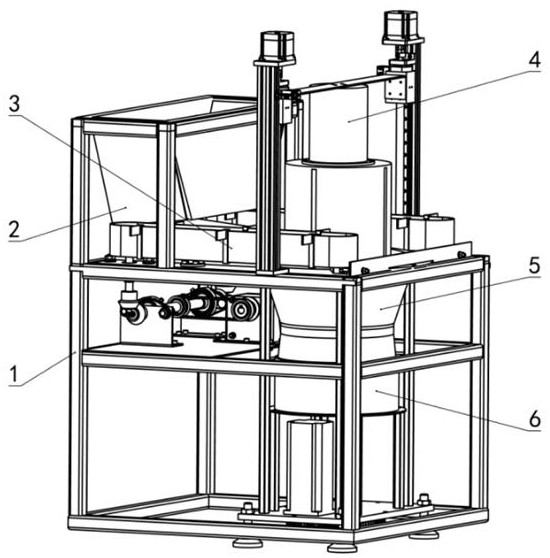

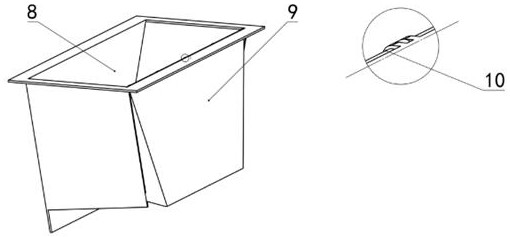

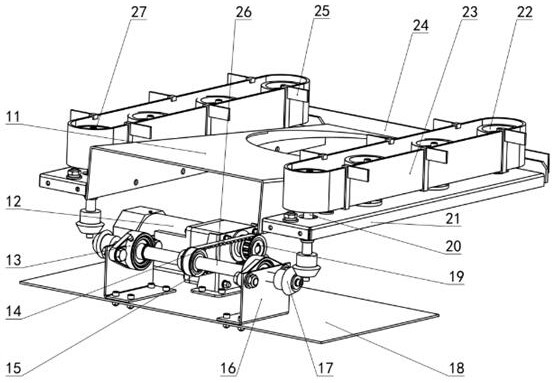

[0042] Example 1: as Figure 1-19 As shown, the thickness-adjustable special-shaped material slicing equipment includes a frame 1, a material storage mechanism 2, a conveying mechanism 3, a pressing mechanism 4, a slicing mechanism 5, a discharging mechanism 6, an automatic thickness adjustment mechanism 7, and the material storage mechanism 2 is fixed On the top side of the frame 1, it is used to store special-shaped materials; the conveying mechanism 3 is fixed on the frame and is located under the storage mechanism 2. The conveying mechanism 3 transports the special-shaped materials in the storage mechanism 2 to the slicing mechanism 5, and presses The feeding mechanism 4 is fixed on the frame and is located above the slicing mechanism 5, the pressing mechanism 4 is used to compress the special-shaped material in the slicing mechanism 5, and the automatic thickness adjustment mechanism 7 is arranged in the slicing mechanism 5 to adjust the thickness of the slice; The discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com