A car coat board assembly and car

A coat and assembly technology, which is applied in the automobile coat plate assembly and the automotive field, can solve the problems of complex assembly, high welding cost, and heavy weight of the body configuration, and achieve the effects of convenient assembly, reduced welding cost, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

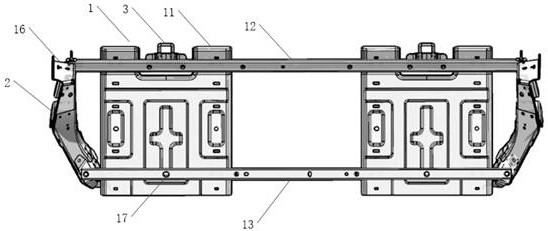

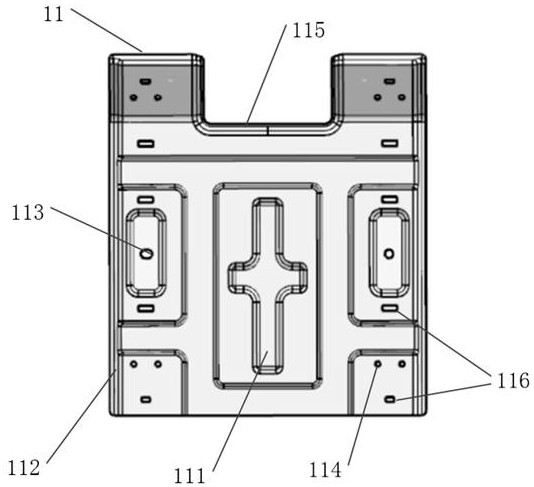

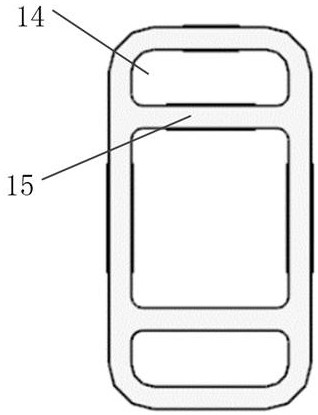

[0037] like Figure 1-6As shown, an automobile coat panel assembly includes a coat panel assembly 1 and a coat panel bracket assembly 2. The coat panel assembly 1 includes a support plate 11, an upper beam 12 and a lower beam 13. The upper frame of the support plate 11 and The upper beam 12 is fixedly connected, the lower frame of the support plate 11 and the lower beam 13 are fixedly connected, the support plate 11 is an axisymmetric structure, the upper beam 12 and the lower beam 13 are respectively axisymmetric structures, and the support plate 11 is extruded through an aluminum plate. The thickness of the plate 11 is 1.5~2.5mm, the length and width are 300~600mm, there are two support plates 11, the two support plates 11 are symmetrically arranged on the upper beam 12, and the two support plates 11 are symmetrically arranged on the lower beam 13. There are two cap plate bracket assemblies 2, one of which is fixedly installed on one end of the upper beam 12 and one end of t...

Embodiment 2

[0043] like Figure 7 As shown, a four-seat SUV model vehicle includes a rear seat assembly 4, a rear instrument assembly 5, a luggage compartment trim panel 6 and the car coat panel assembly in Embodiment 1, and the rear seat assembly 4 , The rear instrument assembly 5 and the luggage compartment trim panel 6 are respectively connected with the car coat panel assembly. The rear seat assembly 4 is connected to the mounting hole 116 of the support plate 11 with a snap in the S4 area, and the rear instrument assembly 5 is connected to the lower beam 13 of the car coat panel assembly with a snap in the S5 area. , the luggage compartment trim panel 6 is connected to the mounting hole 116 of the support plate 11 by snaps in the S3 area, and the rear seat assembly 4, the rear instrument assembly 5, the luggage compartment trim panel 6 and the car coat and cap are completed. Fixed connection of plate assembly. The overall frame is regular, and with the cooperation of various manufa...

Embodiment 3

[0045] like Figure 8 As shown, a five-seat SUV model vehicle includes a five-seat SUV model rear seat assembly 9 and the coat panel bracket assembly 2 in Embodiment 1, and the five-seat SUV model rear seat assembly 9 passes through the seat The chair bracket is fixed on the coat board support assembly 2, and the seat support is fixed on the coat board support assembly 2 by bolt connection in the area S6. In this embodiment, the difference from the four-seat SUV model is that the coat panel bracket assembly 2 does not need to be connected to the coat panel assembly 1, and is fixed at the set position of the vehicle body, which can be set by those skilled in the art.

[0046] As mentioned above, the present invention has the following beneficial effects:

[0047] 1) By setting up a new type of coat panel assembly structure, the requirements for the rear seat configuration of the four-seat version and the five-seat version are met at the same time, replacing the traditional rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com