Multifunctional dual-motor redundancy braking system and control method

A braking system and dual-motor technology, applied in the field of servo braking systems, can solve problems such as difficulty in satisfying the vehicle's servo braking capacity and the inability of a single electro-hydraulic servo brake solution, to facilitate function expansion, optimize brake pressure distribution, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

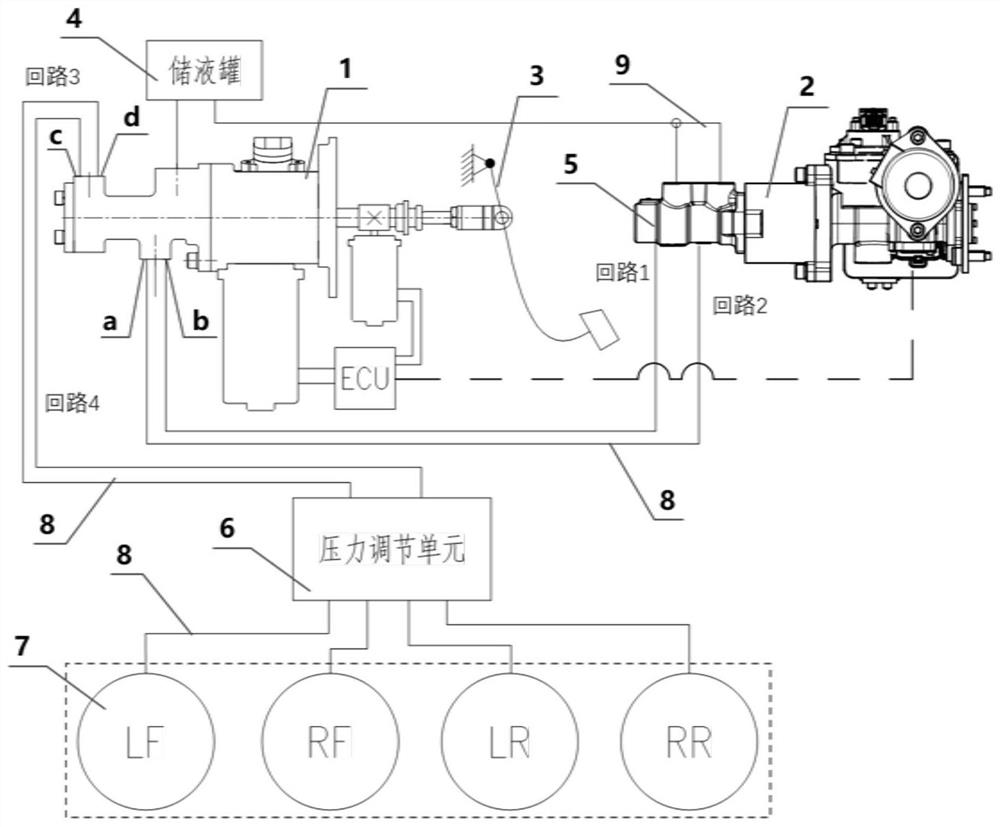

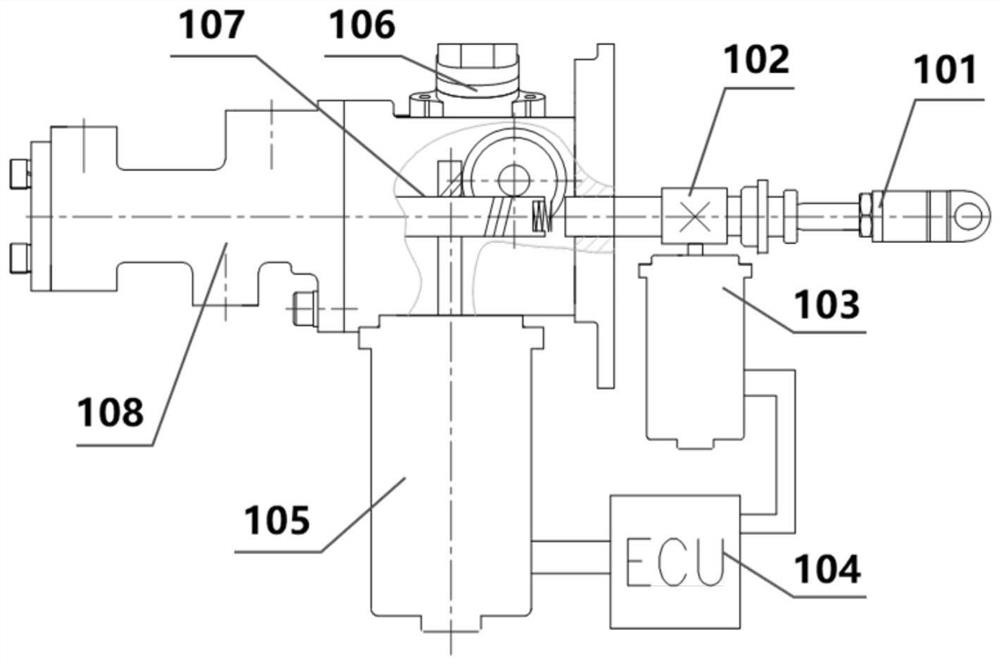

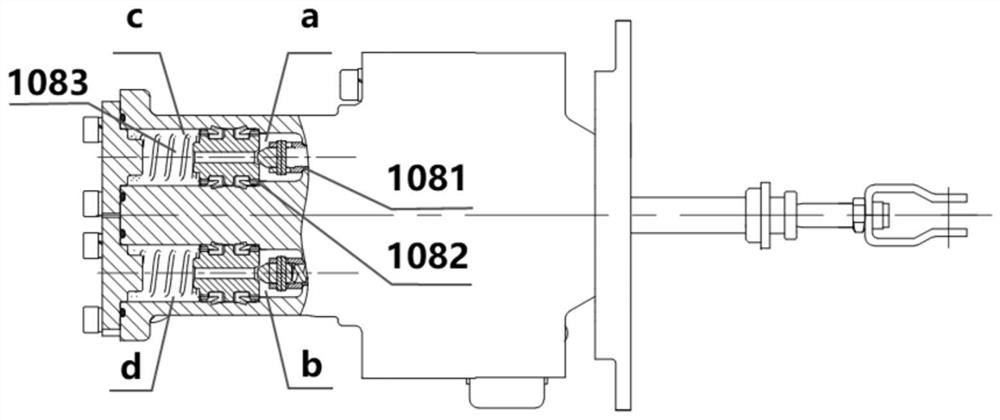

[0067] Please refer to Figure 1 to Figure 4 , this embodiment provides a multifunctional dual-motor redundant braking system, which mainly includes a main electro-hydraulic servo brake assembly 1, an auxiliary electro-hydraulic servo brake assembly 2, a brake pedal assembly 3, and a liquid storage tank 4 , brake master cylinder 5, pressure regulating unit 6 and brake group 7. Among them: the main electro-hydraulic servo brake assembly 1 and the auxiliary electro-hydraulic servo brake assembly 2 are connected through CAN bus communication, and the two ends of the main electro-hydraulic servo brake assembly 1 are respectively connected to the brake pedal assembly 3 and The parallel master cylinder 108 is connected, and the auxiliary electro-hydraulic servo brake assembly 2 is connected with the brake master cylinder 5 .

[0068] In this embodiment, the fluid storage tank 4 is used to provide brake fluid to the brake master cylinder 5 and the parallel master cylinder 108 . The...

Embodiment 2

[0112] The structure of the dual-motor redundant braking system in this embodiment is basically the same as in Embodiment 1, the difference being that: the first brake set in this embodiment is composed of a left rear wheel brake LR and a right rear wheel brake RR; The brake group is composed of left front wheel brake LF and right front wheel brake RF. The four oil outlets of the pressure regulating unit 6 are respectively connected with LR, RR, LF and RF. At this time, the braking system is an H-shaped arrangement.

Embodiment 3

[0114]The structure of the dual-motor redundant braking system in this embodiment is basically the same as that in Embodiment 1, the difference being that the first brake group in this embodiment consists of a left front wheel brake LF and a right rear wheel brake RR, and the second The brake group consists of the right front wheel brake RF and the left rear wheel brake LR. The four oil outlets of the pressure regulating unit 6 are respectively connected with LF, RR, RF and LR. At this time, the brake system is an X-shaped arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com