B-column reinforcing structure and vehicle

A technology for strengthening structures and B-pillars, which is applied to superstructures, vehicle parts, superstructure sub-assemblies, etc., can solve problems such as the inability to take into account the strength and energy absorption requirements of the door sill side beams, complex processing procedures, and a large number of parts, etc., to achieve Improve head passability, increase structural strength, and reduce cavity volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

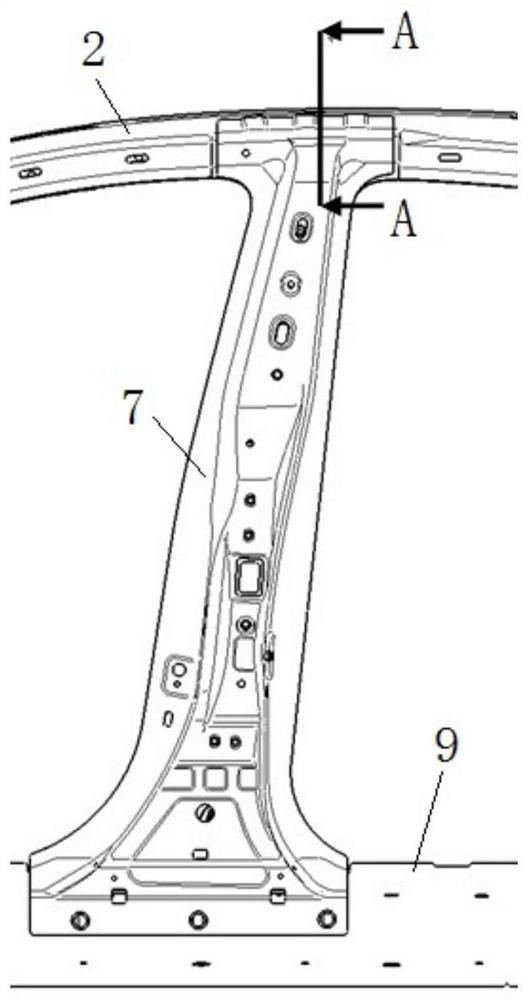

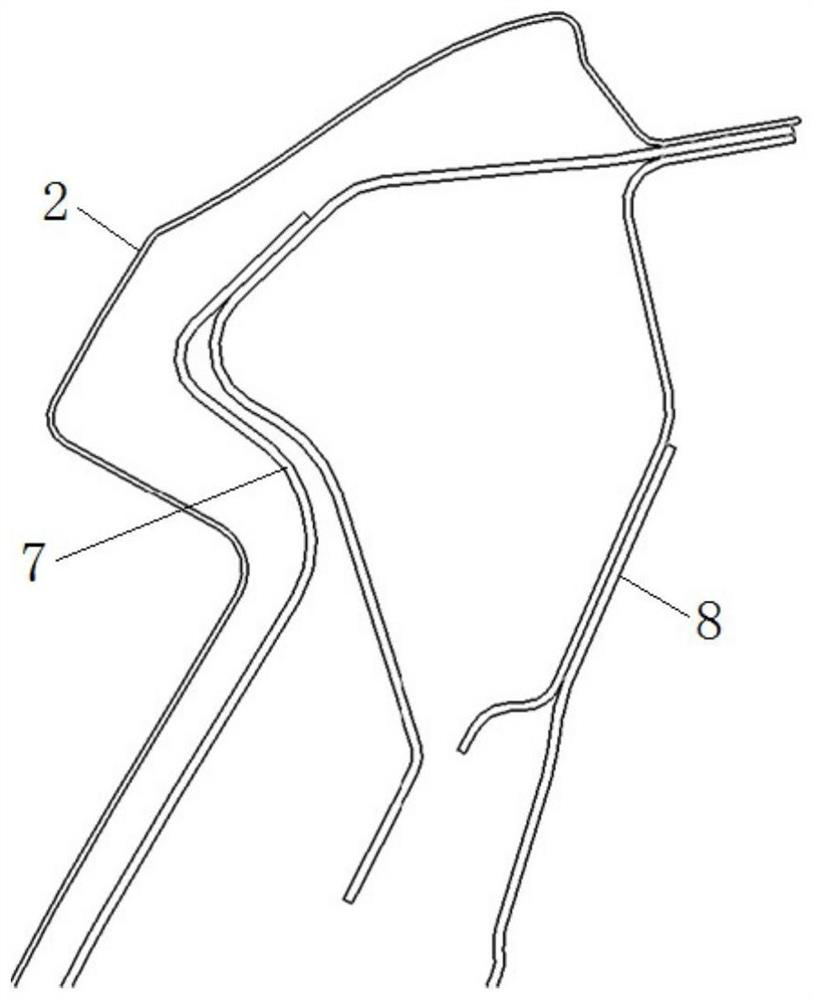

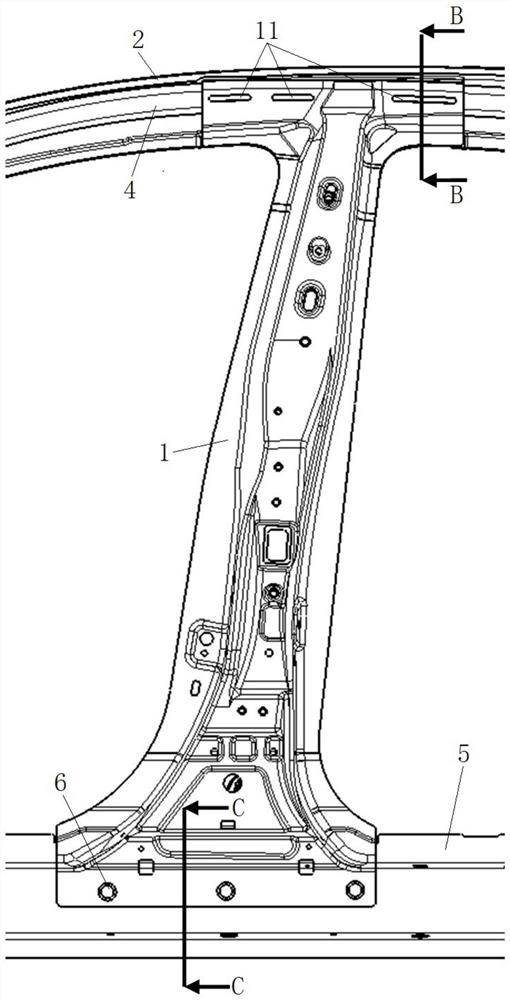

[0025] see Figure 3 to Figure 6 , the B-pillar reinforcement structure shown includes a B-pillar reinforcement 1 arranged between the B-pillar inner panel 3 and the side wall outer panel 2, the tensile strength of the B-pillar reinforcement 1 is ≥1800Mpa, and the elongation is ≥5 %. The upper part of the B-pillar reinforcement 1 is surrounded by the B-pillar inner panel 3 to form a transverse accommodation chamber. A tubular reinforcement 4 is arranged in the transverse accommodation chamber. The outer wall of the tubular reinforcement 4 is welded and fixed to the transverse accommodation chamber. The lower end of the B-pillar reinforcement 1 is fixedly connected to the aluminum alloy door sill side beam 5 through a mounting piece.

[0026] The B-pillar reinforcement 1 is in the shape of an "I", and the upper part of the B-pillar reinforcement 1 is designed in con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com