Aluminum coil segmentation method for reducing metal fatigue

An aluminum coil and fatigue technology, which is applied in the field of aluminum coil segmentation to reduce metal fatigue, can solve problems such as aluminum coil metal fatigue, aluminum buckle plate deformation, aluminum plate metal fatigue, etc., to reduce fatigue damage, avoid metal fatigue, and reduce bending The effect of fold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

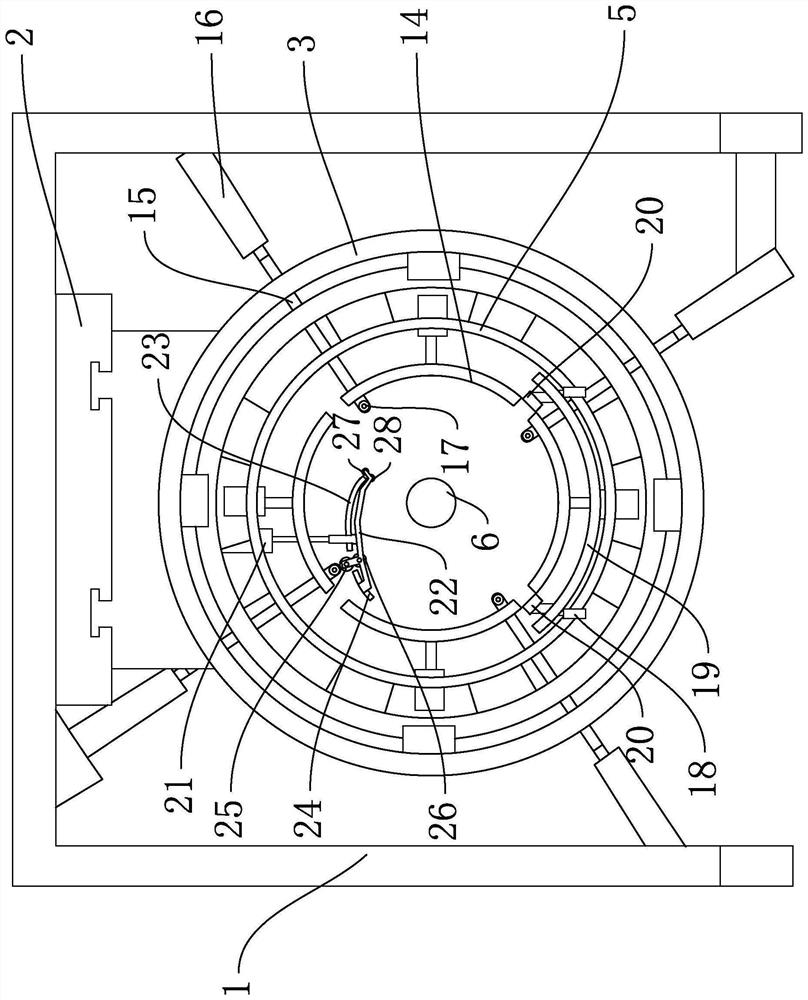

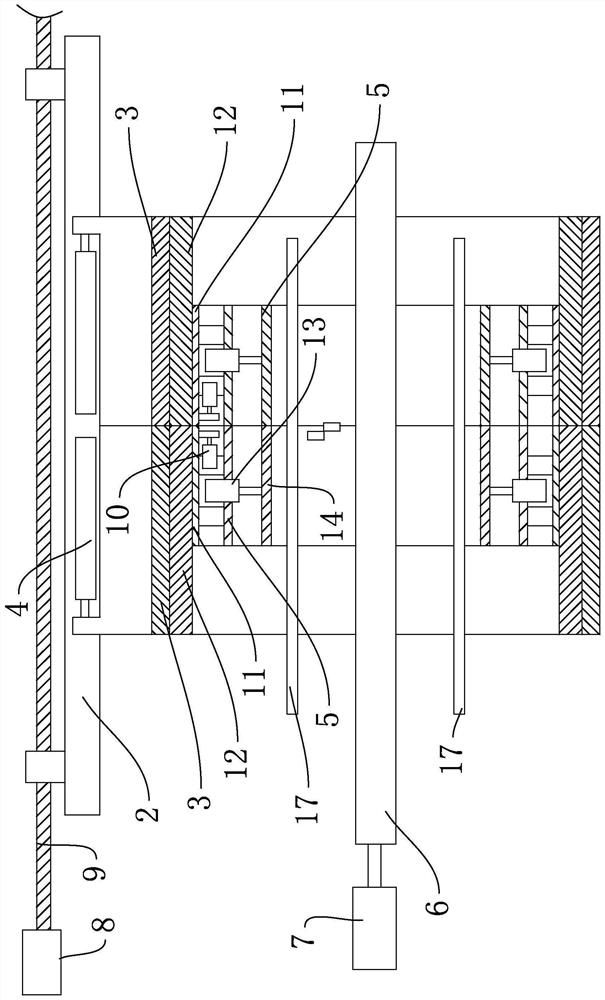

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0028] A method for splitting aluminum coils for reducing metal fatigue, comprising the following steps:

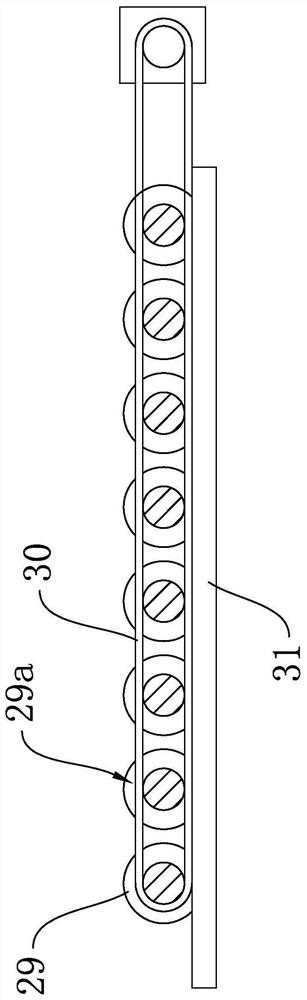

[0029] S1, set the aluminum coil on the unwinding shaft 6 of the splitting device, cut off one end of the aluminum coil and form two aluminum strip ports, pass the two aluminum strip ports through the first guide tube 27, the second guide tube 28 and Connected and fixed on the two rotating rings 5;

[0030] S2, the square reel 6 and the rotating ring 5 are all rotated to keep the aluminum strip tightly attached to the inner surface of the support block 14 forming a ring-shaped support area, and then gradually wind up and make the aluminum strip have no gap after winding;

[0031] S3, cutting until the aluminum coil o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com