Double-drum anti-swing portal frame trolley system

A double-drum and reel technology, applied in hoisting devices, hoisting equipment braking devices, load suspension components, etc., can solve the problems of cumbersome wire rope winding system, long production cycle, and cramped maintenance space, etc., to reduce The effect of manufacturing labor costs, shortening the production cycle, and avoiding multiple bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

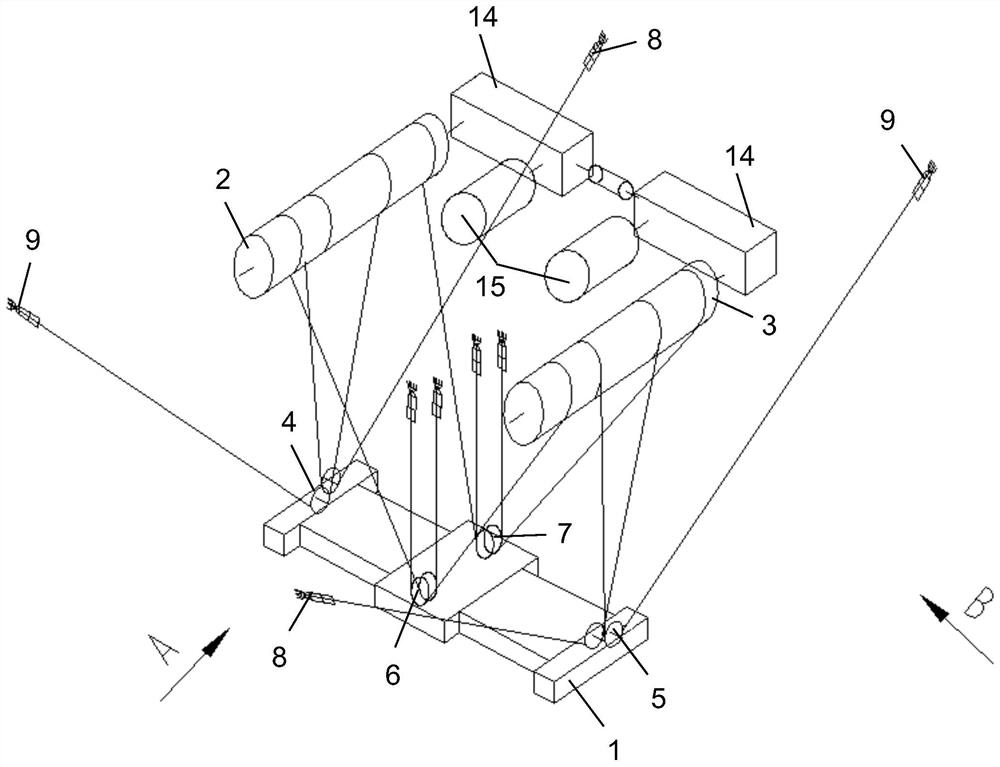

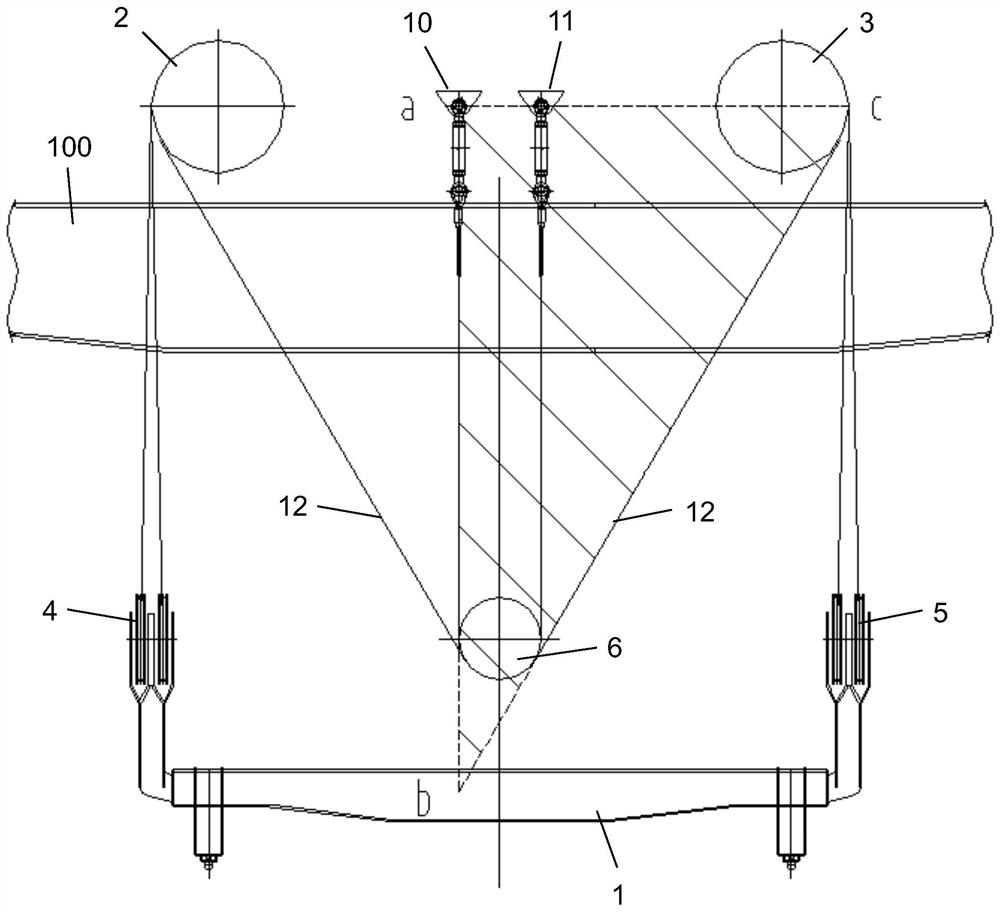

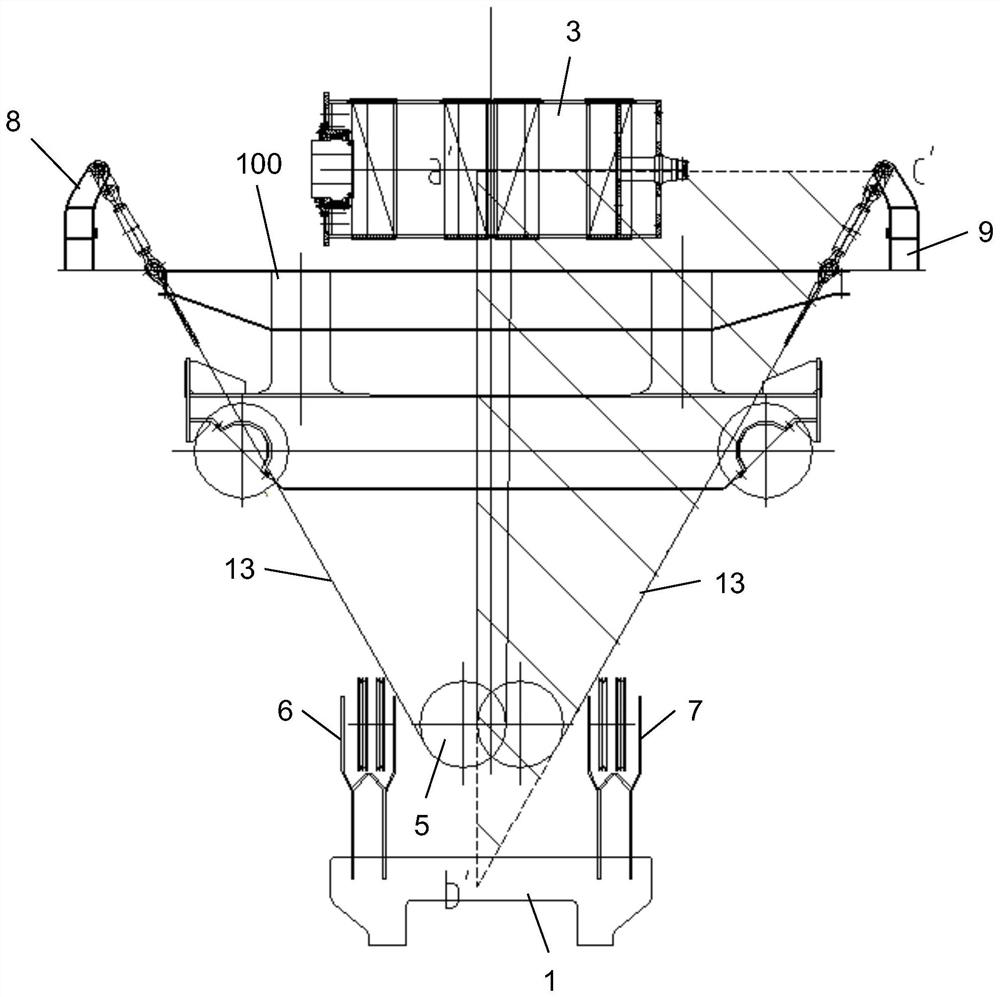

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] Please combine figure 1 As shown, a double-drum anti-sway mast trolley system provided by the present invention includes a spreader upper frame 1, and two parallel and symmetrically arranged first lifting drums 2 and second lifting drums located above the spreader upper frame 1. The lifting reel 3, the first lifting reel 2 and the second lifting reel 3 are connected with a motor 15 through a reduction box 14, and the two reduction boxes are arranged on the same side, and are connected by a coupling 16 or a single motor 15 Rigid connection, two motors 15 are arranged in parallel inside the first lifting drum 2 / the second lifting drum 3 to realize electrical and mechanical synchronization.

[0032] The first block 4 and the second block 5 are respectively installed on the upper surface length of the upper frame 1 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com