Cutting device for reducing aluminum coil metal fatigue

An aluminum coil and fatigue technology is applied in the field of dividing devices for reducing the metal fatigue of aluminum coils, which can solve the problems of large bending range and metal fatigue, and achieve the effects of reducing fatigue damage, improving hardness, and avoiding multiple bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

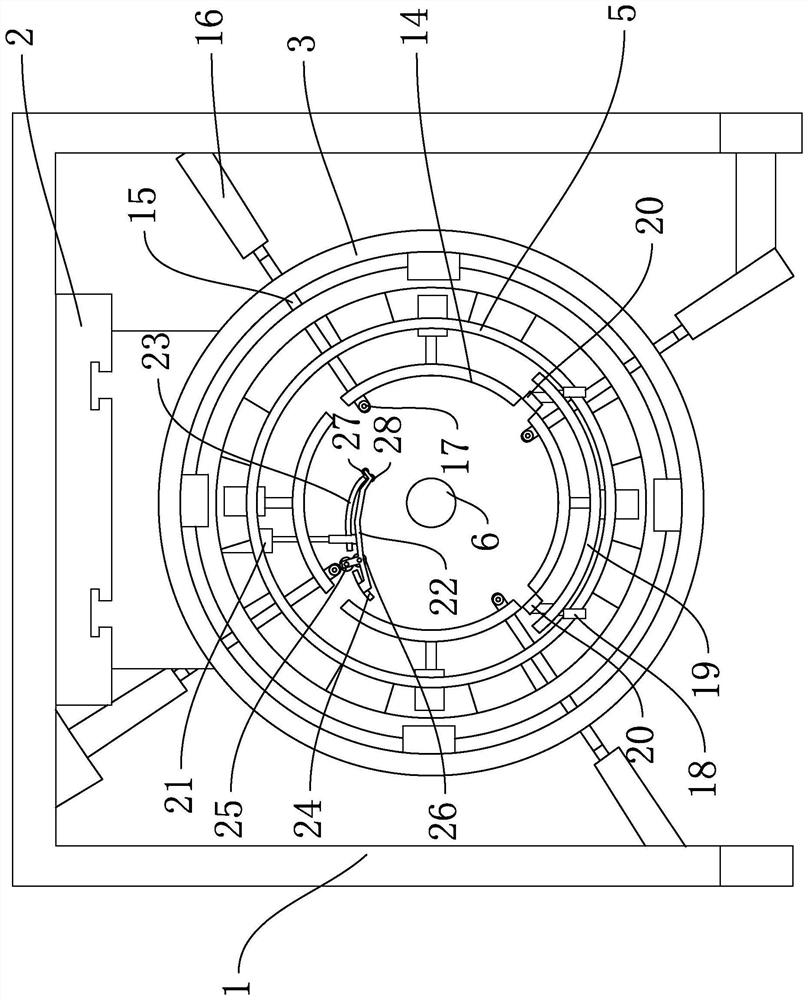

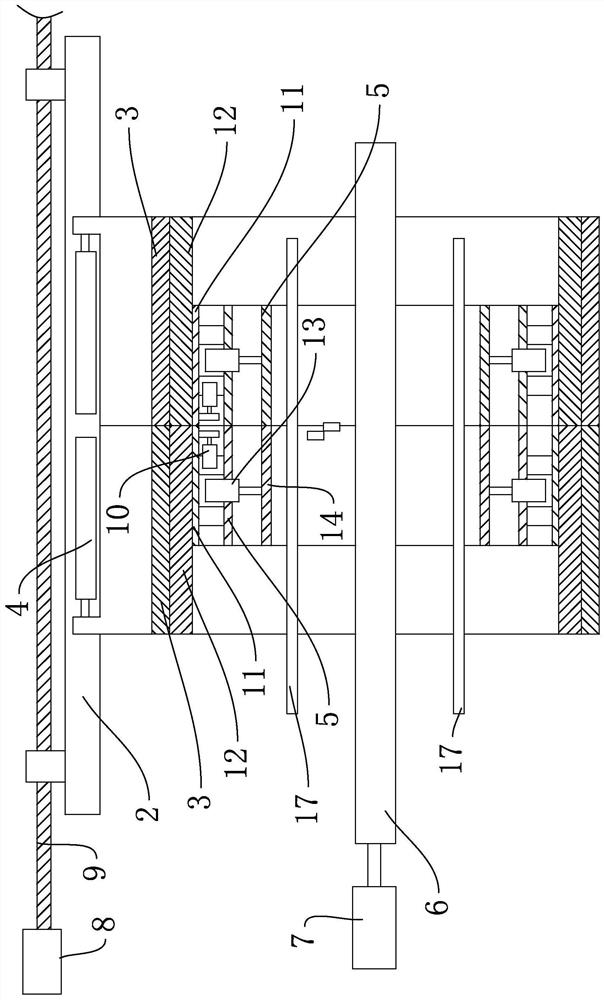

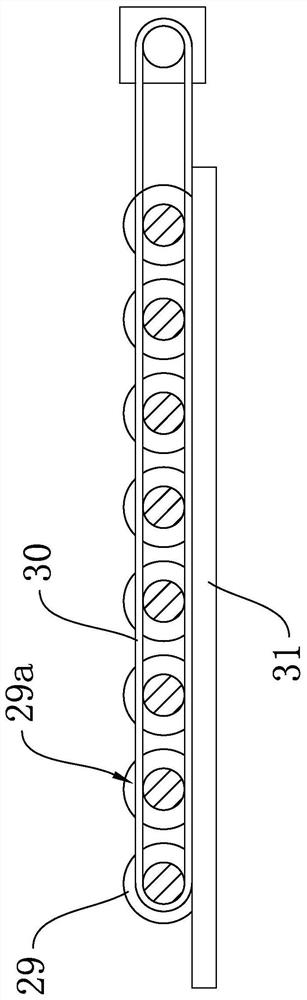

[0022] Such as Figure 1 to Figure 3 As shown, a splitting device for reducing metal fatigue of aluminum coils includes a frame 1, on which a movable frame 2 that can translate in translation is arranged, and the movable frame 2 is slidably provided with two moving rings 3, and the movable frame 2 is fixed with Two symmetrically arranged first push rod motors 4, the push rods of the two first push rod motors 4 are respectively connected to the two moving circles 3 and can drive the two moving circles 3 to move in opposite directions; There is a rotating ring 5 that can rotate relative to the moving ring 3, and the rotating ring 5 is used for rewinding the slit aluminum coils. The driving mechanism that drives the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com