Adjustable assembly type lifting appliance

A prefabricated and adjustable technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of single structure and small scope of application, and achieve the effect of reducing safety hazards, reducing difficulty of hoisting, and firm and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

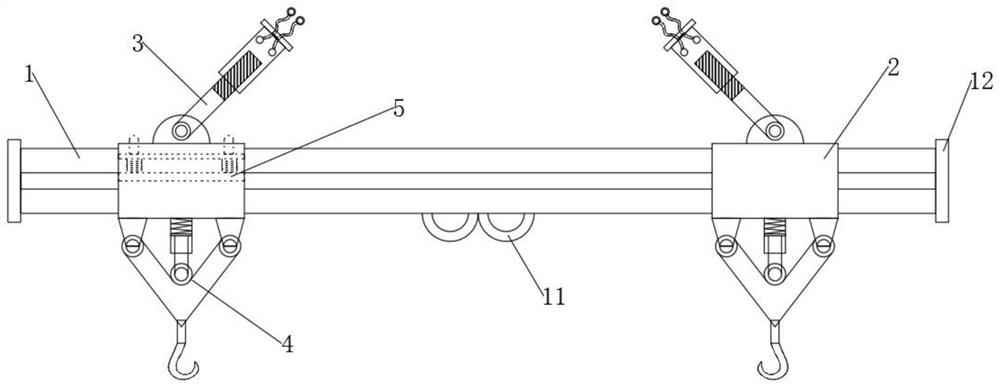

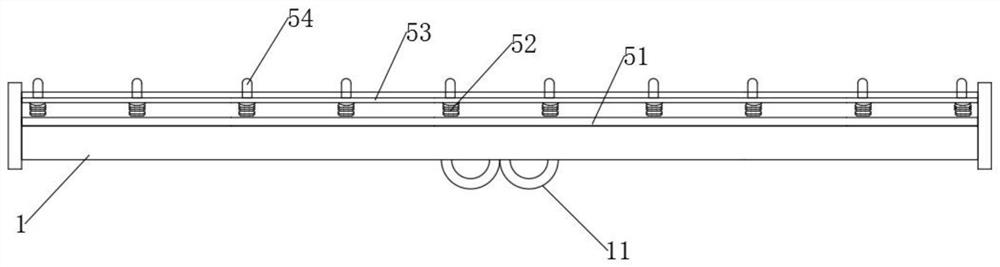

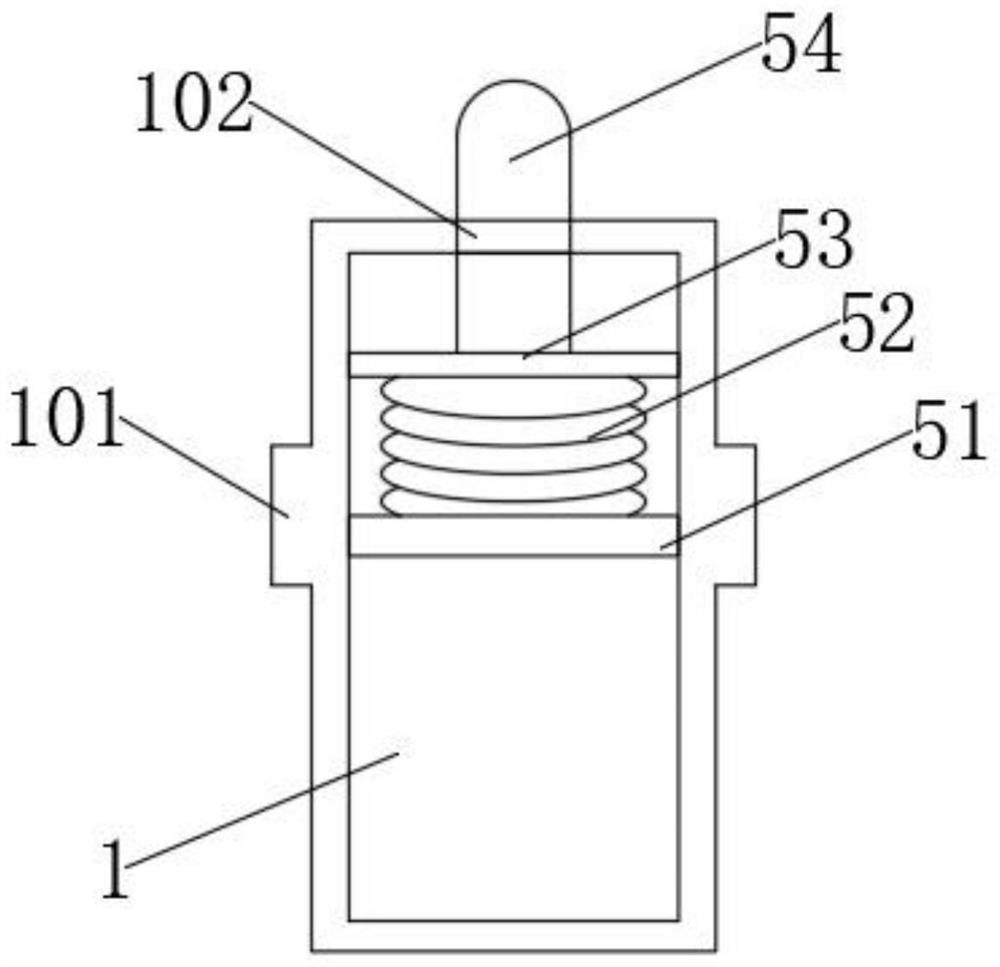

[0034] like Figure 1-8 As shown, an adjustable assembled hoisting device includes a hanging beam 1, the hanging beam 1 is set as a hollow structure, and the upper side of the hanging beam 1 is evenly opened with a first through hole 102;

[0035] A sliding seat 2 is slidably socketed on the suspension beam 1; the sliding seat 2 is provided with a hollow structure, and the upper side of the sliding seat 2 is provided with a second through hole 22; the first through hole 102 and The diameters of the second through holes 22 are the same.

[0036] The interior of the suspension beam 1 is provided with an elastic clip mechanism 5 laterally; the elastic clip mechanism 5 includes a fixed plate 51 and a connecting plate 53; the fixed plate 51 and the connecting plate 53 are located inside the hanging beam 1, wherein the The fixed plate 51 is horizontally fixedly installed in the suspension beam 1; the connecting plate 53 is connected with the fixed plate 51 through the spring group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com