Drying room with dry and wet gas separation function

A technology of drying room and function, applied in the field of drying room, can solve the problems of inability to separate dry and wet gas, increase energy consumption, increase drying cost, etc., so as to improve drying efficiency and drying uniformity, improve drying The effect of utilization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

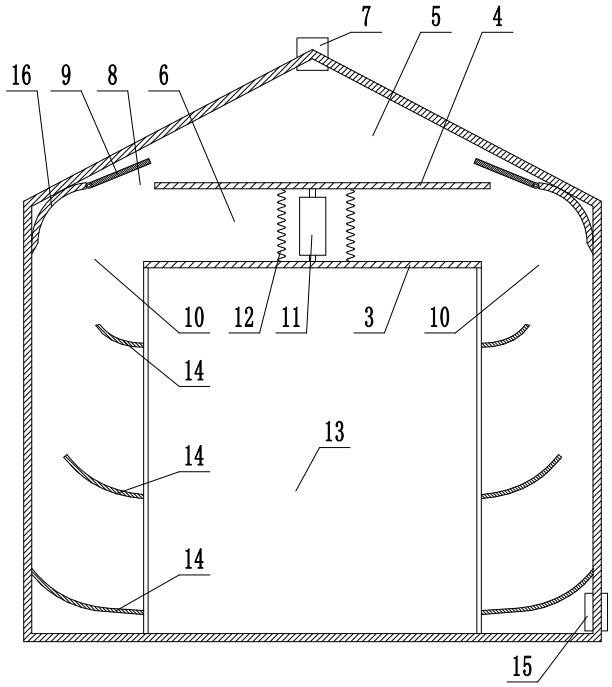

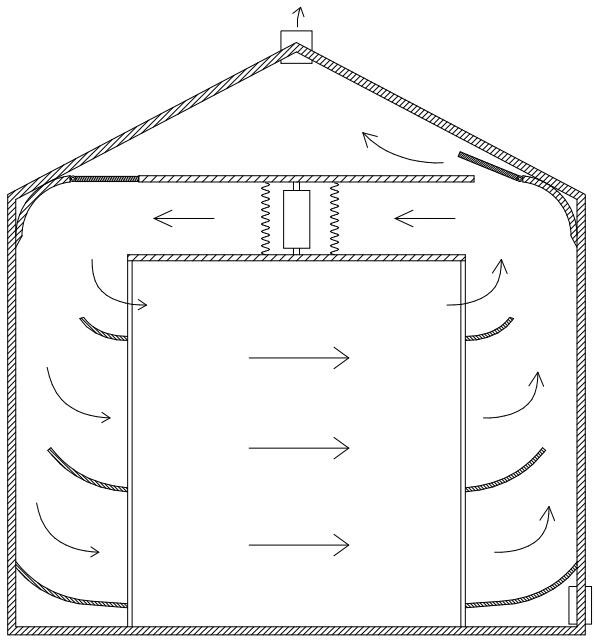

[0024] Referring to the accompanying drawings, the drying room with the function of separating dry and wet gas includes a box body 1 roughly in the shape of a cuboid. The front and rear lengths of the box body 1 are greater than the left and right widths. Door 2, secondly, in the box body 1, be provided with the middle partition 3 that box body 1 inner cavity is divided into the upper chamber and the lower chamber, the space of the lower chamber is greater than the space of the upper chamber, in addition, in the upper chamber There is an upper partition 4 that separates the upper chamber into an upper moisture accumulation chamber 5 and a lower blast chamber 6. Secondly, in order to perform moisture removal and ventilation, the top of the moisture accumulation chamber 5 is provided with a humidifier. The moisture discharge port 7 for air discharge, the damp discharge port 7 can be equipped with a damper and a fan to block the moisture discharge port 7 as required, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com