Seedling raising frame body for agricultural production

A seedling raising frame and agricultural technology, applied in the field of agriculture, can solve the problems affecting the service life of the seedling raising frame, dripping, rust and corrosion of the frame, and achieve the effect of reducing long-term contact, increasing the service life, and preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Please refer to Figure 1-Figure 6 , the specific embodiments of the present invention are as follows:

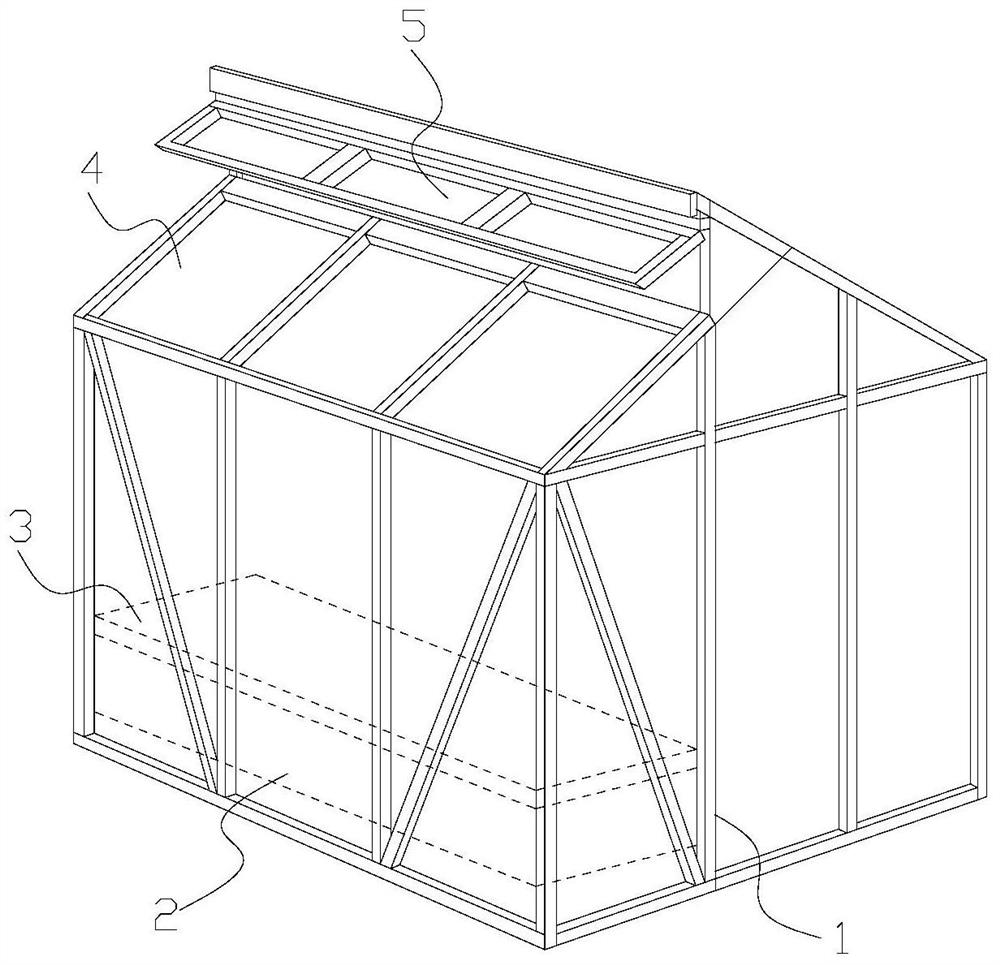

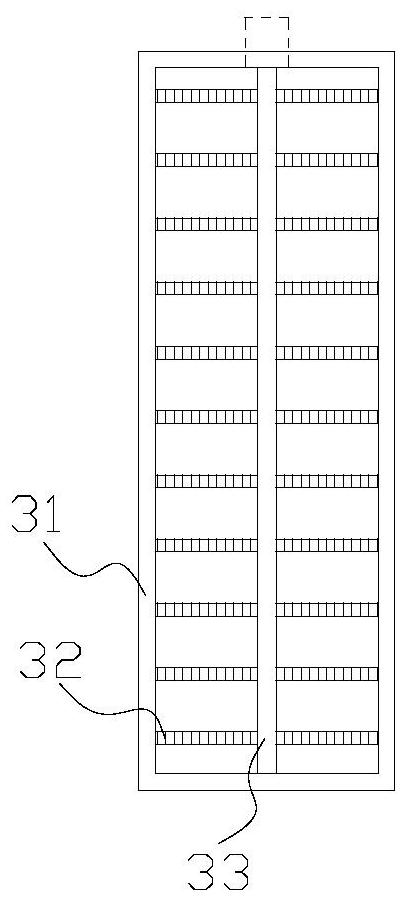

[0029] Its structure includes a frame 1, an outer box body 2, a placement frame 3, a top cover 4, and an air vent 5. The outer box body 2 is installed on the outside of the frame 1 and welded together, and the placement frame 3 is horizontally installed on the frame 1 inside and mechanically connected, the top cover 4 is obliquely installed on the upper end of the frame 1 and fixedly connected, the air vent 5 is located on the left side of the upper end of the top cover 4 and is an integrated structure; the placement frame 3 includes a bracket 31. Limiting plate 32 and drainage port 33. The limiting plate 32 is embedded and installed inside the bracket 31 and welded together. The drainage port 33 is located at the lower end of the bracket 31 and is inclined. The limiting plate 32 interval distribution.

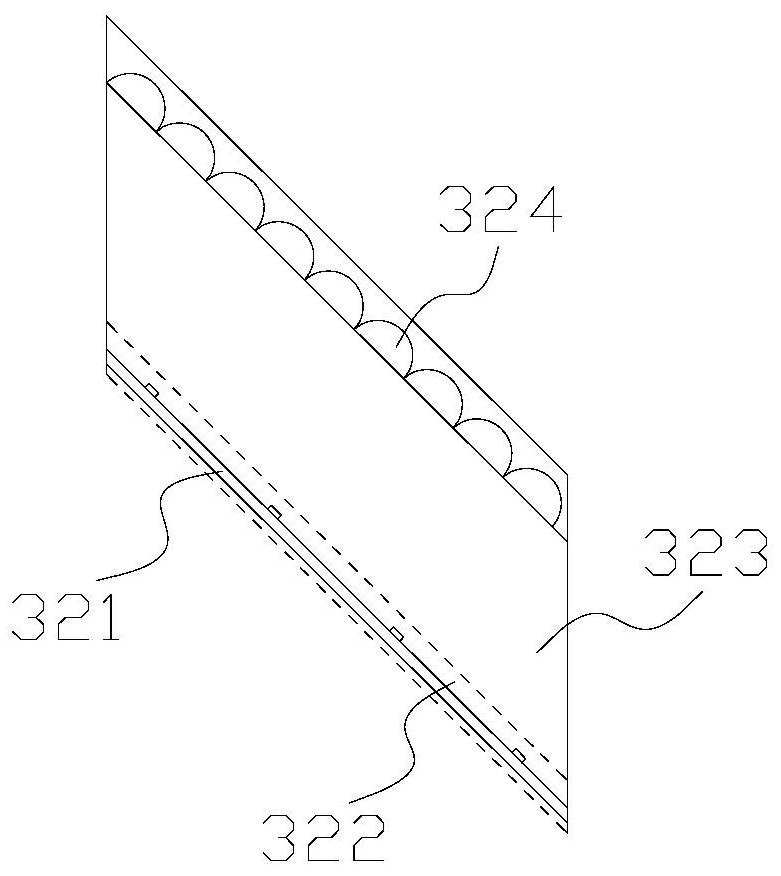

[0030] refer to image 3 The limiting plate 32 in...

Embodiment 2

[0036] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0037] The support block 24d includes an inner block d1, a pillar d2, and a contact structure d3. The pillar d2 is vertically embedded inside the inner block d1 and engaged with each other. The contact structure d3 is horizontally installed on the upper end of the pillar d2 and fixed connect.

[0038] refer to Figure 7, the contact structure d3 includes a support body d31, a notch d32, a sloping plate d33, a drain d34, and a collection structure d35. The notch d32 is provided on the outside of the support body d31 and is an integrated structure. The front end of the support body d31 is fixedly connected, the drain d34 is located at the front end of the support body d31 and between the sloping plates d33, the collection structure d35 is embedded and installed inside the support body d31 and is flexibly connected to the seedling tray and guide the drippi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com