Punching equipment for valve spring retainer

A spring seat and punching technology, which is used in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of difficult collection of waste, large safety hazards, and impact on the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

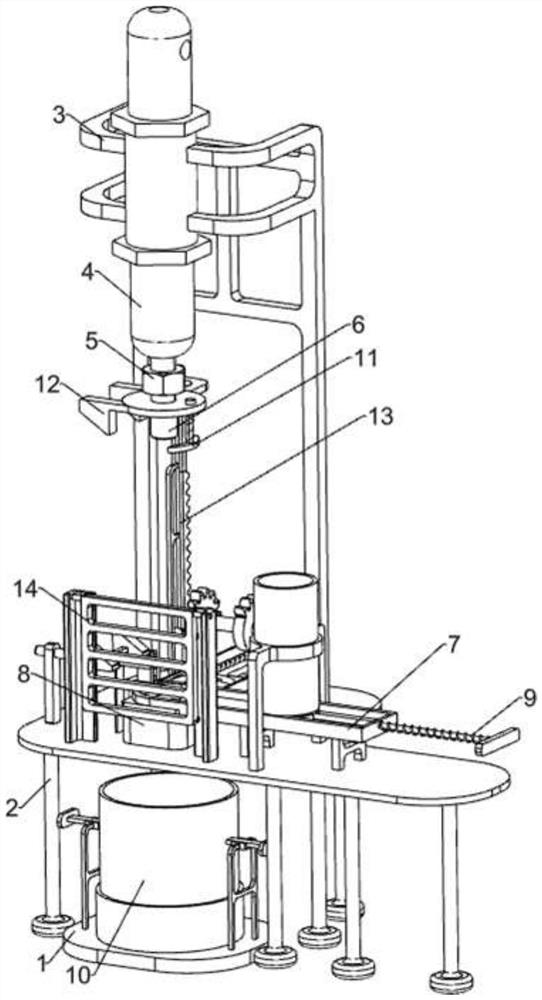

[0045] A punching device for valve spring seats such as figure 1 As shown, it includes a bottom plate 1, a support seat 2, an installation seat 3, a cylinder 4, a push rod 5, a punching module 6, a placement groove plate 7, a pressure block 8, a pushing mechanism 9 and a collection mechanism 10. The top of the bottom plate 1 A collection mechanism 10 is provided, which is provided with a support seat 2, the support seat 2 is located above the bottom plate 1, and the rear side of the top of the support seat 2 is provided with a mounting seat 3, and the upper part of the mounting seat 3 is provided with a cylinder 4, and the telescopic end of the cylinder 4 is connected with a pusher The rod 5, the bottom of the push rod 5 is provided with a punching module 6, the top of the support seat 2 is provided with a placement trough 7, the placement trough 7 is provided with a pushing mechanism 9, and the left side of the top of the support seat 2 is provided with a bearing block 8, The...

Embodiment 2

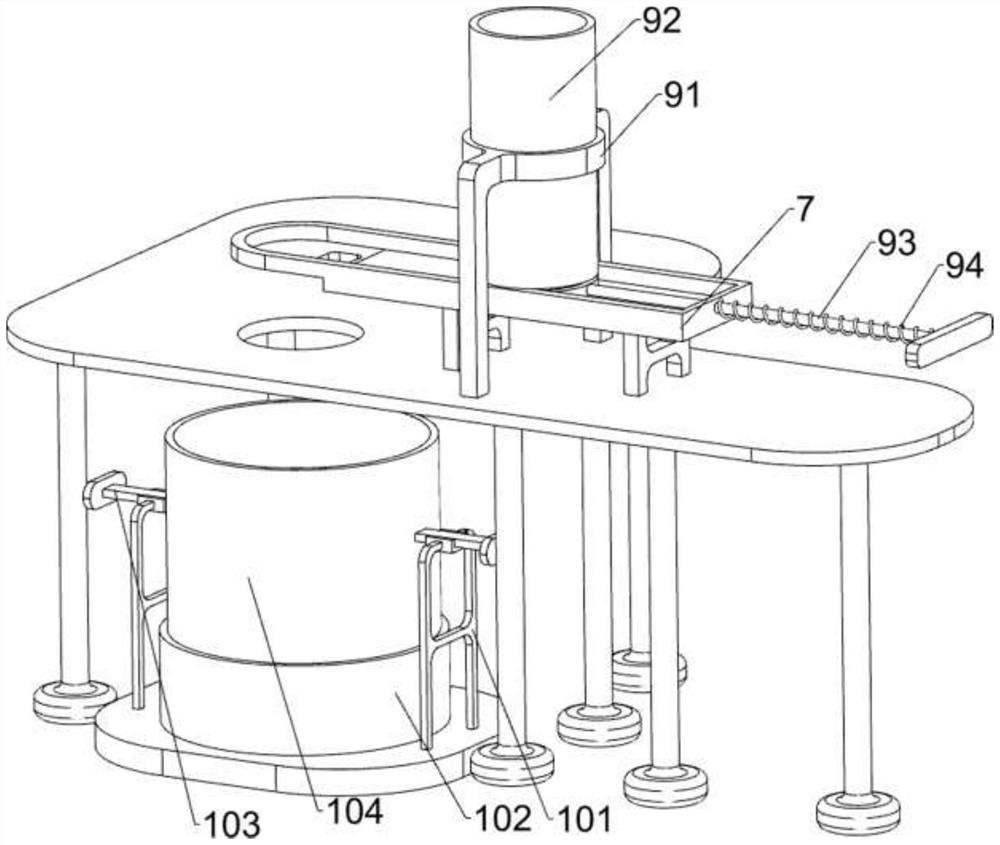

[0048] On the basis of Example 1, such as figure 2 and Figure 6 As shown, the pushing mechanism 9 includes a support frame 91, a placement frame 92, a feeding hand push rod 93 and a first back-moving spring 94, and the sliding type on the right side of the placement slot plate 7 is provided with a feeding hand push rod 93, and the feeding hand A first return spring 94 is connected between the push rod 93 and the right side of the placement slot plate 7 , a support frame 91 is provided on the top of the support seat 2 , and a placement frame 92 is provided on the support frame 91 .

[0049] The staff can put the valve spring seat into the placement frame 92, and manually drive the feeding hand push rod 93 to move to the left to push the bottom valve spring seat to move to the left, and the first return spring 94 is compressed to complete the pushing. Seat moves to corresponding position, stops to promote feeding hand push rod 93, and first back-moving spring 94 resets and dr...

Embodiment 3

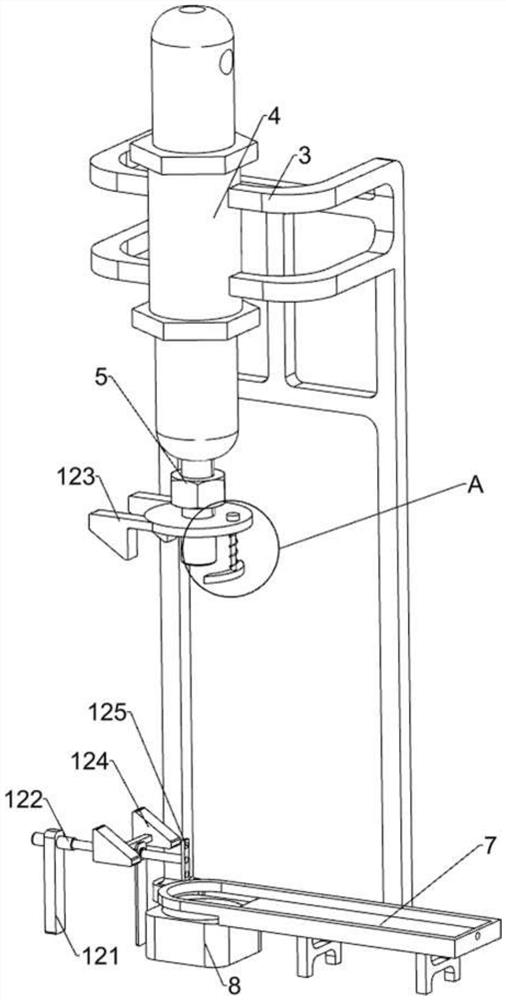

[0053] On the basis of Example 2, such as Figure 3 to Figure 9 As shown, a clamping mechanism 11 is also included. The clamping mechanism 11 includes a connecting rod 111, a clamping block 112 and a first limit spring 113. The right side of the punching module 6 is slidably provided with a connecting rod 111. The connecting rod 111 A clamping block 112 is provided at the bottom, and a first limit spring 113 is connected between the clamping block 112 and the bottom of the punching module 6 .

[0054] The punching module 6 moves downwards through the connecting rod 111 to drive the clamping block 112 to move downwards and contact the valve spring seat, the first limit spring 113 is compressed, and the connecting rod 111 stops moving, so that the valve spring seat in the punching hole can be fixed. Carry out limit, cooperate punching, punching is finished, and punching module 6 moves upwards and drives its upper part to move upwards, and clamping block 112 moves to no longer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com