Steel pipe cutting device for high-end equipment manufacturing

A technology for cutting devices and steel pipes, applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc., can solve the problems of uncontrollable cutting length and poor fixation, and achieve the effect of reducing safety hazards and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A steel pipe cutting device for high-end equipment manufacturing, such as Figure 1 to Figure 3 As shown, it includes a bottom plate 1, a base 2, a cutting mechanism 3 and a steel pipe flow mechanism 4, which is provided with a bottom plate 1 and a base 2, the base 2 is located on the right side below the bottom plate 1, and the right side of the top of the base 2 is provided with a cutting mechanism 3, the bottom plate 1. A steel pipe flow direction mechanism 4 is provided on the top.

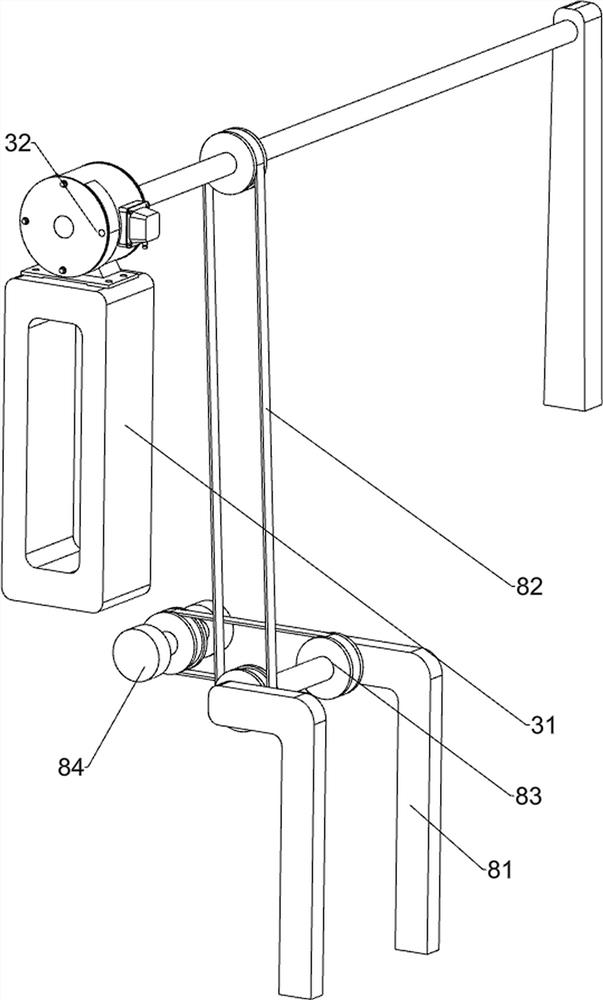

[0025] The cutting mechanism 3 includes a mounting base 31, a servo motor 32, a disc 33, a first connecting rod 34, a second connecting rod 35, a third connecting rod 36 and a cutting tool 37, and the right front side of the top of the base 2 is provided with a mounting base 31, The top of the mounting seat 31 is provided with a servo motor 32, the output shaft of the servo motor 32 is connected with a disc 33, the right side of the base 2 top is rotatably connected with a second connec...

Embodiment 2

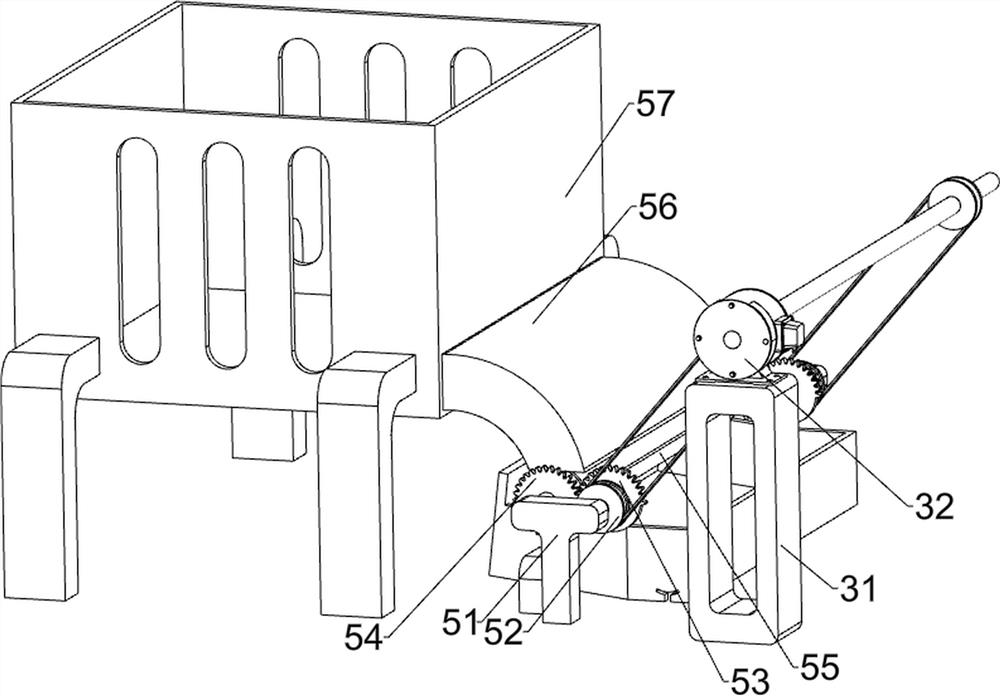

[0029] On the basis of Example 1, such as Figure 4 to Figure 7 As shown, an automatic feed mechanism 5 is also included, and the automatic feed mechanism 5 includes a mounting frame 51, a first pulley assembly 52, a sector gear 53, a transmission gear 54, a feed wheel 55, a feed chute 56 and a steel pipe to place Frame 57, the right side of base 2 top is symmetrically provided with mounting frame 51, is equipped with sector gear 53 and transmission gear 54 on the mounting frame 51, and sector gear 53 meshes with transmission gear 54, the rotating shaft of sector gear 53 and servo motor The first pulley assembly 52 is connected between the output shafts of 32, the feed wheel 55 is connected between the rotating shafts of the transmission gear 54, the steel pipe placement frame 57 is connected on the left side of the top of the base 2, and the steel pipe placement frame 57 bottom right side is connected with a The feed trough plate 56 is located above the feed wheel 55 .

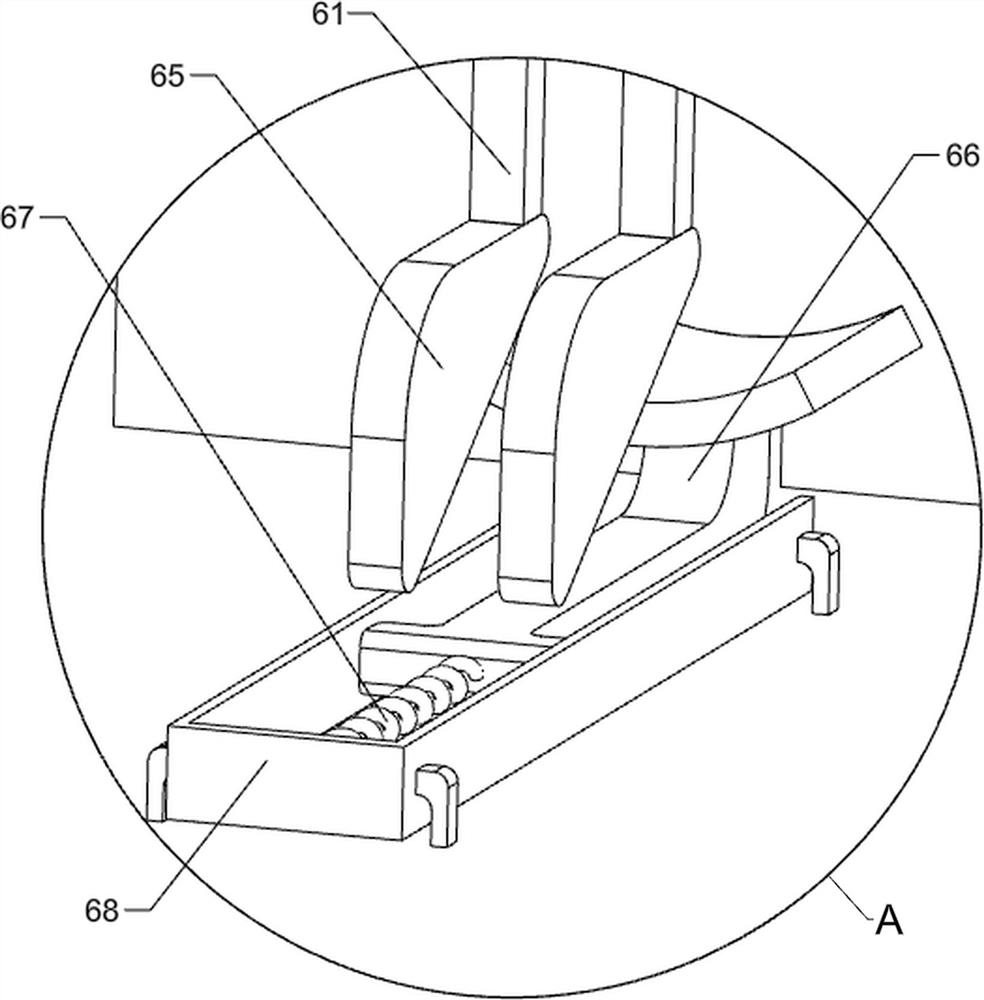

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com