Construction reinforcing steel bar straightening device and application method

A technology of building steel bars and pulleys, applied in the field of equipment and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

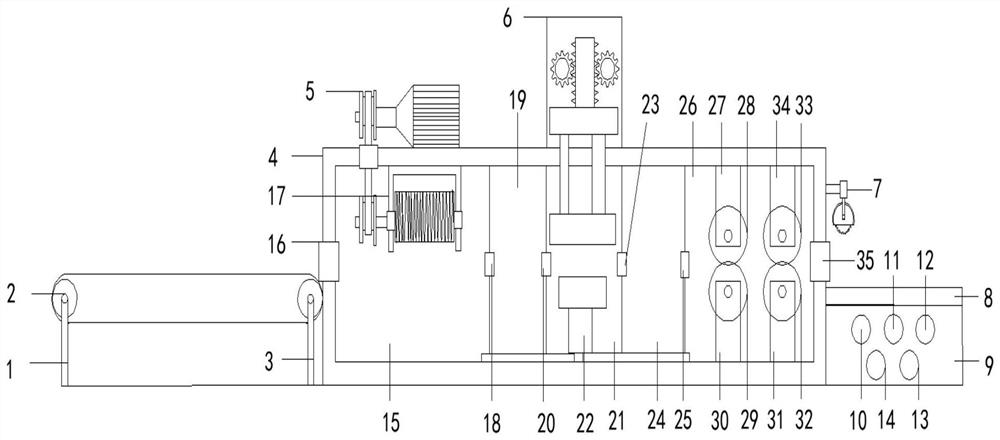

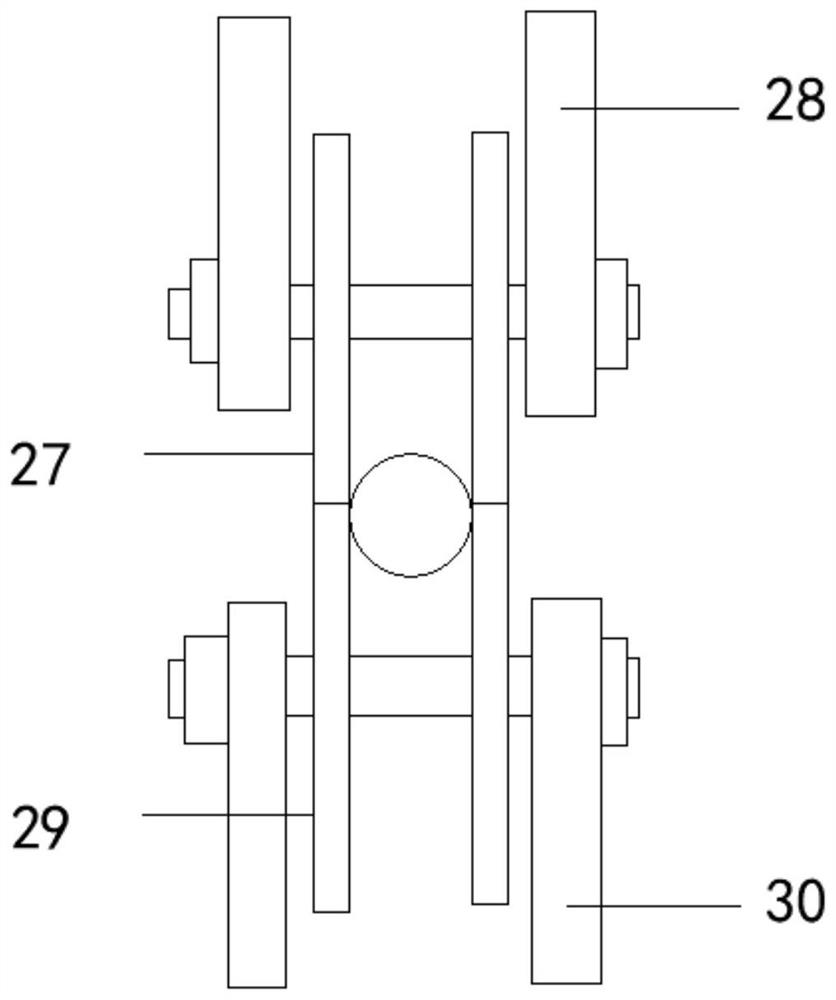

[0044] Such as Figure 1-10 As shown, the building steel bar straightening device includes a first support frame 1, a receiving platform 8, a T-shaped support platform 22, a first connecting rod 27, a second connecting rod 30, a third connecting rod 31 and a fourth connecting rod 34 , the upper end of the first support frame 1 is connected with a transmission mechanism 2, and the transmission mechanism 2 plays the role of transmitting steel bars, one end of the transmission mechanism 2 is connected with a second support frame 3, and one side of the second support frame 3 is connected with a box 4. The upper end of the box body 4 is connected with a driving mechanism 5, and the driving mechanism 5 provides a driving force for the conveying mechanism 17. The driving mechanism 5 and the box body 4 are connected together by welding, and one side of the driving mechanism 5 is connected with a fixing mechanism 6 , and the fixing mechanism 6 plays a role of fixing the steel bars, the...

Embodiment 2

[0054] The method of using the construction steel bar straightening device, the steps of the method are as follows:

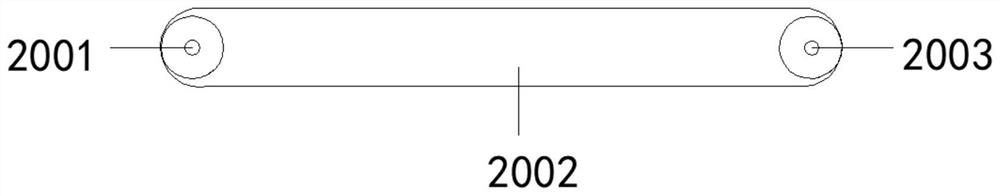

[0055]Step 1: first turn on the power, so that the entire building steel bar straightening device starts to run, then press the first button 10 to start the transmission mechanism 2 and the driving mechanism 5, and then put the steel bar on the conveyor belt 2002, at this time, the first The fifth pulley 2001 and the sixth pulley 2003 start to roll, and the rotation of the fifth pulley 2001 and the sixth pulley 2003 will drive the rotation of the conveyor belt 2002, and the rotation of the conveyor belt 2002 will allow steel bars to enter the delivery box 15 through the feed port 16 ;

[0056] Step 2: At this time, the motor 5001 in the driving mechanism 5 starts to rotate, and the rotation of the motor 5001 will drive the rotation of the first transmission shaft 5002, and the rotation of the first transmission shaft 5002 will drive the rotation of the first sc...

Embodiment 3

[0064] First turn on the power, so that the whole building steel bar straightening device starts to run, then press the first button 10 to allow the transmission mechanism 2 and the drive mechanism 5 to start running, then the steel bar is placed on the conveyor belt 2002, at this time, the fifth pulley 2001 And the sixth pulley 2003 starts to roll, and along with the rotation of the fifth pulley 2001 and the sixth pulley 2003, it will drive the rotation of the conveyor belt 2002, and the conveyor belt 2002 has played the role of conveying steel bars, and the rotation of the conveyor belt 2002 will allow the steel bars to pass through the feed The port 16 enters the delivery box 15; at this time, the motor 5001 in the driving mechanism 5 starts to rotate, and the rotation of the motor 5001 will drive the rotation of the first transmission shaft 5002, and the rotation of the first transmission shaft 5002 will drive the first rolling wheel 5003 The rotation of the rolling belt 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com