Positioning claw cutting feeding device

A technology of feeding device and positioning claw, which is applied in the direction of conveyor objects, transportation and packaging, assembly/disassembly of contact parts, etc., and can solve the problems of unable to meet the assembly requirements of positioning claws and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

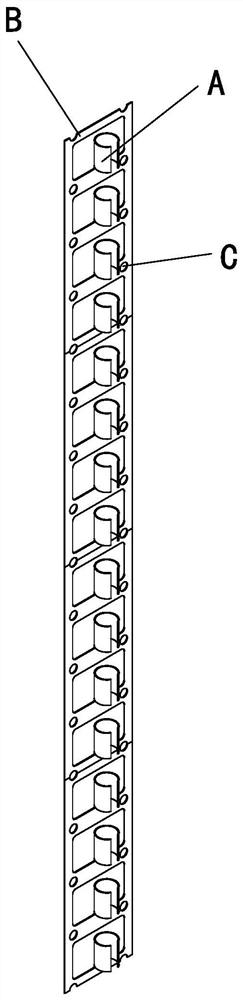

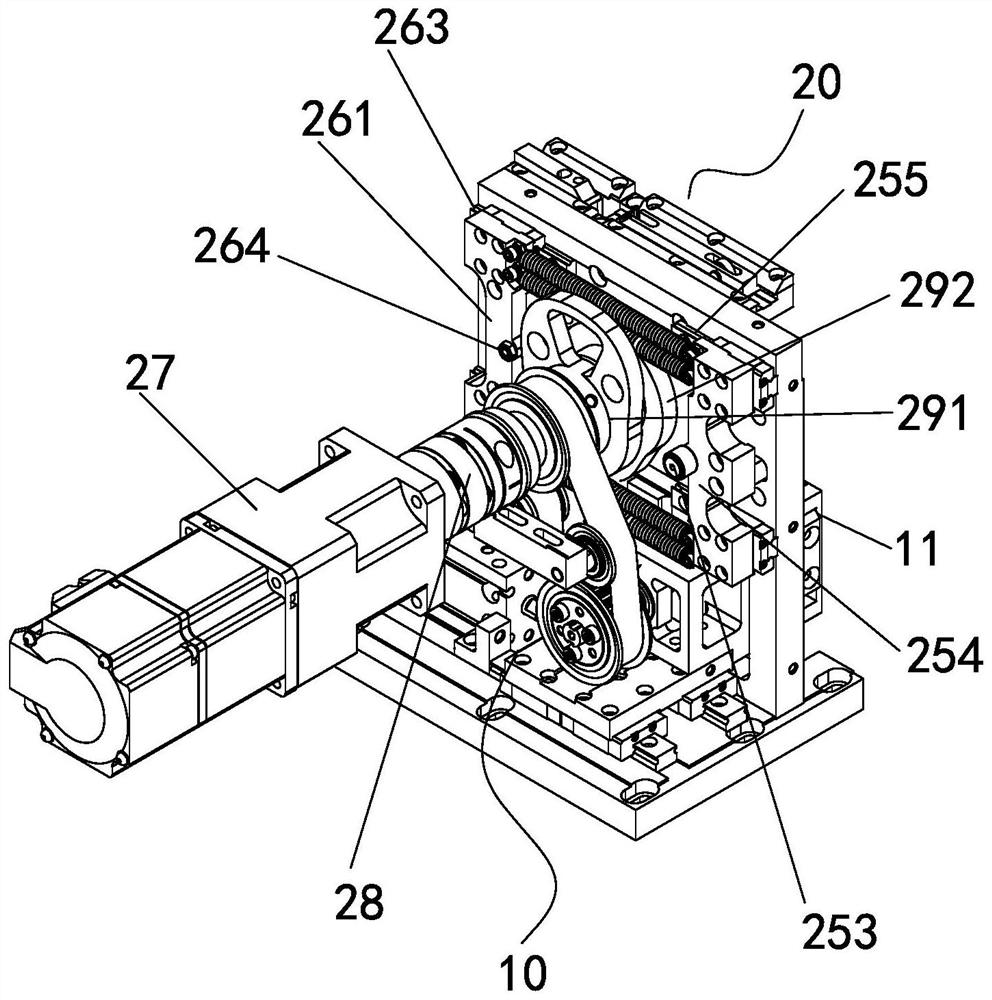

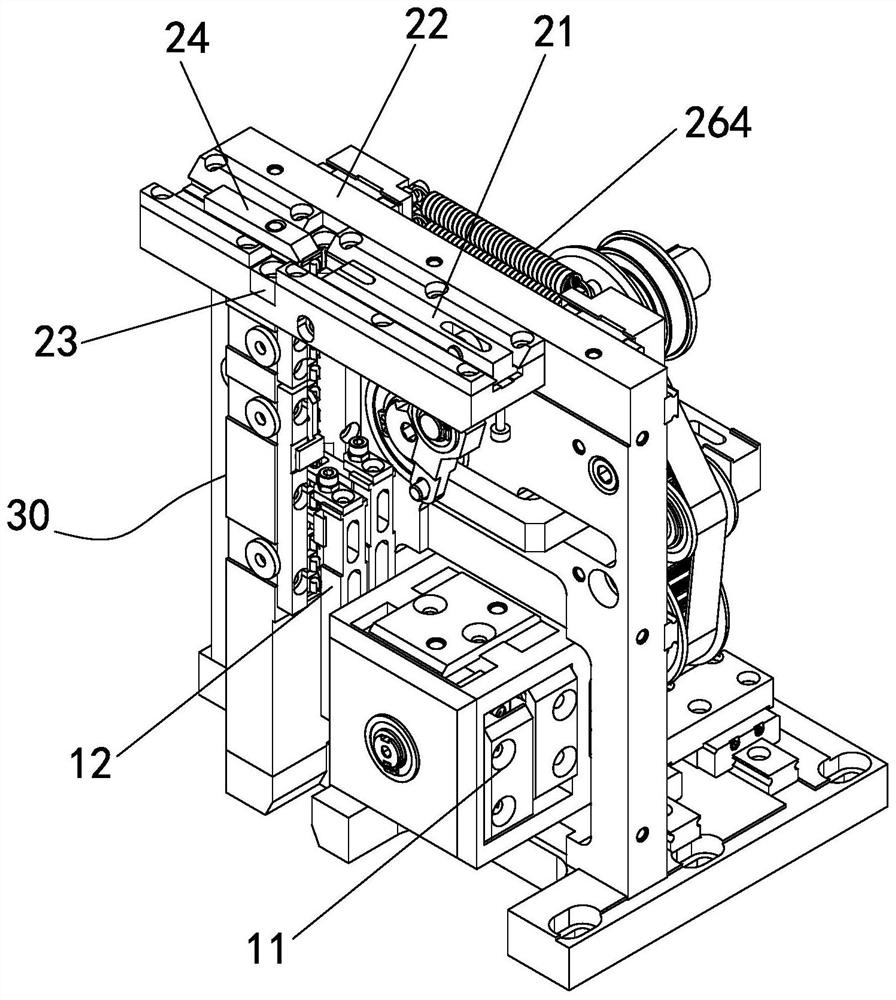

[0019] A positioning claw cutting and feeding device, comprising a material belt lifting mechanism 10, a material head side pushing cutting mechanism 20 and a material belt guiding mechanism 30, the material head side pushing and cutting mechanism 20 is located above the material belt guiding mechanism 30, and the material belt The guiding mechanism 30 is located beside the strip guiding mechanism 30 . The material head side pushing and cutting mechanism 20 includes a side pushing block 21, a guide block 22, a lining block 23, a limit block 24, a power transmission component 1 25, a power transmission component 2 26 and a servo reduction motor 27, and the guide block 22 is arranged horizontally. The lining block 23 is fixed in the guide block 22, the side pushing block 21 and the limiting block 24 are slidably connected in the guiding block 22, and are respectively located on both sides of the lining block 23, and the side pushing block 21 is arranged on one side corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com