A kind of silicon carbide composite powder and its preparation method and use

A technology of carbon silicon carbide and composite powder, which is applied in the field of carbon silicon carbide composite powder and its preparation, can solve the problems of difficulty in forming carbon silicon carbide composite powder, low yield of carbon silicon carbide target material, and poor performance such as density, etc., to achieve Excellent formability, good fluidity, and the effect of weakening lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

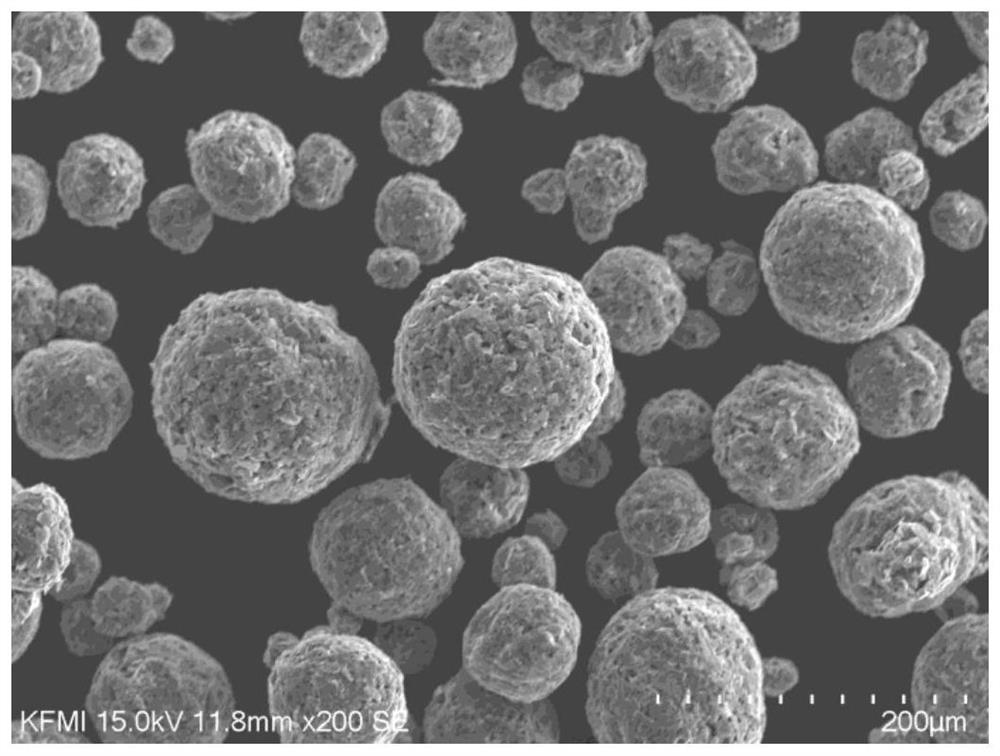

Image

Examples

Embodiment 1

[0065] This embodiment provides a preparation method of silicon carbide composite powder, and the preparation method includes the following steps:

[0066] (1) Prepare carbon powder and silicon carbide powder according to the target mass ratio, and mix them uniformly by ball milling to obtain carbon silicon carbide mixed powder;

[0067] Wherein, the particle size of the carbon powder is less than 20 μm, the particle size of the silicon carbide powder is less than 10 μm, the carbon powder is high-purity carbon powder with a purity of 99.995wt%, and the silicon carbide powder is a high-purity carbon powder with a purity of 99.9wt% Silicon powder, the proportion of carbon powder in the target mass ratio is 50wt%, and the rest is silicon carbide powder and inevitable impurities; the material-to-ball ratio of the ball mill is 2:1, and the ball milling time is 30h , the ball-milling medium of the ball-milling is silicon carbide balls, and the ball-milling is carried out under seali...

Embodiment 2

[0073] This embodiment provides a preparation method of silicon carbide composite powder, and the preparation method includes the following steps:

[0074] (1) Prepare carbon powder and silicon carbide powder according to the target mass ratio, and mix them uniformly by ball milling to obtain carbon silicon carbide mixed powder;

[0075]Wherein, the particle size of the carbon powder is less than 20 μm, the particle size of the silicon carbide powder is less than 10 μm, the carbon powder is high-purity carbon powder with a purity of 99.995wt%, and the silicon carbide powder is a high-purity carbon powder with a purity of 99.9wt% Silicon powder, the proportion of carbon powder in the target mass ratio is 40wt%, and the rest is silicon carbide powder and inevitable impurities; the material-to-ball ratio of the ball mill is 1:1, and the ball milling time is 24h , the ball-milling medium of the ball-milling is silicon carbide balls, and the ball-milling is carried out under sealin...

Embodiment 3

[0080] This embodiment provides a preparation method of silicon carbide composite powder, and the preparation method includes the following steps:

[0081] (1) Prepare carbon powder and silicon carbide powder according to the target mass ratio, and mix them uniformly by ball milling to obtain carbon silicon carbide mixed powder;

[0082] Wherein, the particle size of the carbon powder is less than 20 μm, the particle size of the silicon carbide powder is less than 10 μm, the carbon powder is high-purity carbon powder with a purity of 99.995wt%, and the silicon carbide powder is a high-purity carbon powder with a purity of 99.9wt% Silicon powder, the proportion of carbon powder in the target mass ratio is 60wt%, and the rest is silicon carbide powder and inevitable impurities; the material-to-ball ratio of the ball mill is 3:1, and the ball milling time is 36h , the ball-milling medium of the ball-milling is silicon carbide balls, and the ball-milling is carried out under seali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com