Thermoplastic nylon elastomer containing pyrrolidone structure amorphous nylon segment and its preparation method and application

A nylon elastomer and pyrrolidone technology is applied in the field of thermoplastic nylon elastomer and its preparation, which can solve the problems of endangering the life safety of operators, difficulty in reaction operation, and high post-processing cost, and achieves wide application range and excellent thermal stability. , the effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

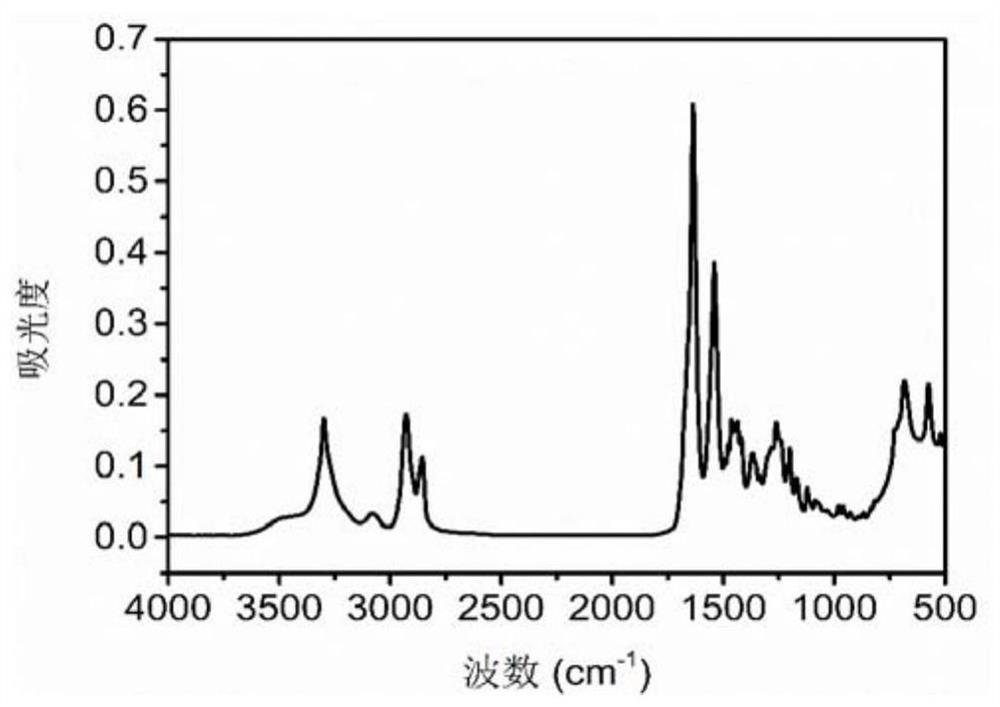

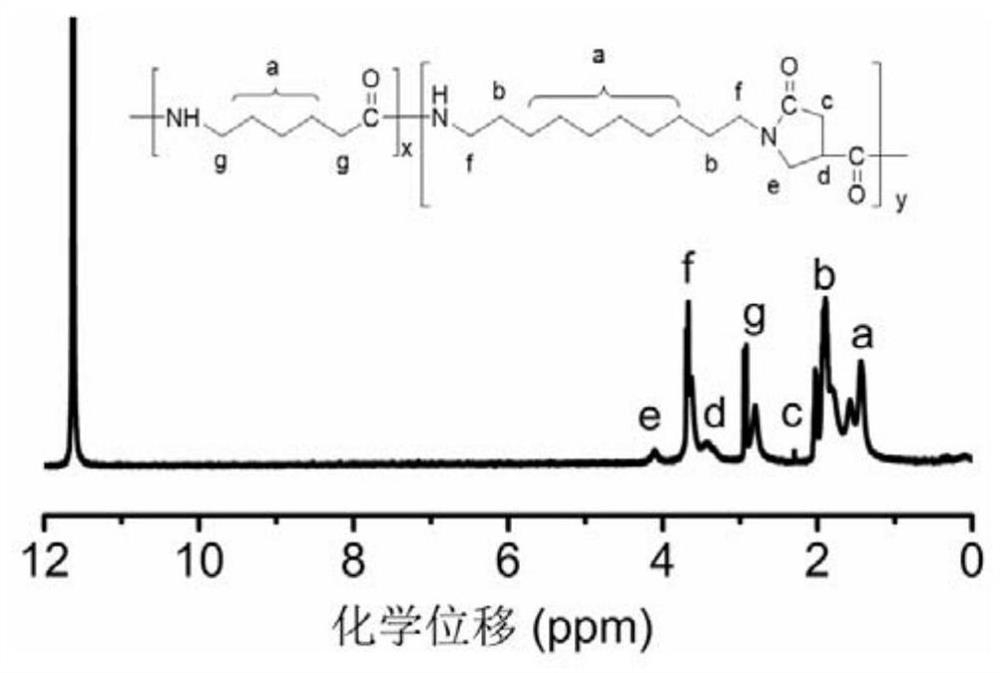

Method used

Image

Examples

Embodiment 1

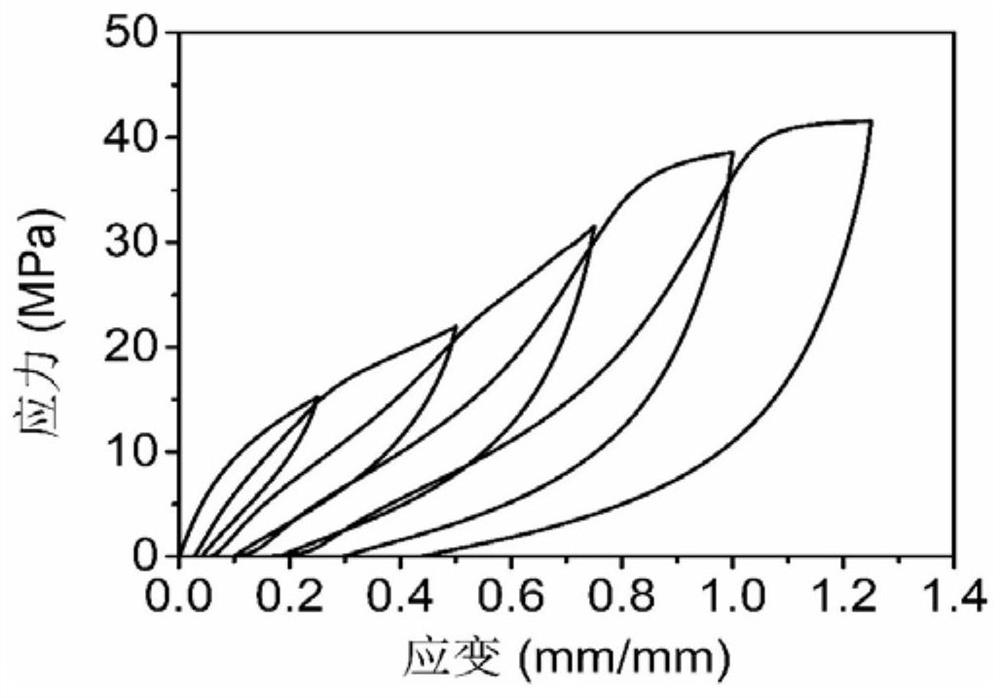

[0048] 56.58g of caprolactam, 30.24g of nylon salt formed by the equimolar reaction of itaconic acid and decyl diamine and 2.42g of hydroquinone / sodium hypophosphite aqueous solution with a mass fraction of 2.0% were added to the polymerization vessel, and successively Raise the temperature to 200°C for 1 hour, 220°C for 4 hours, 240°C and vacuum to below 2000Pa for 2.5 hours.

[0049] The intrinsic viscosity [η] of the thermoplastic nylon elastomer is 1.35dL / g, the elongation at break and the tensile strength are 374% and 31.78MPa, respectively, the light transmittance is 73.7%, and the water absorption rate is 7.58%.

Embodiment 2

[0051] Add 45.26g of caprolactam, 30.24g of itaconic acid and the nylon salt formed by the equimolar reaction of decyl diamine and 2.42g of hydroquinone / sodium hypophosphite aqueous solution with a mass fraction of 2.0% into the polymerization vessel, and sequentially Raise the temperature to 200°C for 1 hour, 220°C for 3 hours, 240°C and vacuum to below 2000Pa for 2.5 hours.

[0052] The intrinsic viscosity [η] of the thermoplastic nylon elastomer is 1.3dL / g, the elongation at break and the tensile strength are 544% and 26.39MPa, respectively, the light transmittance is 75.9%, and the water absorption is 6.01%.

Embodiment 3

[0054] Add 22.63g of caprolactam, 60.48g of itaconic acid and nylon salt formed by the equimolar reaction of decyl diamine and 3.02g of hydroquinone / sodium hypophosphite aqueous solution with a mass fraction of 2.0% into the polymerization vessel, and sequentially Raise the temperature to 200°C for 1 hour, 215°C for 5 hours, 225°C and vacuum to below 2000Pa for 1 hour.

[0055] The intrinsic viscosity [η] of the thermoplastic nylon elastomer is 1.72dL / g, the elongation at break and the tensile strength are 764% and 11.27MPa, respectively, the light transmittance is 80.0%, and the water absorption is 8.24%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com