1000MPa cold-rolled dual-phase steel with excellent local forming performance and preparation method thereof

A formability, dual-phase steel technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve problems such as poor phosphating, achieve the effects of reducing the hardness difference between the two phases, refining grains, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

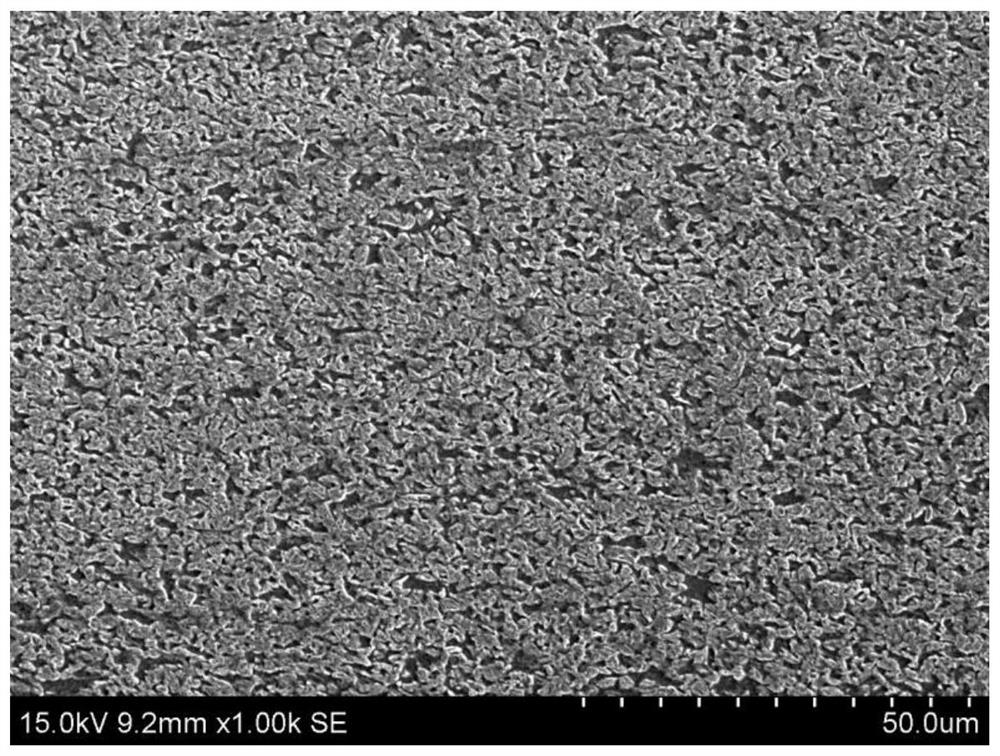

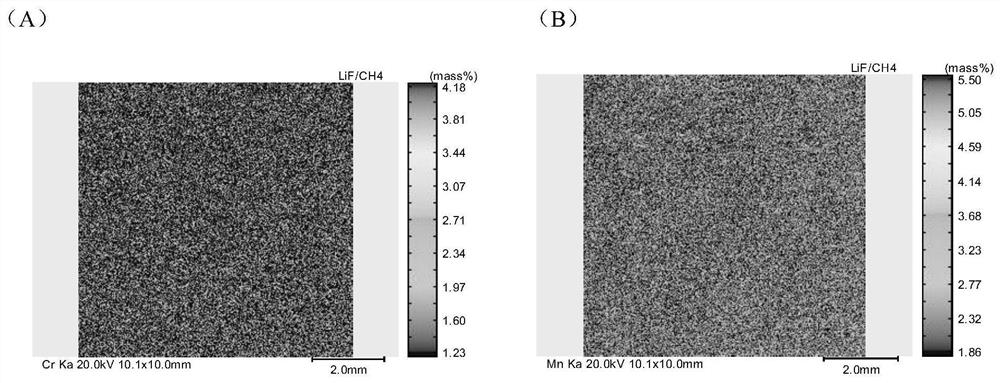

Image

Examples

preparation example Construction

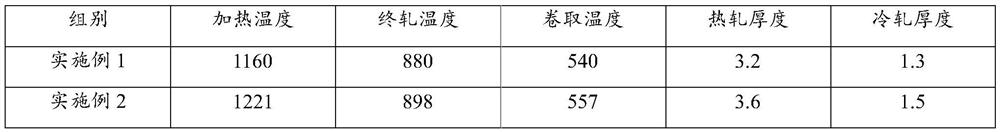

[0046] According to another typical embodiment of the present invention, a preparation method of the 1000MPa cold-rolled dual-phase steel with excellent local formability is provided, the preparation method comprising:

[0047] Using the chemical composition of the 1000MPa cold-rolled dual-phase steel with excellent local formability to melt and forge to obtain a billet;

[0048] Heating the billet before rolling, rough rolling, finish rolling and coiling to obtain a hot-rolled plate;

[0049] cold-rolling the hot-rolled plate to obtain a chilled steel strip;

[0050] Annealing the chilled steel strip to obtain an annealed steel plate; the annealing includes a heating section, a soaking section, a slow cooling section and a fast cooling section, and the heating section is from room temperature at 0.9°C / s to 21°C / s The rate is heated to 780 ℃ ~ 835 ℃; the atmosphere of the soaking section adopts N 2 -H 2 mixed gas, the H 2 The content is 5% to 15%, the soaking temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com