A kind of sodium bentonite type foamed ceramic body, sodium bentonite type foamed ceramic tile and preparation method thereof

A technology of sodium-based bentonite and foamed ceramics, applied in ceramic products, ceramic molding machines, manufacturing tools, etc., can solve the problems of high strength, low bulk density, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

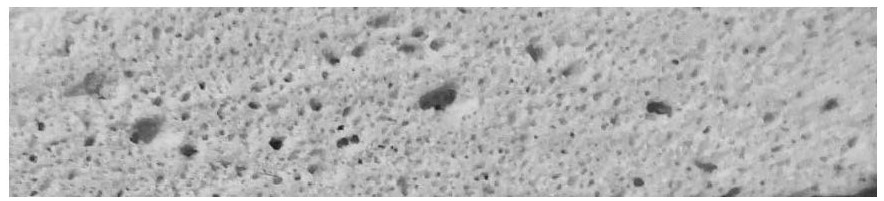

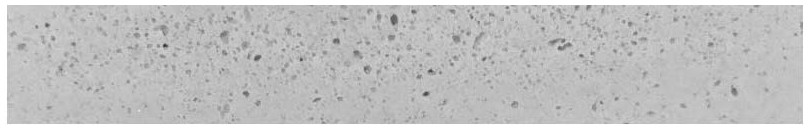

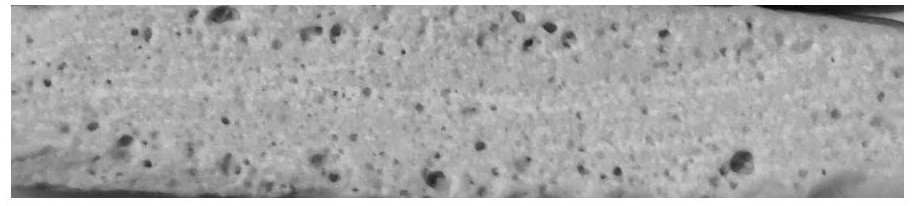

Image

Examples

Embodiment 1

[0052] 1. Prepare the green body powder. The raw material formula composition of the green body powder includes, in terms of mass percentage, including: Lihong sand 10%, Lingwu sand 5%, sodium bentonite 12%, 4# mud 10%, double cement 8%, Zhongshan black Mud 3%, filter press residue 50%, limestone 2%. Add reinforcing agent 0.15%, silicon carbide 0.20%. The chemical composition of the green body includes: by mass percentage, SiO 2 67.63%, Al 2 O 3 18.63%, Fe 2 O 3 0.94%, TiO 2 0.31%, CaO 1.93%, MgO 0.70%, K 2 O 2.34%, Na 2 O1.82%, burning loss 4.81%.

[0053] Weigh each raw material according to the above ratio, put it into a ball mill for ball milling to obtain a slurry, and spray the slurry with a spray tower to obtain a green body powder. The moisture content of the green powder is 7.2-7.8 wt%. The particle gradation of the green powder is: in terms of mass percentage, 12~18% above 30 mesh, 30~60 mesh ≥70%, 60~80 mesh ≤8%, and below 80 mesh <6%.

[0054] 2. Press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com