Method for preparing diamond by multi-energy coupling plasma chemical vapor deposition method

A technology of chemical vapor deposition and coupled plasma, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of uncoupling energy, parameter fluctuations, and more stringent requirements for process parameters, etc., and achieve control The effect of high tolerance, reduced control requirements, and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

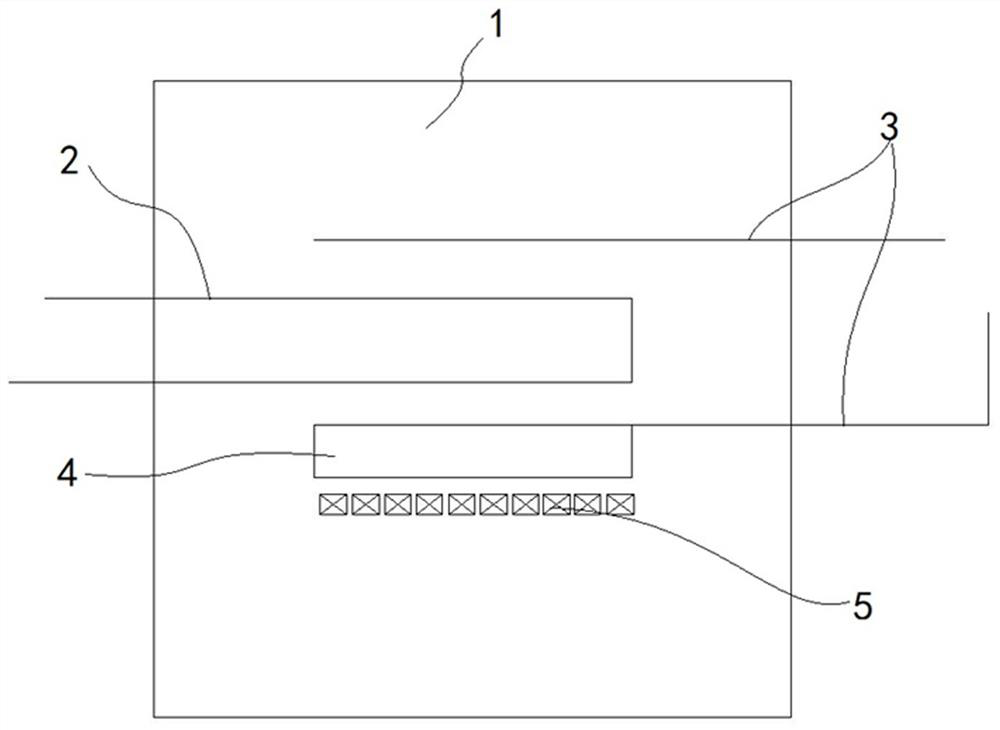

Image

Examples

Embodiment 1 to 6

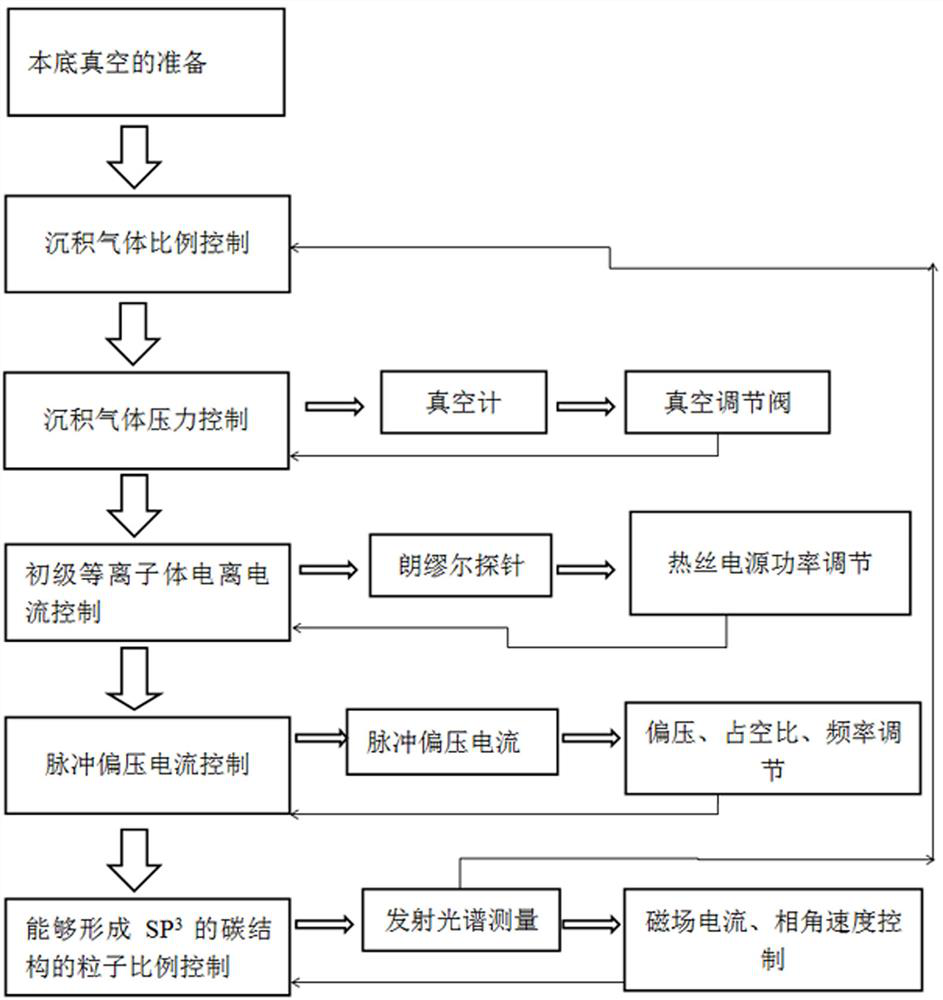

[0088] The preparation procedures of Examples 1 to 6 are as follows, and the parameters in the preparation process are shown in Table 1.

[0089] (1) Background vacuum preparation;

[0090] (2) Deposition gas ratio control;

[0091] (3) Control of the vacuum degree of the deposition chamber;

[0092] (4) Setting of heating wire power supply and ionization current setting value;

[0093] (5) The power of the pulse bias power supply is set to 5kW, and the duty cycle, frequency, bias voltage and pulse bias current setting value of the pulse bias power supply are set;

[0094] (6) Set the power of the rotating magnetic field to 10, and set the magnetic field strength and rotational angular velocity of the rotating magnetic field;

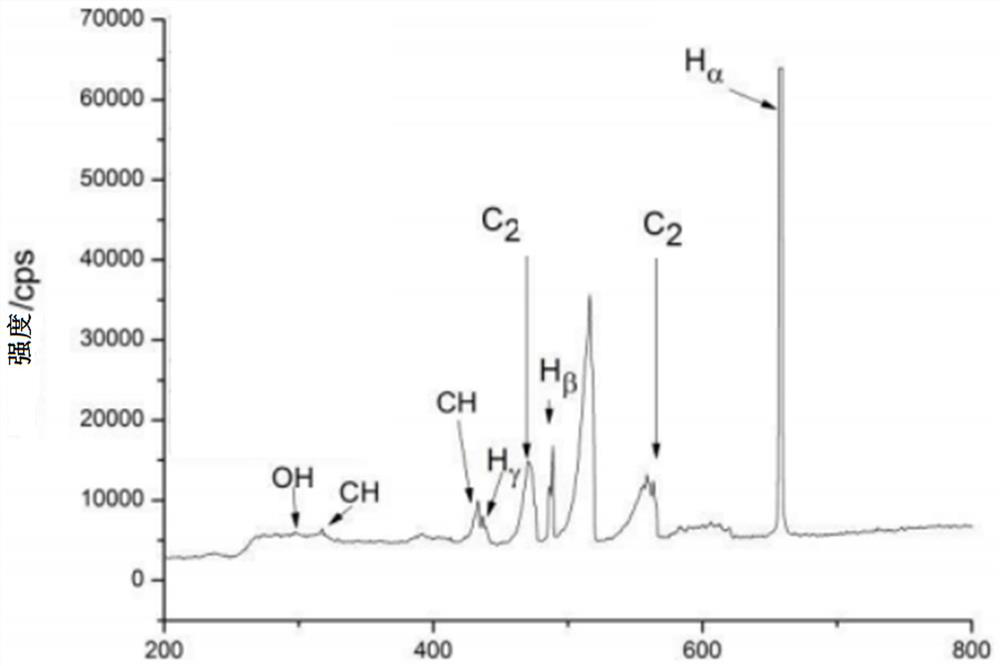

[0095] (7) During the deposition process, when the deviation between the ionization current detected by the Langmuir probe and the set value of the ionization current is ≥ 2%, the power of the heating wire power supply should be adjusted up or down a...

Embodiment 1

[0102] The flatness of the diamond prepared by the method of Example 1 is about 0.1%, and the area of the diamond is 200mm×200mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap