Preparation method of high-filling-power warm-keeping down feather

A technology with high bulkiness and down, which is applied in dyeing, textile and papermaking, fiber treatment, etc. It can solve the problems of reduced service life and insufficient protection of down and down, and achieve a long shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

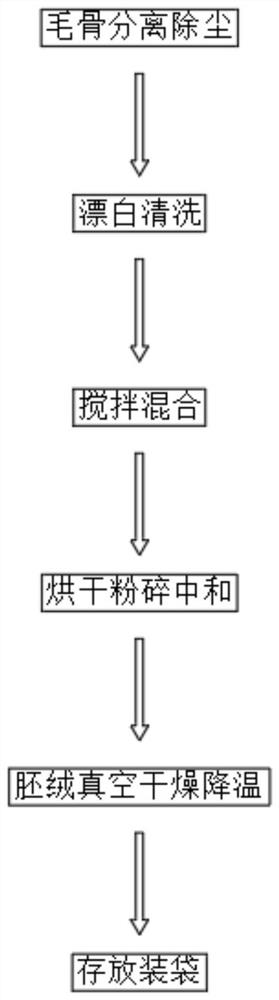

Image

Examples

Embodiment 1

[0025] Embodiment 1: A method for preparing warm down with high bulkiness, including step 1: firstly separate the feathers and feather bones of goose feathers and duck feathers, and then the staff can take out the separated feathers for color separation and screening, and separate the feathers The light-colored feathers are screened out, then the feathers screened out are placed on the deashing device, the sandstone remaining on the feathers is separated from the feathers, and 10 kg of feathers that are removed from the feathers are taken out;

[0026] Step 2: Take out the feathers treated in step 1 and put them in the cleaning device, and put 10g of bleaching agent in the cleaning device, and then select the feathers that have not turned white from the cleaned feathers. Place these unbleached feathers and 1g of bleaching agent into the inside of the cleaning device for secondary cleaning;

[0027] Step 3: Take out the feathers bleached in step 2 and place them inside the stir...

Embodiment 2

[0039] A method for preparing warm down with high bulkiness, comprising

[0040] Step 1: First separate the feathers and feather bones of goose feathers and duck feathers, and then the staff can take out the separated feathers for color separation and screening, and filter out the light-colored feathers from the separated feathers, and then place the screened feathers Go to the deashing device, separate the sand and gravel remaining on the feathers from the feathers, and take out 10kg of the feathers that have been deashed;

[0041] Step 2: Take out the feathers treated in step 1 and put them in the cleaning device, and put 10g of bleaching agent in the cleaning device, and then select the feathers that have not turned white from the cleaned feathers. Place these unbleached feathers and 1g of bleaching agent into the inside of the cleaning device for secondary cleaning;

[0042]Step 3: Take out the feathers bleached in step 2 and place them inside the stirring device, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com