A construction method for a pipe-free and protective integrated check dam

A construction method and technology of check dams, applied in the field of check dam construction, can solve problems such as large number of check dams, low flood control standards, and increased project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

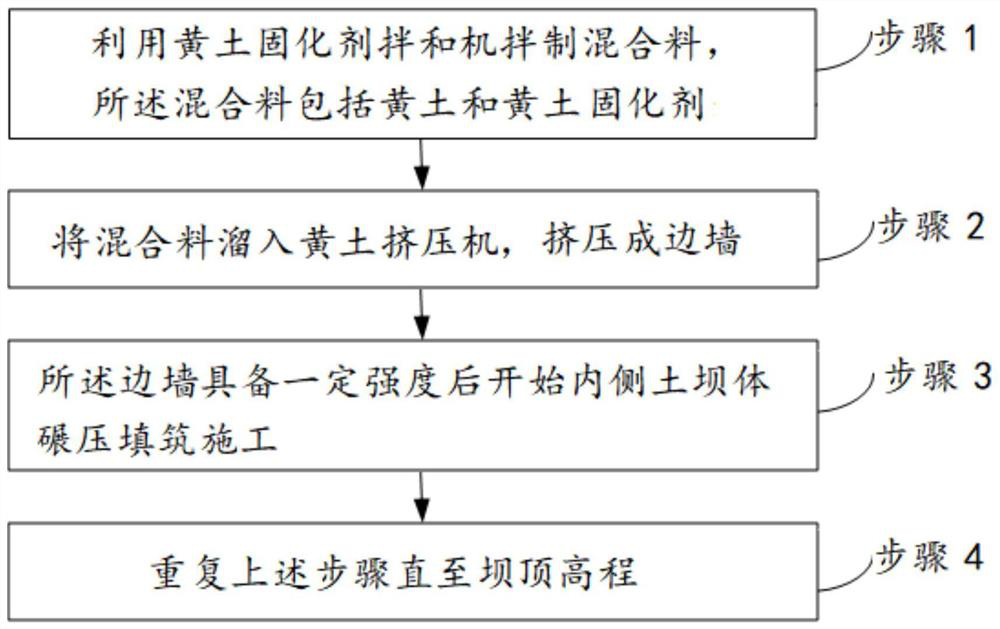

[0071] Embodiments of the present invention provide a construction method for a pipe-free and protective integrated check dam, such as Figure 1-5 shown, including the following steps:

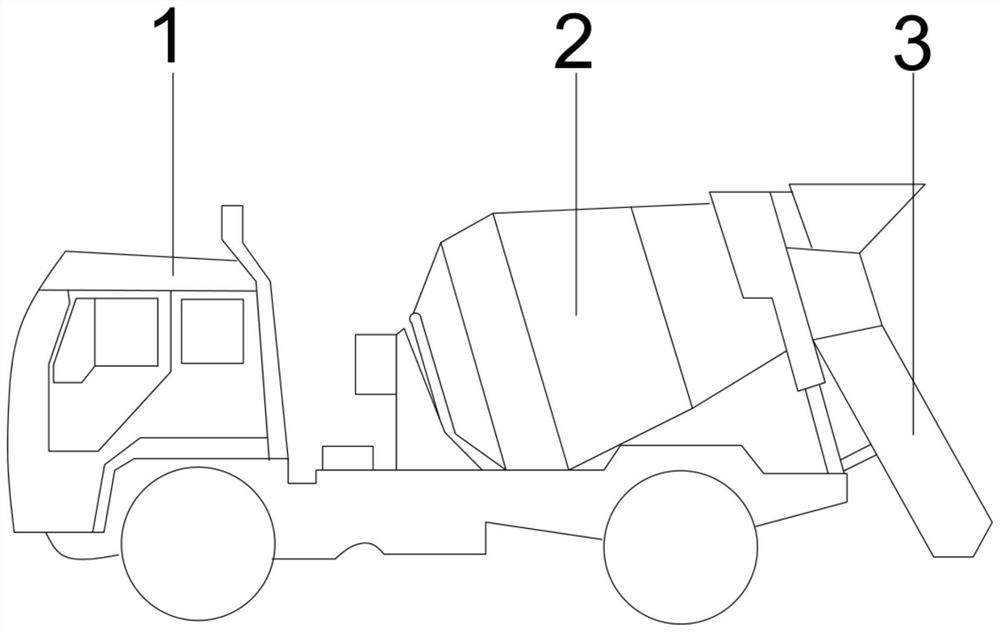

[0072] Step 1: utilize the forced mixer 2 and the loess curing agent mixing machine (the loess curing agent mixing machine (seeing for reference) of flat car 1 refitting figure 2 ) includes: a flat car, the flat car is equipped with a forced mixer, the discharge port of the forced mixer is provided with a chute, and after mixing, the mixed material is put into the warehouse through the chute to the loess extruder) mixing the mixture;

[0073] Preferably, specifically: put the loess and the loess curing agent invented by YREC (refer to Chinese patent document CN201811405697) into the loess curing agent mixer according to the ratio of 70-90:10-30 by weight, and stir for 90-120s , so that the two are fully mixed evenly. The two materials are evenly mixed by a forced mixer, so that the formed ...

Embodiment 2

[0085] On the basis of above-mentioned embodiment 1, as Image 6 As shown, the small compaction equipment includes a small ramming device, and the small ramming device includes:

[0086] The first housing 43, the left side of the upper end of the first housing 43 is provided with a slide groove 1 4301, the right side of the lower end of the first housing 43 is provided with a lifting groove 4302, and the left side of the lower end of the first housing 43 is Four wheels 47 are arranged, the upper end of the first housing 43 is provided with a hydraulic cylinder 49, and the left side of the first housing 43 is provided with a push handle 41;

[0087] Sliding block 57, said sliding block 57 is fixedly connected with the telescopic rod of said hydraulic cylinder 49, said sliding block 57 runs through said sliding groove 4301 and is slidably connected in the horizontal direction, said sliding block 57 lower end right side is connected with connecting block Two 56 are fixedly conne...

Embodiment 3

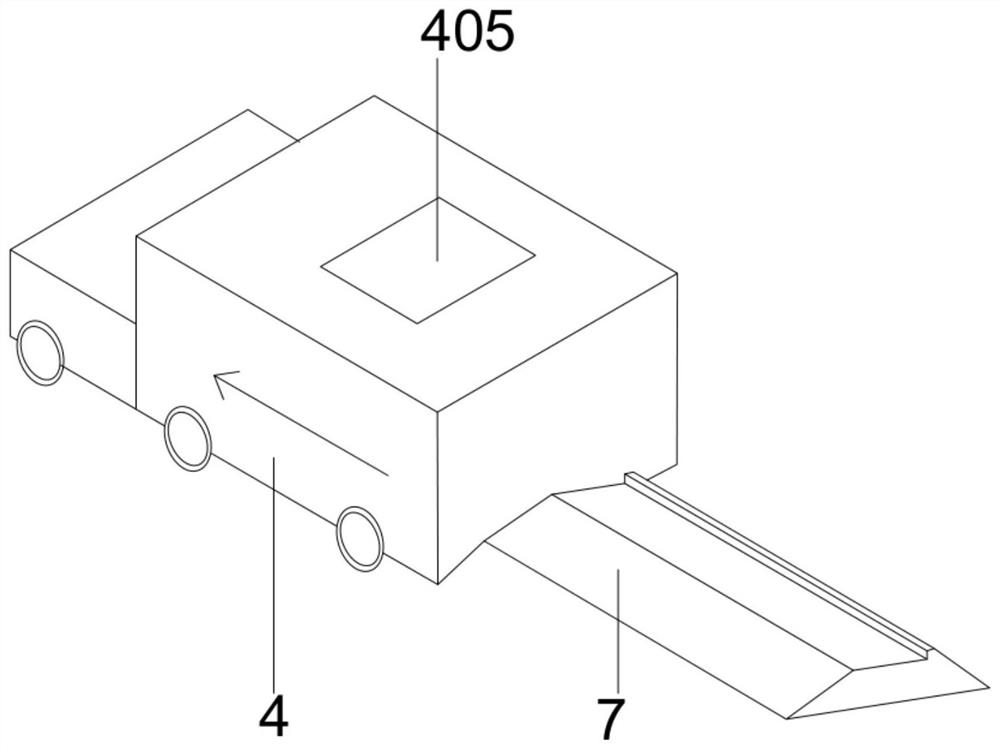

[0093] On the basis of above-mentioned embodiment 1 or 2, as Figure 7 ~ Figure 11 As shown, the upper end of each layer of the anti-scouring protective layer 7 is provided with a waterproof groove 8 near the side of the homogeneous earth dam 9, and the loess extruder 4 includes:

[0094] Second housing 6: the inside of the second housing 6 is provided with a first cavity 401, a second cavity 402, and a mounting groove 403 in sequence from right to left, and between the second cavity 402 and the mounting groove 403 A partition 406 is provided, the lower end of the partition 406 is provided with a delivery port 404, the installation groove 403 communicates with the second cavity 402 through the delivery port 404, and the upper end of the second housing 6 is provided with a feed port 405, the feed port 405 communicates with the second cavity 402, the second cavity 402 does not communicate with the first cavity 401, the first cavity 401 is provided with a power device inside, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com