Gridding cemented riprap anti-scouring structure

A gridded, anti-scour technology, applied in infrastructure engineering, construction, installation/support of wind turbine configuration, etc., can solve problems such as poor anti-scour effect, and reduce the amount of riprap, the depth and scope of the scour pit The effect of reducing and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

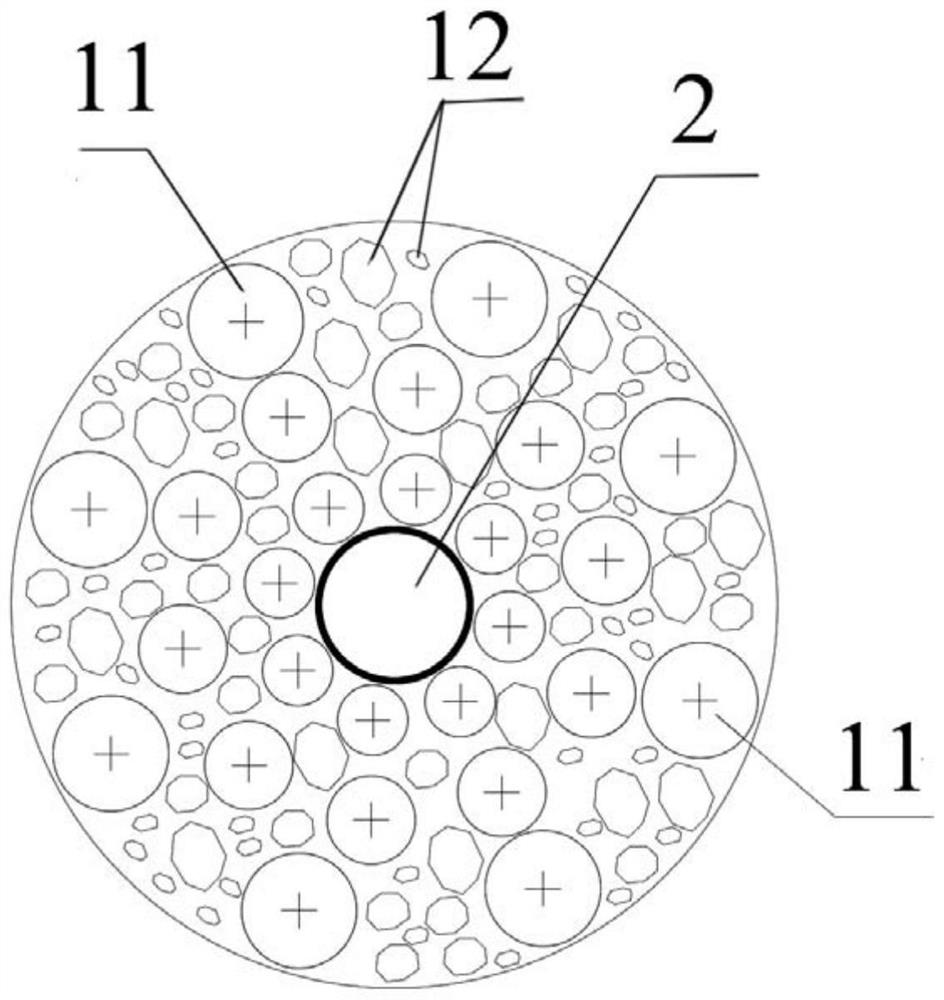

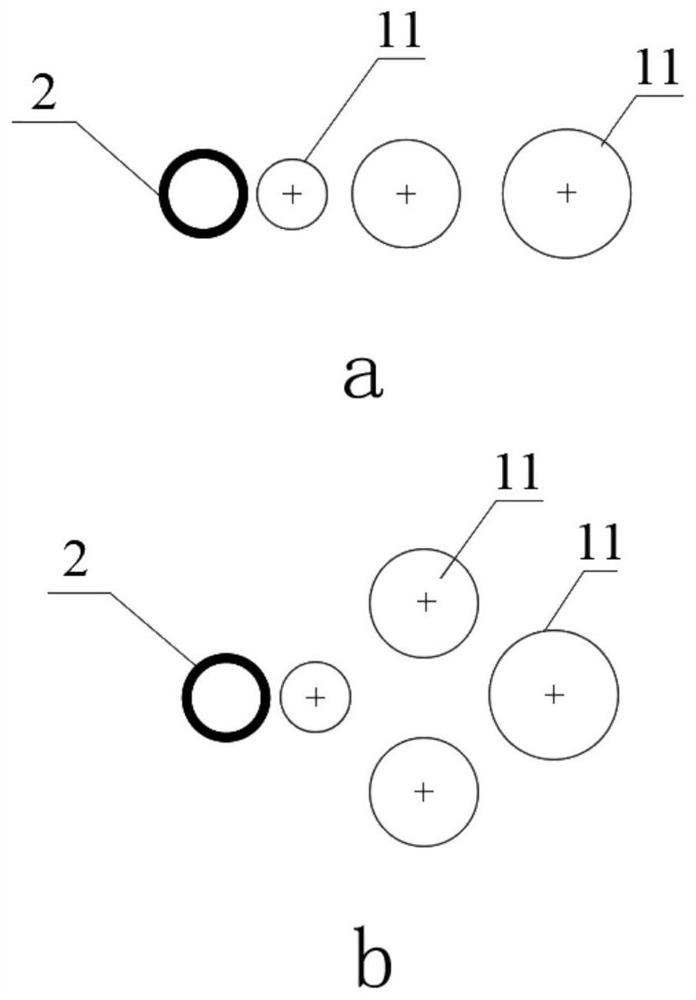

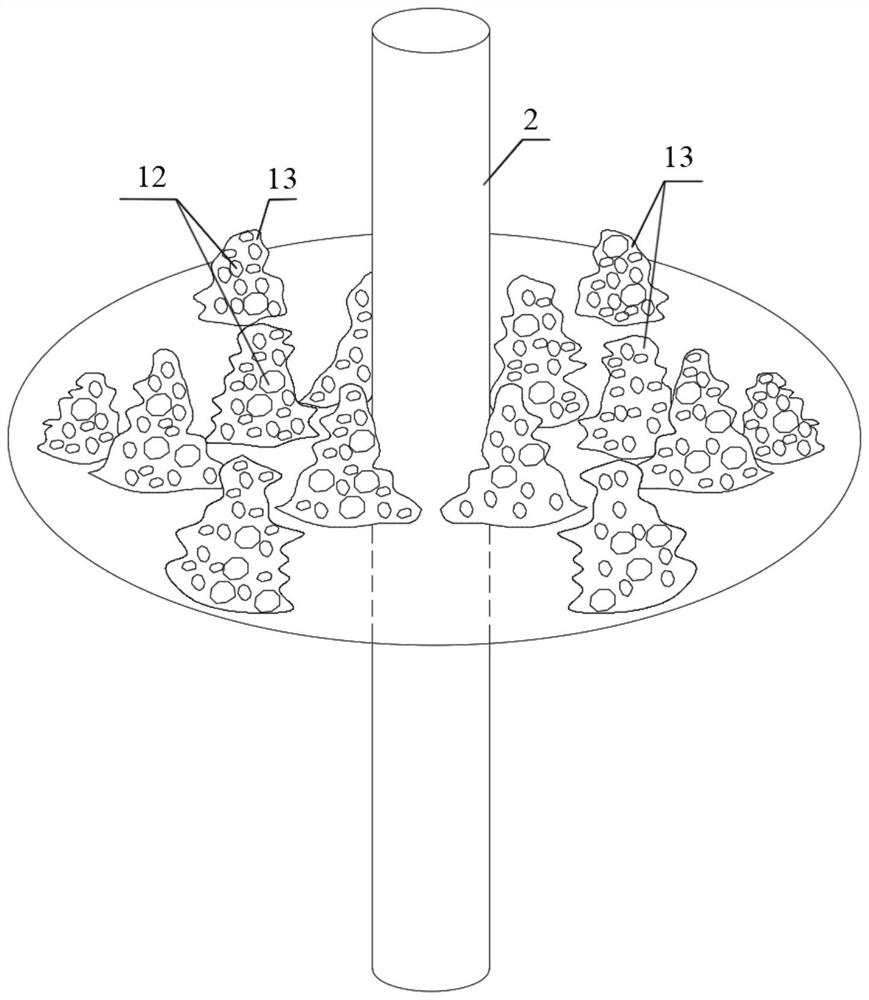

[0042] A gridded cemented riprap anti-scouring structure, such as Figure 1-Figure 3 As shown, it includes: riprap particles 12, uniformly distributed around the periphery of the structure 2; gel 13, filled between the riprap particles 12 to connect part of the riprap particles 12 from top to bottom to form a cemented stalagmite 11: There are several cemented stalagmites 11 distributed around the structure 2 in a grid pattern, and the cemented stalagmites 11 have a structure of small top and large bottom, and the periphery of cemented stalagmites 11 is surrounded by riprap particles 12 .

[0043] A gridded cemented riprap anti-scouring structure provided by the present invention is composed of cemented stalagmites 11 and surrounding riprap particles 12, wherein the cemented stalagmites 11 are used as the core structure to play the role of rigid skeleton support and effectively resist wave water erosion , and ensure the stability of the surrounding riprap particles 12; as an au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com