Natural tobacco leaf brittleness detection method

A detection method and technology for tobacco leaves, which can be applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as large errors in the brittleness detection of natural tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

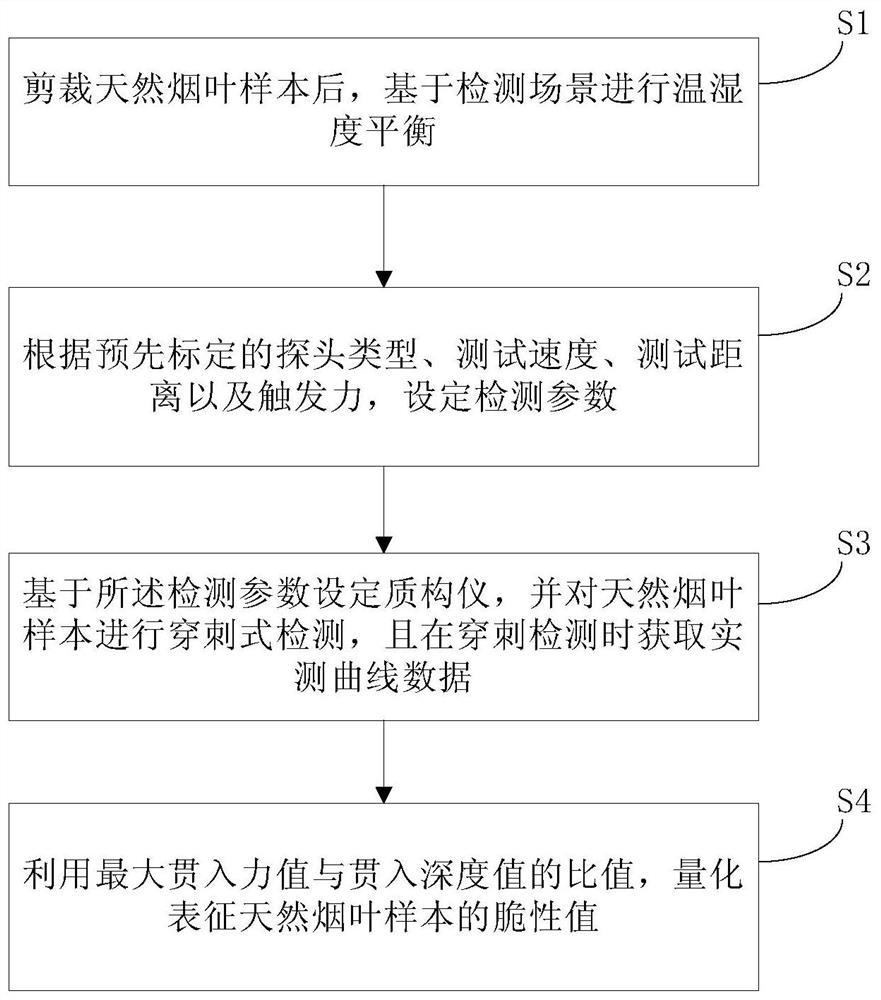

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

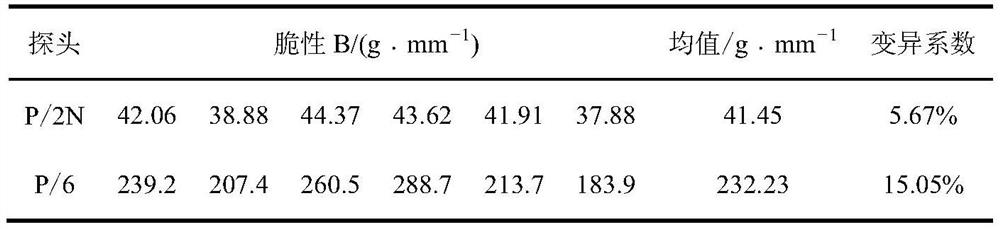

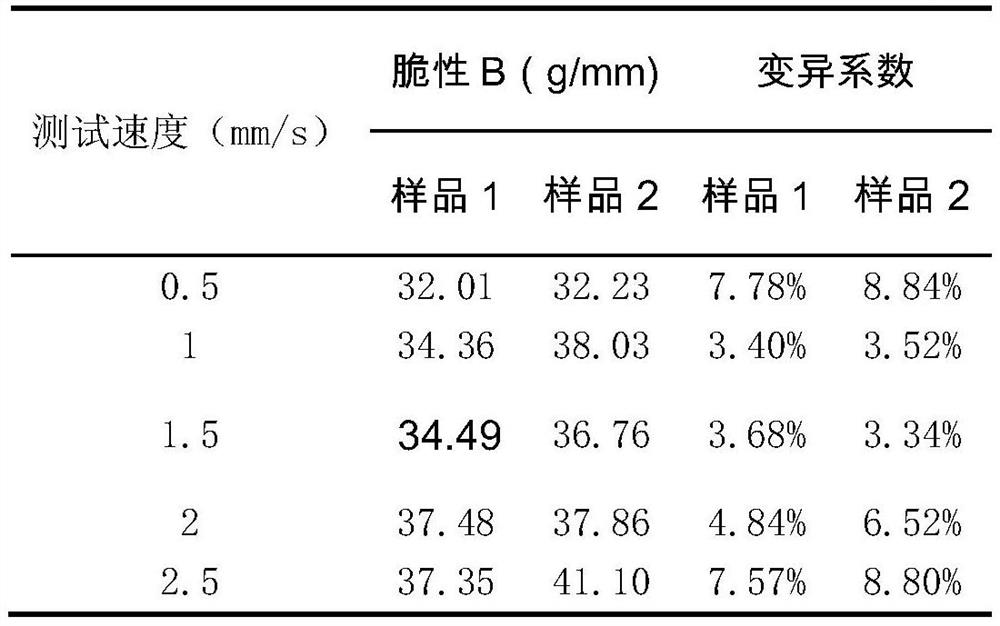

[0026] In view of the disadvantages of the existing detection methods mentioned above, the inventor believes that it is necessary to abandon the conventional detection ideas, and thus proposes a method embodiment of using a texture analyzer to detect the brittleness of natural tobacco leaves, wherein the texture The instrument, also known as the physical characteristic tester, mainly detects and analyzes samples by simulating the human sense of touch. It is an accurate sensory quantitative testing instrument. Its operation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com