AC injection insulation resistance detection circuit and method

An insulation resistance and AC injection technology, applied in the field of AC injection insulation resistance detection circuits, can solve the problems of deviation in the calculation of turning points, affecting the accuracy of the detection circuit, and inconspicuous turning points, etc., to ensure the accuracy of voltage sampling, speed up the discharge speed, avoid The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

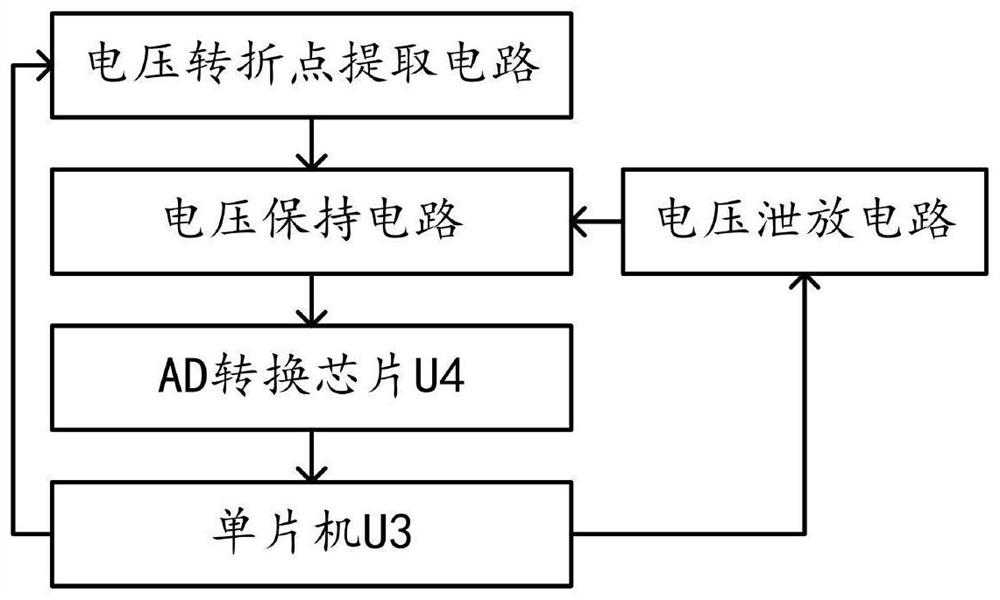

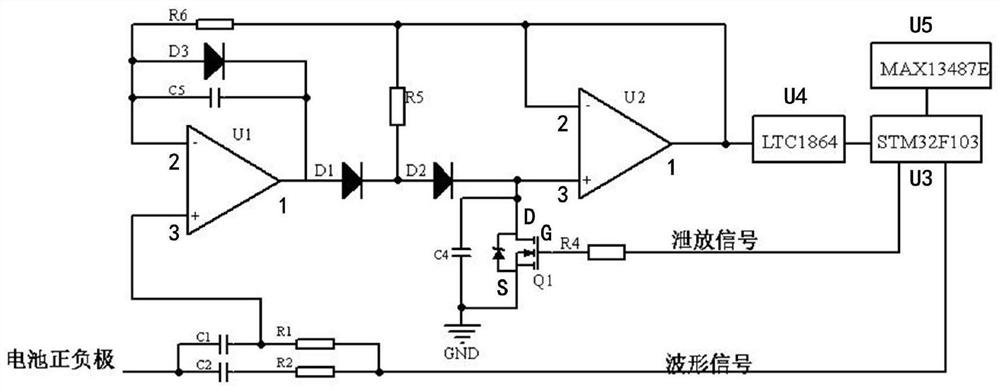

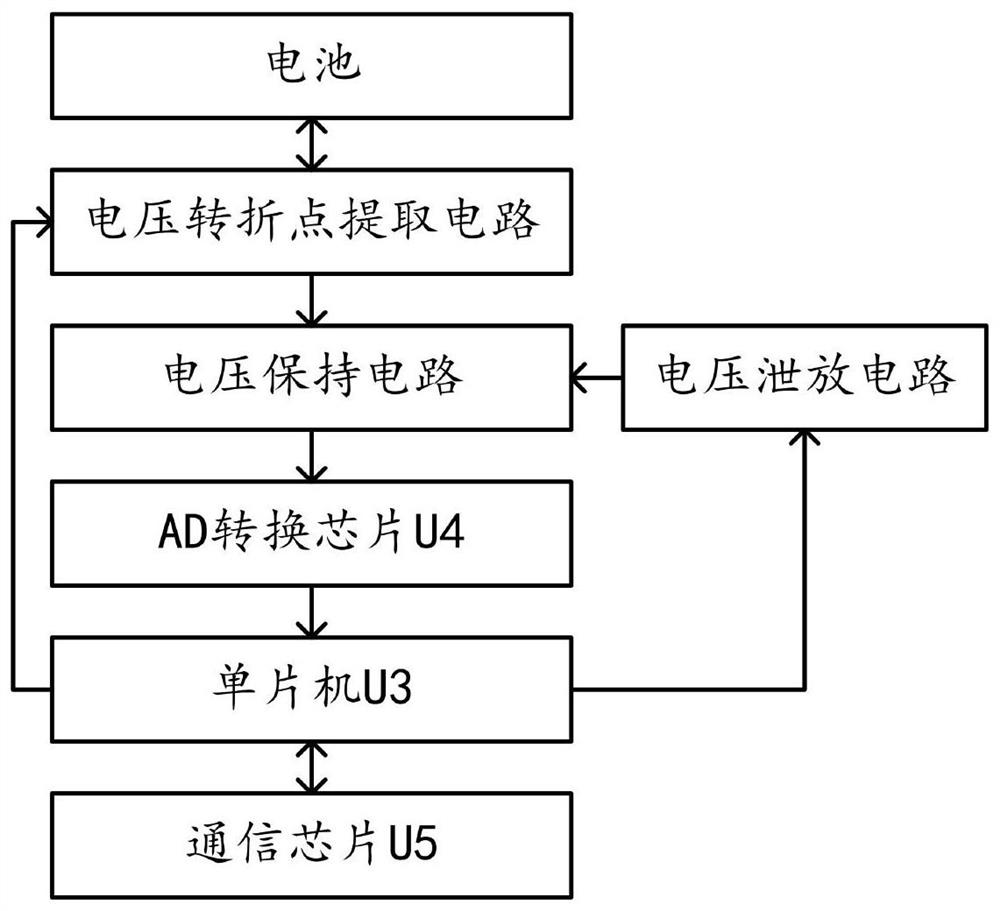

[0056] The general idea of the technical solution in the embodiment of the present application is as follows: by setting the voltage turning point extraction circuit, the curve fitting evaluation is changed into a sampling scheme of taking the maximum value in the interval, reducing the difficulty of sampling the turning voltage of the voltage turning point, and improving the sampling efficiency. Accuracy; by setting the voltage holding circuit to perform voltage holding operation on the turning voltage (peak voltage) generated by the voltage turning point extraction circuit, the voltage sampling accuracy of the AD conversion chip U4 is guaranteed, and the requirement for AD sampling speed is reduced; by setting the voltage discharge circuit The voltage of the capacitor C4 in the voltage holding circuit is discharged to speed up the discharge speed, so as to improve the accuracy and speed of the insulation resistance detection.

[0057] Please refer to Figure 1 to Figure 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com