Optical element unit

A technology of optical components and optical systems, applied in the direction of optical components, optics, connecting components, etc., can solve problems such as a large amount of time and easy enlargement of laser processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

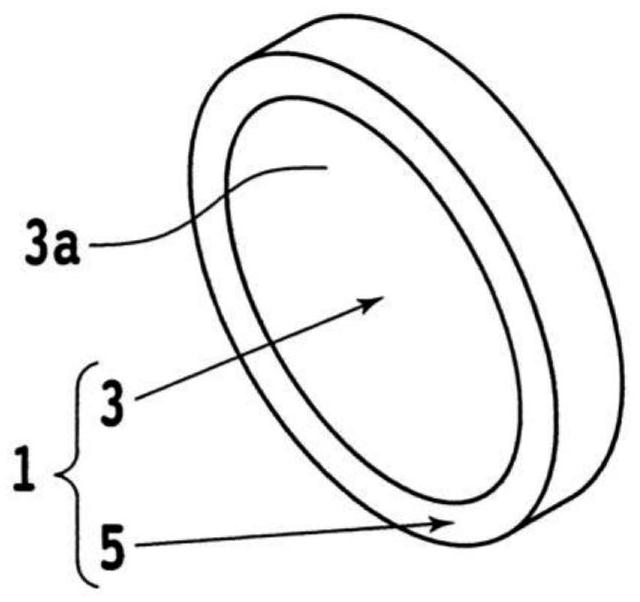

[0027] Embodiments of the present invention will be described with reference to the drawings. figure 1 It is a perspective view of the optical element unit 1 of this embodiment. Such as figure 1 As shown, the optical element unit 1 includes a disc-shaped reflective optical element 3 and a support body 5 that supports the outer peripheral portion of the optical element 3 . The optical element 3 is typically a mirror or the like, and has a front surface 3a on which light is incident. The optical element 3 is arranged, for example, at a predetermined position in an optical system constituting a laser processing apparatus (not shown) or the like.

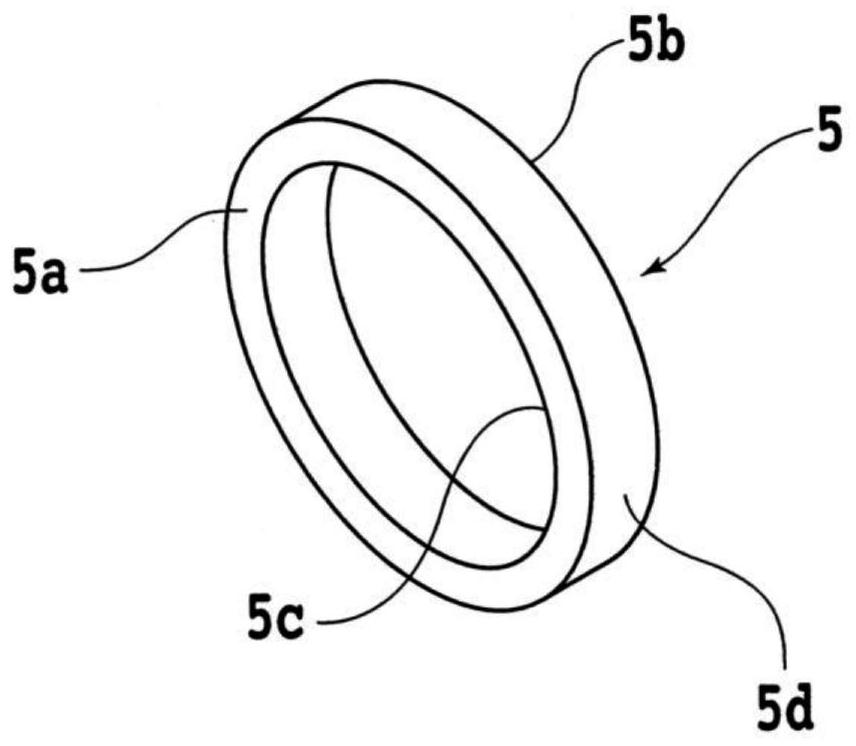

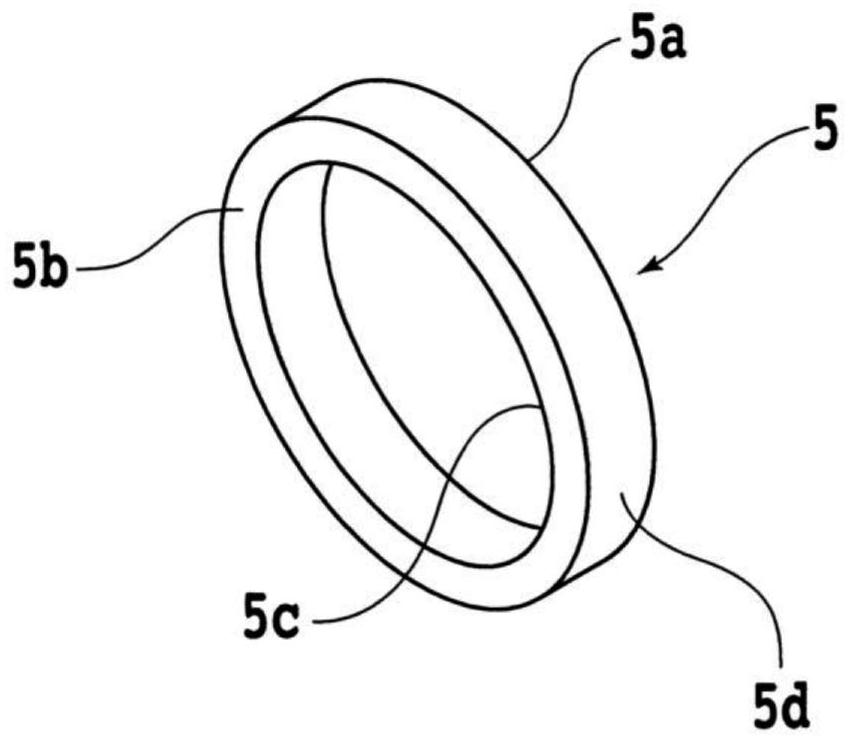

[0028] figure 2 is a perspective view of the support body 5 included in the optical element unit 1, image 3 is from with figure 2 The perspective view of the carrier 5 is viewed from the opposite direction. The support body 5 is formed into a cylindrical shape using, for example, aluminum, and has a first surface 5 a correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com