Emulsifying and dispersing machine

An emulsifying and dispersing, dispersing machine technology, applied in mixers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems that the upper raw materials cannot be sheared and emulsified, the effect of emulsification and dispersion is affected, and the material flow and mixing is slow. Achieve the effect of improving emulsification and dispersion efficiency, improving emulsification efficiency and production efficiency, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

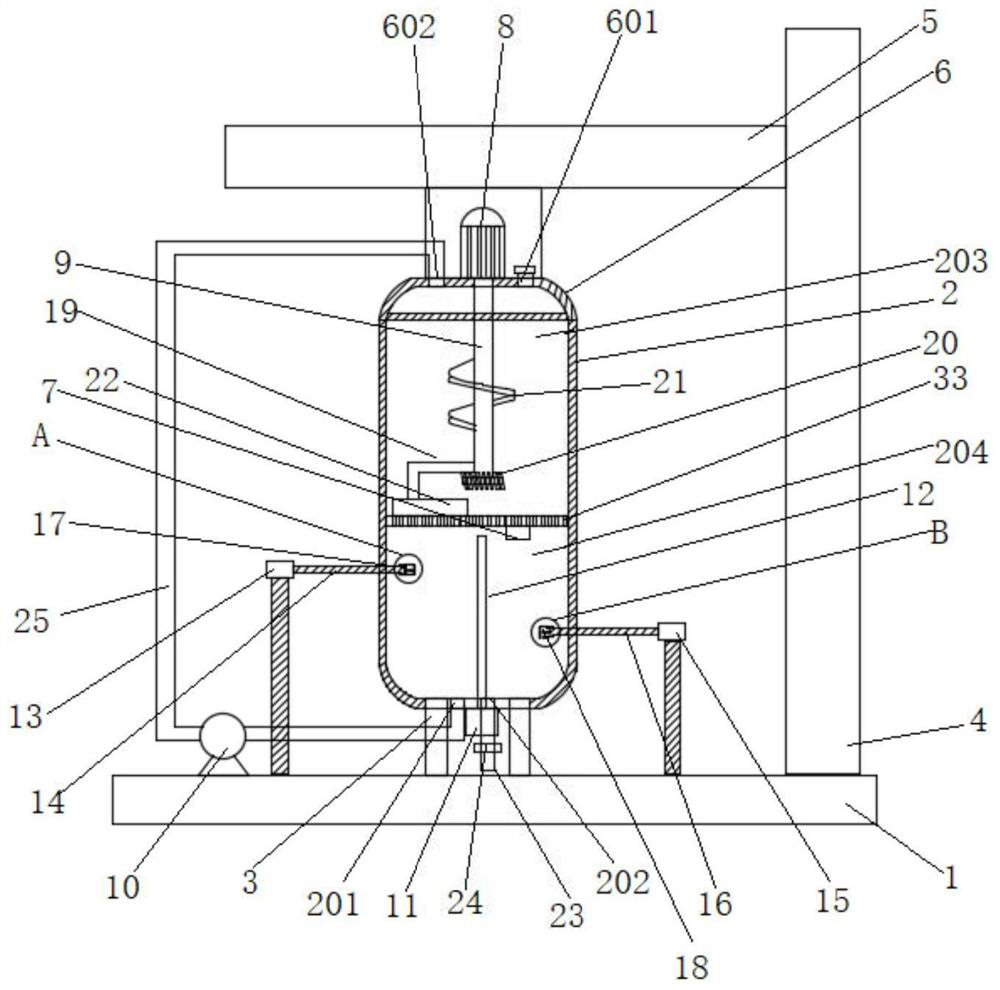

[0044] Such as figure 1 As shown, an emulsifying dispersing machine includes a fixed base 1, a kettle body 2 and an emulsifying and dispersing mechanism; the kettle body 2 is fixed on the upper end surface of the fixed base 1 through a shock absorbing support 3, and an electric telescopic column is also installed on the upper end surface of the fixed base 1 4. A support arm 5 is installed on the top of the electric telescopic column 4, and a kettle cover 6 for covering the kettle body 2 is installed on the lower end surface of the support arm 5; Dispersion zone 203, second emulsification dispersion zone 204.

[0045] In this embodiment, the bottom of the filter plate 33 is fixed with a vibrator 7 , through which the materials on the filter plate 33 are more conducive to entering the second emulsification and dispersion area 204 .

[0046] Such as Figure 4 As shown, the shock absorbing support 3 includes a fixed sleeve 3001, a bearing column 3002, a spring 3003 and a leg 300...

Embodiment 2

[0063] Such as Figure 5 and Figure 6 As shown, the structural difference between the emulsifying dispersing machine in this embodiment and Embodiment 1 is: in this embodiment, the first rotating shaft 9 is positioned at the bottom of the first emulsifying and dispersing area 203, and a U-shaped stirring blade 26 is provided, and the U-shaped stirring blade 26 is provided with an arc-shaped diversion notch 27 on the side facing the inner wall of the kettle body 2, and an arc-shaped diversion protrusion 28 distributed along the radial direction is provided on the inner wall of the kettle body 2, and the arc-shaped diversion protrusion The central axis of 28 is parallel to the central axis of the arc-shaped guide notch 27 and located on the same horizontal plane.

[0064] When the emulsification disperser in this embodiment is in use, the arc-shaped flow guide gap 27 on the U-shaped stirring blade 26 cooperates with the arc-shaped flow guide protrusion 28 on the inner wall of ...

Embodiment 3

[0066] Such as Figure 7 As shown, the structural difference between the emulsifying and dispersing machine in this embodiment and Embodiment 1 is that: in this embodiment, an insulating layer 29 is provided on the outer wall of the kettle body 2, and an electrical insulation layer 29 is arranged between the insulating layer 29 and the outer wall of the kettle body 2. The heating wire 30 and the temperature sensor 31 are installed on the inner wall of the second emulsification dispersion area 204 , and the fixed base 1 is also provided with a controller 32 , and the controller 32 is connected to the electric heating wire 30 and the temperature sensor 31 respectively.

[0067] Wherein, the controller 32 in this embodiment is a REX-C100 electronic temperature controller.

[0068] When the emulsifying disperser in this embodiment is in use, the temperature inside the kettle body 2 is controlled through the joint action of the electric heating wire 30, the temperature sensor 31 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap