Drilling equipment capable of automatically adjusting drilling angle

A technology for automatic adjustment and drilling equipment, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., and can solve problems such as affecting the adjustment of drill bits, slipping of transmission belts, and deviations in drilling accuracy. Achieve good water stain collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

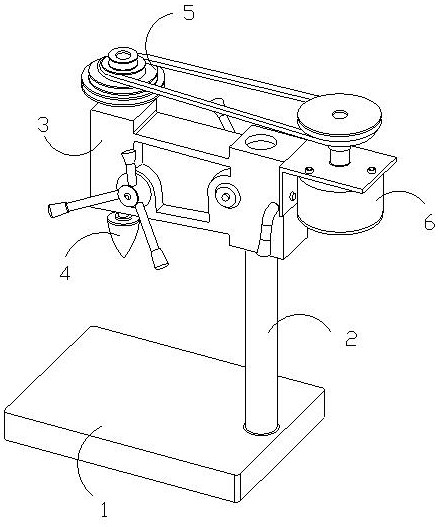

[0031] as attached figure 1 To attach Figure 7 Shown:

[0032] The present invention provides a kind of drilling equipment with automatic adjustment of drilling angle. The lower end is embedded in the support platform 1, the upper end of the vertical column 2 is connected with the adjustment column 3 and is movably matched, the drilling head 4 passes through the adjustment column 3 and moves below it, and the top frame 5 is installed on the adjustment column 3. The top position of the column 3, the motor 6 is fixedly installed on one side of the adjusting column 3.

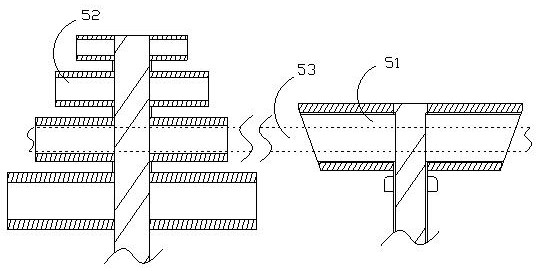

[0033] The top frame 5 is provided with a right axle platform 51, an adjustment platform 52, and a speed control transmission belt 53. The adjustment platform 52 is located at one side of the right axis platform 51, and the speed control transmission belt 53 is connected to the right axis by transmission. Platform 51, the outer periphery of adjustment frame platform 52 and movable cooperation.

[0034] Wherei...

Embodiment 2

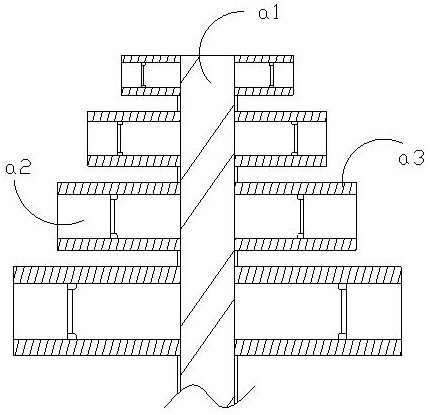

[0041] as attached Figure 8 To attach Figure 9 Shown:

[0042] Wherein, the inner abutment ring a33 is provided with a solid ring frame q1, an opening and closing plate q2, a telescopic frame q3, and a water collection cavity q4, and the solid ring frame q1 and the inner abutment ring a33 are an integrated structure and are arranged at its outer peripheral position. , the opening and closing plate q2 is hingedly connected to the solid ring frame q1, the water collection chamber q4 is located inside the solid ring frame q1, the telescopic frame q3 is connected between the solid ring frames q1 and is movably matched, and the solid ring frame q1 It is a ring structure with interval openings. There are eight telescopic frames q3, which are flexible. The opening and closing plates q2 are only opened inward. The water collection chamber q4 is in a hollow groove state. The telescopic frames The expansion and contraction deformation of q3 is beneficial to the circular displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com