Building construction waste crushing and recovering device

A recycling device, building construction technology, applied in grain processing, magnetic separation, solid separation, etc., can solve the problems of crusher damage, difficult to handle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

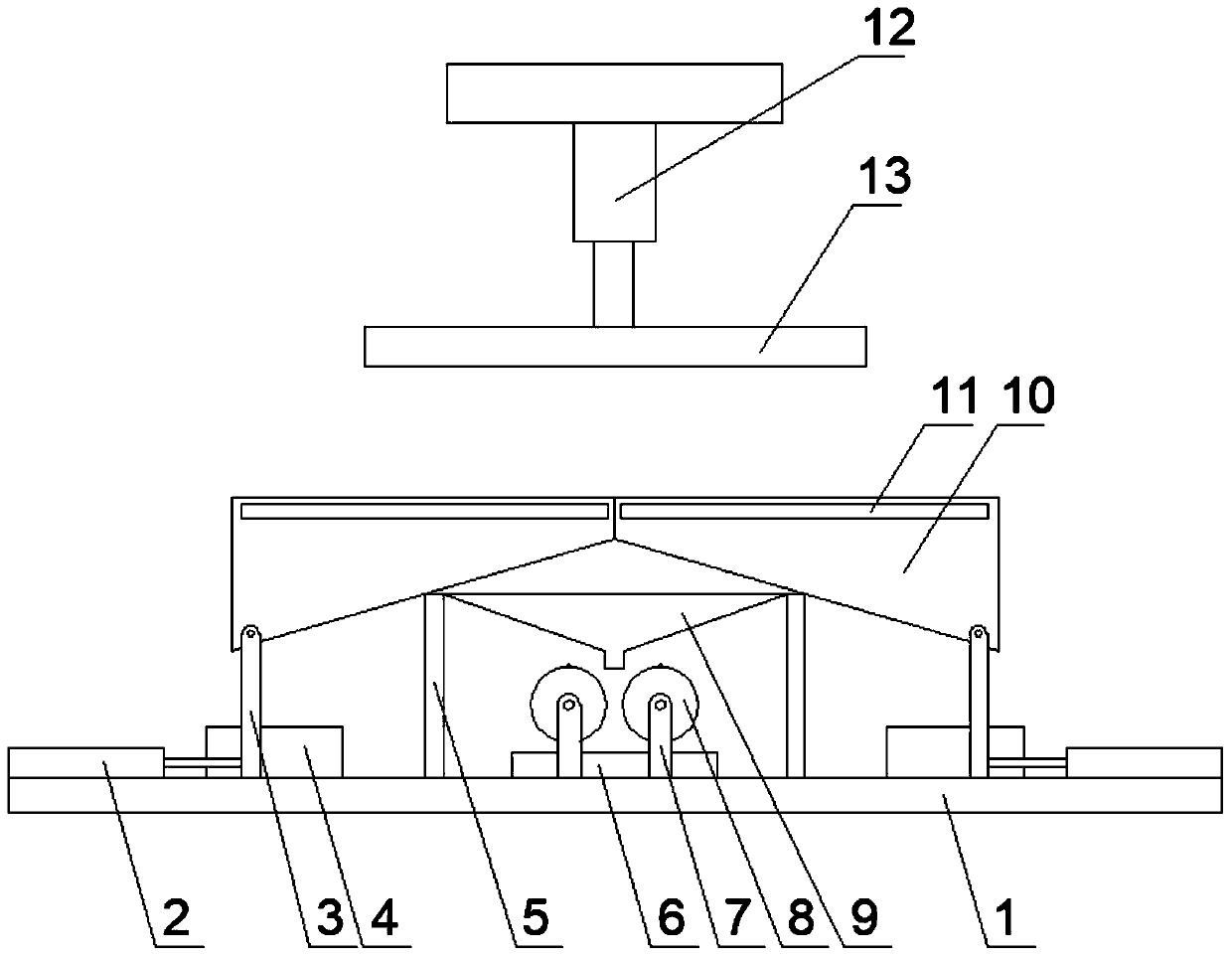

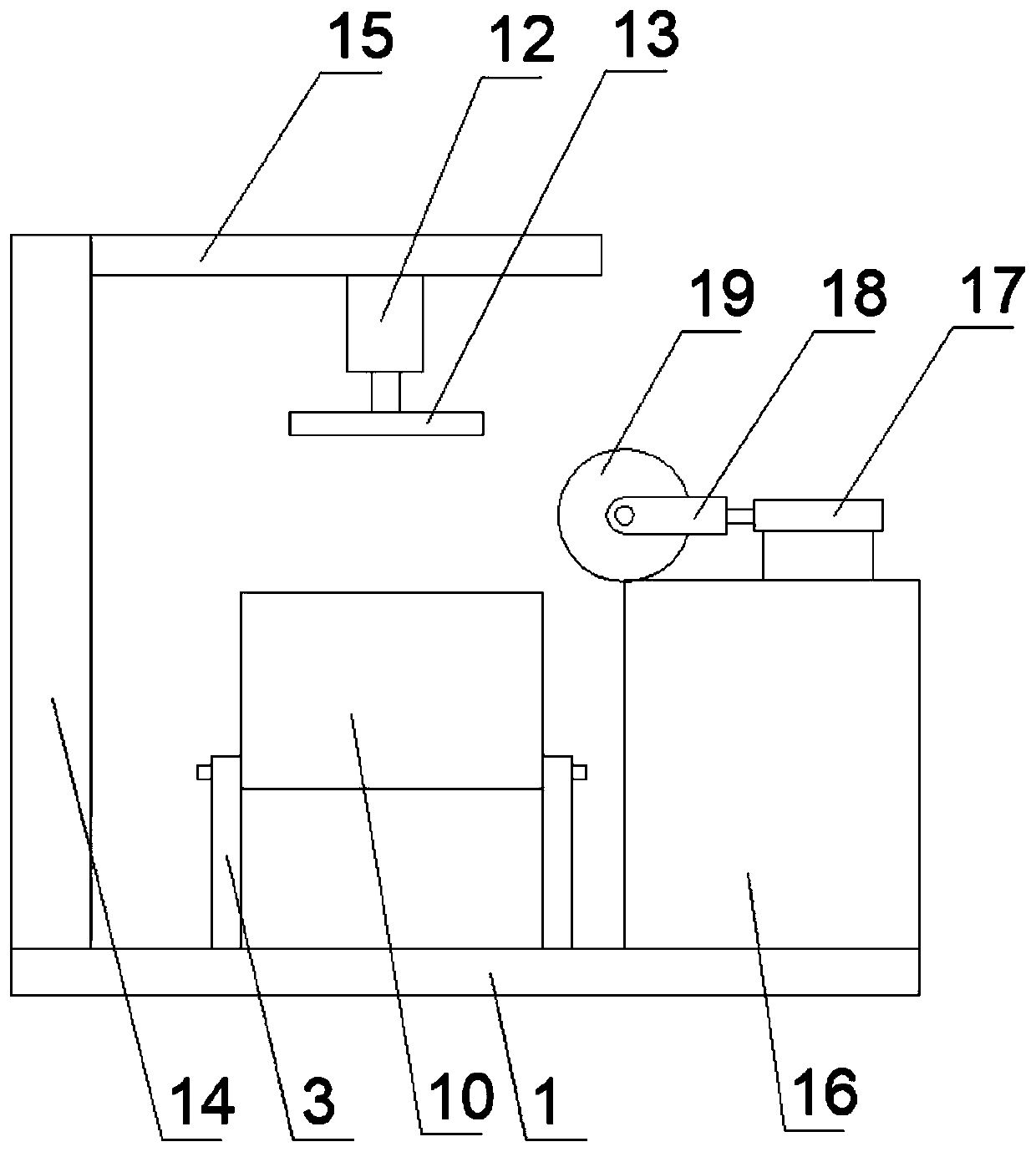

[0027] Such as figure 1 and figure 2 As shown, a construction waste crushing and recycling device in this embodiment includes an extrusion table, an extrusion crushing mechanism located above the extrusion table, and a rolling crushing mechanism located outside the extrusion table.

[0028] Extrusion platform comprises two bearing platforms 10, and the inner top of bearing platform 10 is fixed with electromagnet 11, and electromagnet 11 selects a piece of electromagnet roughly the same as bearing platform 10 area according to the area of bearing platform 10. The top surfaces of the bearing platforms 10 are all arranged horizontally, the bottom surfaces of the bearing platforms 10 are all inclined, and the high ends of the two bearing platforms 10 are offset, that is, the two bearing platforms 10 are spliced into an extrusion platform. A base 1 is installed below the bearing platform 10, and both sides below the bearing platform 10 are provided with an outer supporting co...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is: in this embodiment, the top of the inner support column 5 is rotatably connected with rollers, and the rollers are against the bottom surface of the bearing platform 10, and the bottom surface of the bearing platform 10 is supported by the rollers, which is convenient for the bearing platform 10 to move on. Swipe on the scroll wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com