Positioning tool for milling side wall of U-shaped workpiece

A technology for positioning tooling and workpieces, which is applied in the field of positioning tooling for side wall milling. It can solve the problems of no comparison files, large elastic deformation, and difficult locking and positioning, so as to improve processing efficiency and processing accuracy, and facilitate positioning and disassembly. Avoid the effect of inward bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

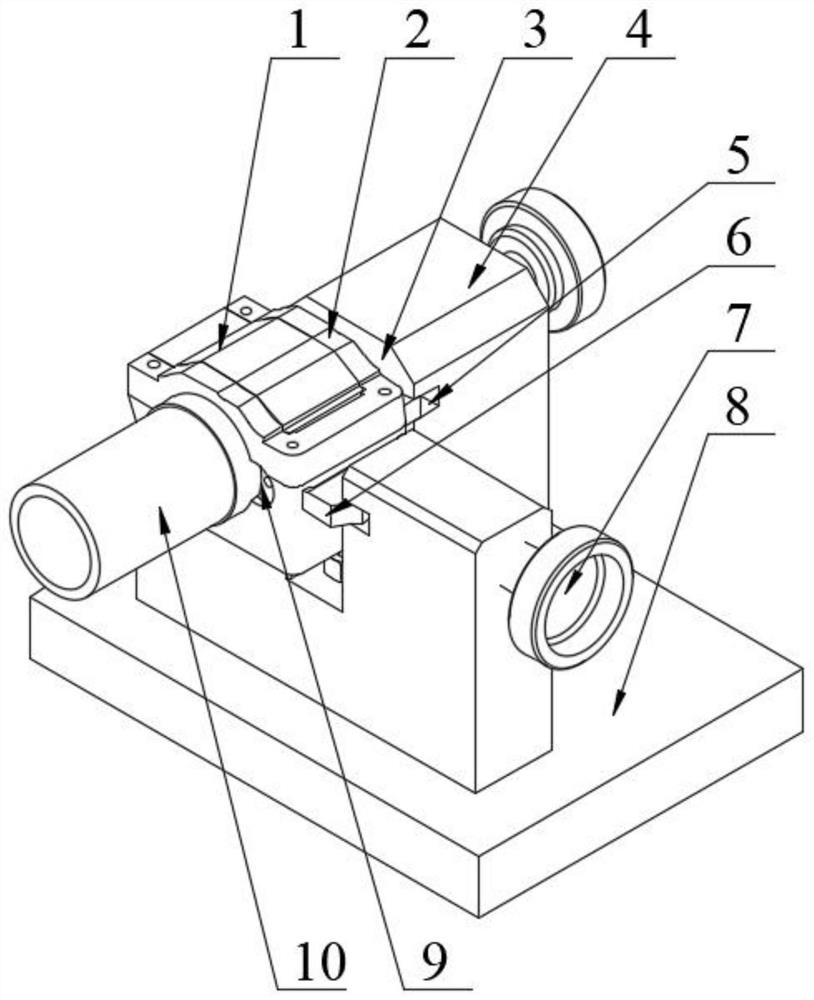

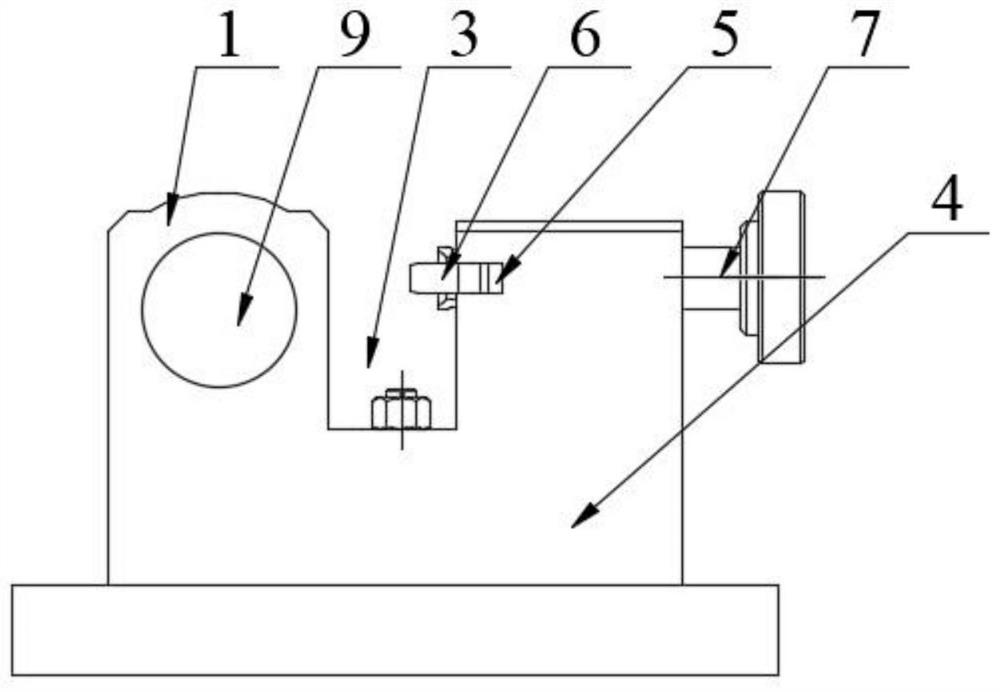

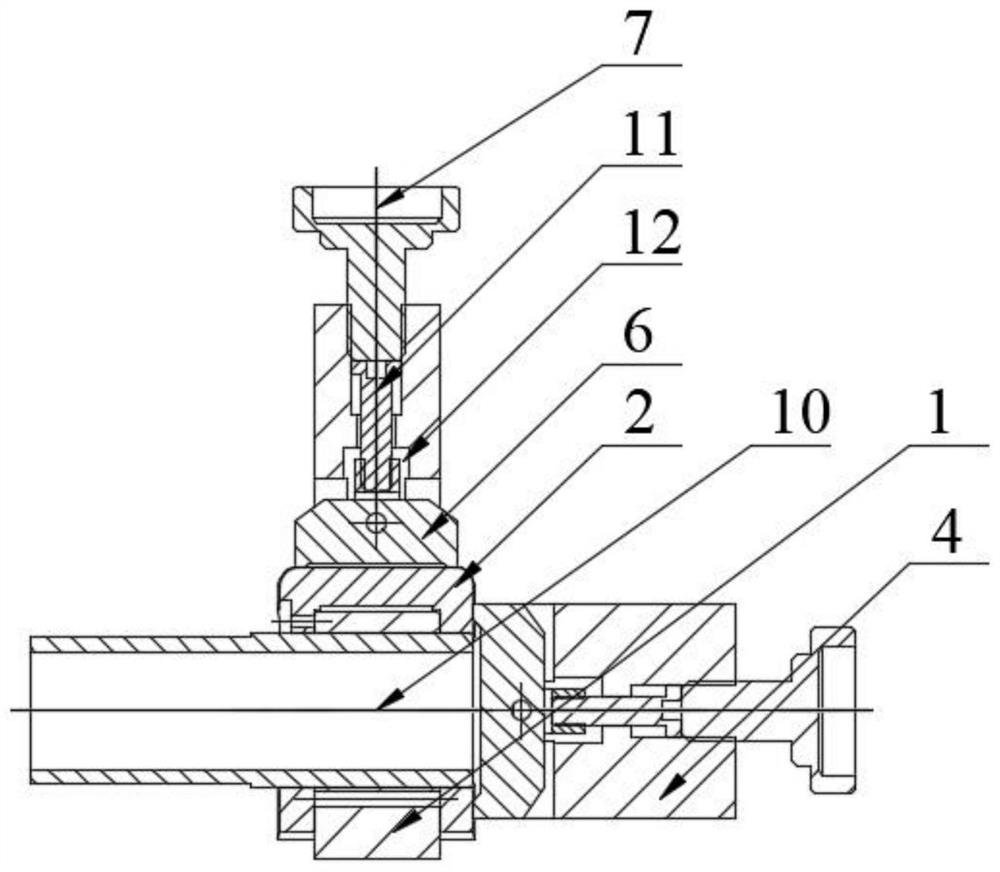

[0016] A positioning tool for side wall milling of a U-shaped workpiece. Coaxial reserved holes are formed on the two straight side walls of the U-shaped workpiece 2. The positioning tool includes a bottom plate 8 fixed on the top surface of the bottom plate. There is a right-angle bracket 4; the middle corner of the right-angle bracket is integrally made with a workpiece positioning seat 1 for suit positioning U-shaped workpieces, and the middle part of the two right-angle sides on the top surface of the right-angle bracket is provided with a relief groove 3, and the two right-angle brackets A through hole 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com