An injection mold with auto door buckle and gasket self-assembly function

A technology for injection molds and door panel clips, applied in springs/shock absorbers, vibration suppression adjustment, mechanical equipment, etc., can solve problems such as restricting the production and processing efficiency of automobile door panel clips, low manual assembly efficiency, and waste of human resources. , to reduce labor and labor costs, improve production and processing efficiency, and avoid thermal damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

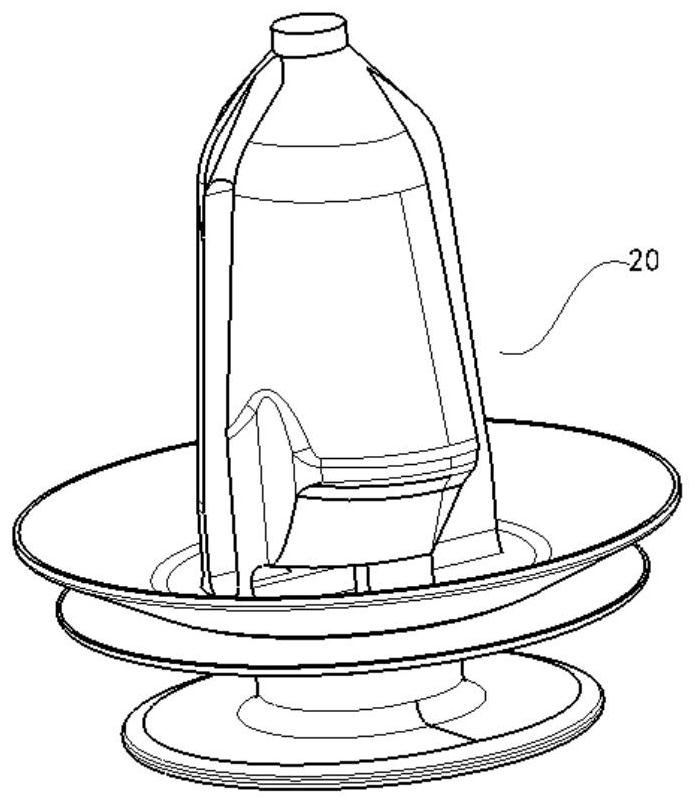

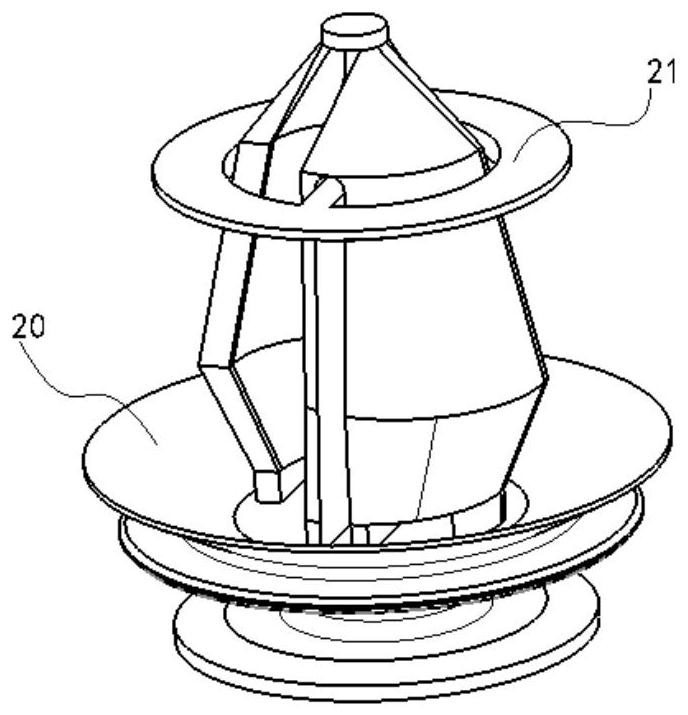

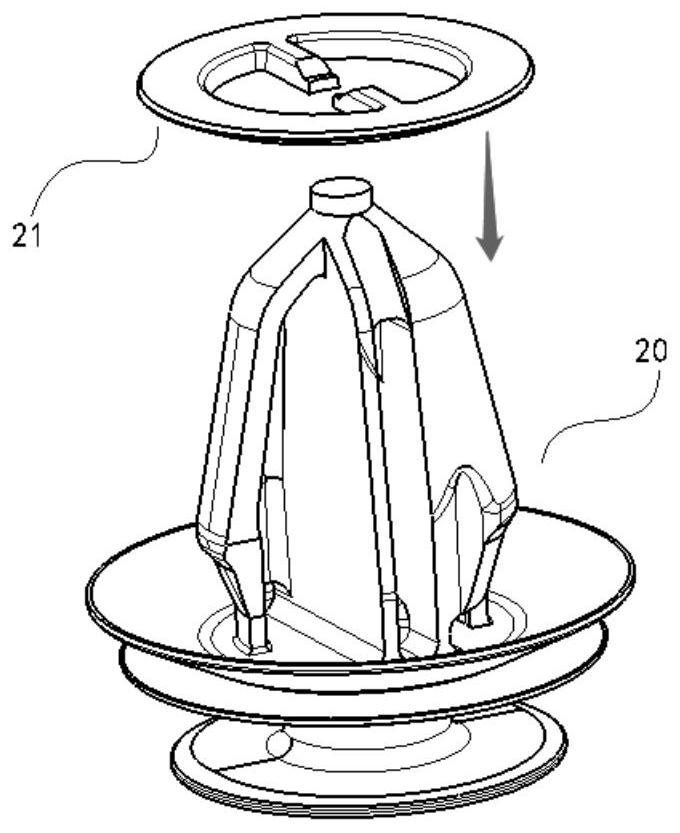

[0053] Such as Figure 4-21As shown, the present invention is an injection mold with self-assembly functions of automobile door panel snaps and gaskets, including an upper fixing plate 1, a stripping plate 2, a mother template 3, and an assembly spring block that are arranged correspondingly from top to bottom. 4. The male template 5, the thimble plate assembly 6 and the lower fixed plate assembly 7, the four corner positions of the lower end surface of the upper fixed plate 1 are respectively vertically fixed with first guide columns 8, and the first guide columns 8 The lower end is fitly installed in the bushing at the top corner of the lower fixing plate assembly 7, and the stripping plate 2, the female template 3 and the male template 5 are all slidably socketed on the first guide column through the vertical through hole at the top corner 8, the center of the upper fixing plate 1 is provided with a sprue sleeve 1-1, the center of the stripping plate 2 is provided with a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com